High temperature resistant polyol ester basic oil and preparation method thereof

A technology of polyol ester and base oil, which is applied in the direction of base material, petroleum industry, lubricating composition, etc. It can solve the problems of differences in high temperature resistance, structure and performance, etc., and achieve the effect of excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing the high-temperature-resistant polyol ester base oil described in the technical solution, comprising the following steps:

[0028] a) In the presence of an esterification catalyst, the polyhydric alcohol and the mixed fatty acid are mixed and reacted to obtain a high temperature resistant polyol ester base oil.

[0029] In the preparation method provided by the invention, firstly, the polyhydric alcohol and the mixed fatty acid are mixed and reacted in the presence of an esterification catalyst. Wherein, the specific types and dosage ratios of the polyols and mixed fatty acids have been introduced above, and will not be repeated here. In the present invention, the esterification catalyst includes but not limited to sulfur catalyst, metal catalyst or solid acid catalyst; the sulfur catalyst is preferably sodium bisulfate; the metal catalyst is preferably tin catalyst, more preferably tin chloride. In the presen...

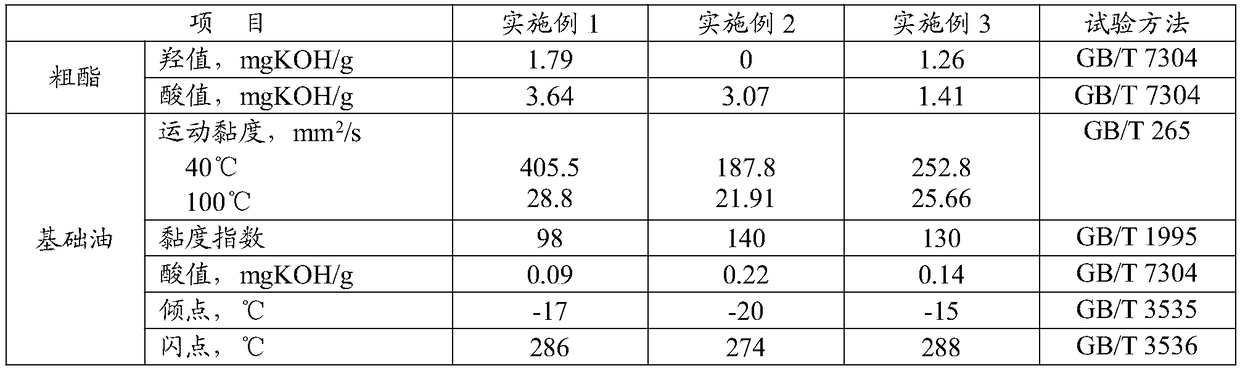

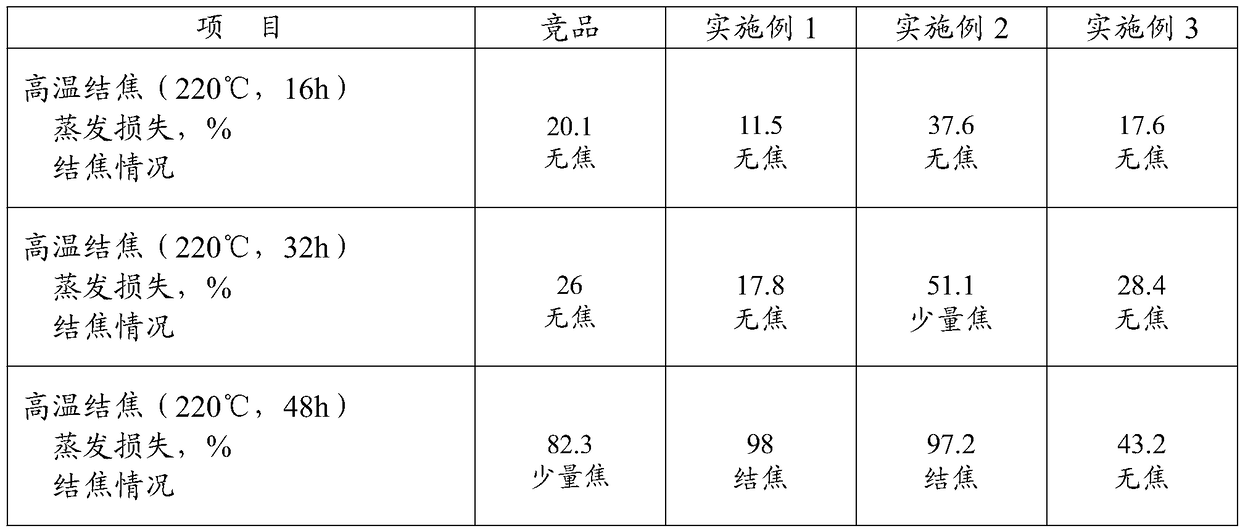

Embodiment 1

[0034] Feed tripentaerythritol and dipentaerythritol in a molar ratio of 1:1, determine the amount of fatty acid added according to the total number of hydroxyl moles, the excess of fatty acid is 30%, and select n-heptanoic acid, n-octanoic acid and isononanoic acid to feed in a mass ratio of 2:1:17 , add 0.5wt% activated carbon loaded with sodium bisulfate (the mass ratio of activated carbon to sodium bisulfate is 5:1), raise the temperature of the above-mentioned mixed system to 200-220° C. in 6 hours, and keep the temperature for 4 hours. After the reaction is finished, the crude ester is obtained, and the acid value and hydroxyl value of the crude ester are analyzed.

[0035] Alkali washing and water washing are used in the post-treatment stage of crude ester. The amount of lye added is determined according to the acid value of the crude ester. The concentration of lye is generally 20-40wt%. 0.1-1.5wt% activated carbon, until no water drops obviously flow out, then vacuum ...

Embodiment 2

[0037] Feed tripentaerythritol as 100%, determine the amount of fatty acid added according to the total number of moles of hydroxyl groups, the excess of fatty acid is 30%, and the fatty acid is selected from n-heptanoic acid, n-octanoic acid, isononanoic acid and n-nonanoic acid in a mass ratio of 3:5:8:4. , add 0.6wt% activated carbon loaded with tin chloride (the mass ratio of activated carbon to tin chloride is 5:1), raise the temperature of the above mixed system to 210-230° C. for 9 hours, and keep the temperature for 3 hours. After the reaction is finished, the crude ester is obtained, and the acid value and hydroxyl value of the crude ester are analyzed.

[0038] Alkali washing and water washing are used in the post-treatment stage of crude ester. The amount of lye added is determined according to the acid value of the crude ester. The concentration of lye is generally 20-40wt%. 0.1-1.5wt% of neutral alumina, until no water drops obviously flow out, and then vacuum fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com