Friction improver with nano mesoporous carbon and preparation method of friction improver

A friction modifier and nano-mesoporous technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor thermal stability, general anti-friction effect, easy settlement and blockage of oil passages, etc., to improve performance, increase affinity Oiliness, effect of preventing sludge coagulation and insoluble matter deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

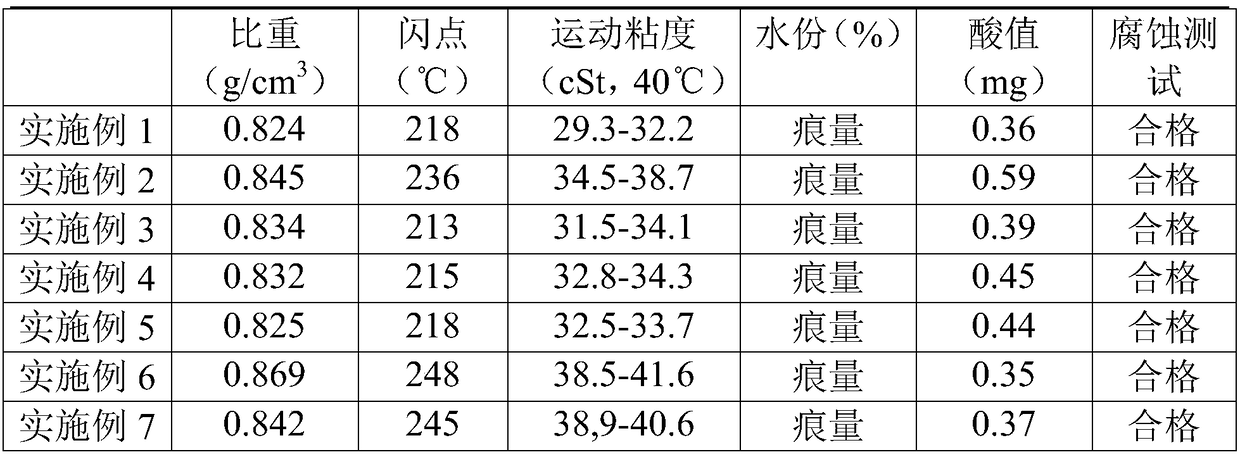

Embodiment 1

[0036] This embodiment provides a friction modifier containing nano-mesoporous carbon and a preparation method of the friction modifier containing nano-mesoporous carbon.

[0037] The friction modifier containing nano-mesoporous carbon described in this embodiment is prepared from the following raw materials in mass percentage:

[0038] Nano mesoporous carbon: 0.6%; Nano artificial graphite: 1.8%; Ashless dispersant: 3.5%; Organic molybdenum compound: 0.4%; Antioxidant: 0%; Base oil: balance.

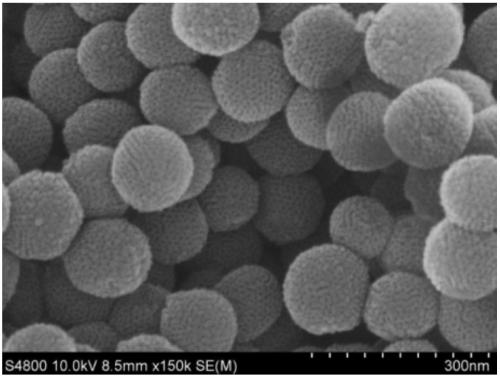

[0039] Nano mesoporous carbon is spherical or cylindrical nano mesoporous carbon with a particle size of 25nm.

[0040] Nano-artificial graphite is high-purity spherical artificial graphite with a purity of 99.9% and a particle size of 0.5 μm.

[0041] The ashless dispersant is polyisobutylene succinate.

[0042] The organomolybdenum compound consists of equal mass of oxymolybdenum dialkyldithiophosphate and molybdenum dialkyldithiocarbamate.

[0043] The base oil is a fully syntheti...

Embodiment 2

[0057] This embodiment provides a friction modifier containing nano-mesoporous carbon and a preparation method of the friction modifier containing nano-mesoporous carbon.

[0058] The friction modifier containing nano-mesoporous carbon described in this embodiment is prepared from the following raw materials in terms of mass percentage: nano-mesoporous carbon: 1.2%; nano-artificial graphite: 2.4%; ashless dispersant: 4.5%; organic Molybdenum compound: 0.6%; antioxidant: 0.3%; base oil: balance.

[0059] Nano mesoporous carbon is spherical or cylindrical nano mesoporous carbon with a particle size of 25nm.

[0060] Nano-artificial graphite is high-purity spherical artificial graphite with a purity of 99.9% and a particle size of 0.5 μm.

[0061] The ashless dispersant is borated polyisobutylene succinimide.

[0062] The organomolybdenum compound consists of equal mass of oxymolybdenum dialkyldithiophosphate and molybdenum dialkyldithiocarbamate.

[0063] Antioxidant is zinc ...

Embodiment 3

[0076] This embodiment provides a friction modifier containing nano-mesoporous carbon and a preparation method of the friction modifier containing nano-mesoporous carbon.

[0077] The friction modifier containing nano-mesoporous carbon described in this example is prepared from the following raw materials in terms of mass percentage: nano-mesoporous carbon: 1.2%; nano-artificial graphite: 1.8%; ashless dispersant: 4.0%; organic Molybdenum compound: 0.8%; antioxidant: 0.5%; base oil: balance.

[0078] Nano mesoporous carbon is spherical or cylindrical nano mesoporous carbon with a particle size of 25nm.

[0079] Nano-artificial graphite is high-purity spherical artificial graphite with a purity of 99.9% and a particle size of 0.5 μm.

[0080] The ashless dispersant is borated polyisobutylene succinimide.

[0081] The organic molybdenum compound is composed of oxymolybdenum dialkyl dithiophosphate and molybdenum dialkyl dithiocarbamate with a mass ratio of 1:2.

[0082] Antio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com