Separating and recycling method for nickel-plated copper wire

A technology for separation and recovery, nickel-plated copper, which is used in the improvement of process efficiency, the preparation of liquid hydrocarbon mixtures, the petroleum industry, etc. Short, simple method, avoid the effect of metal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

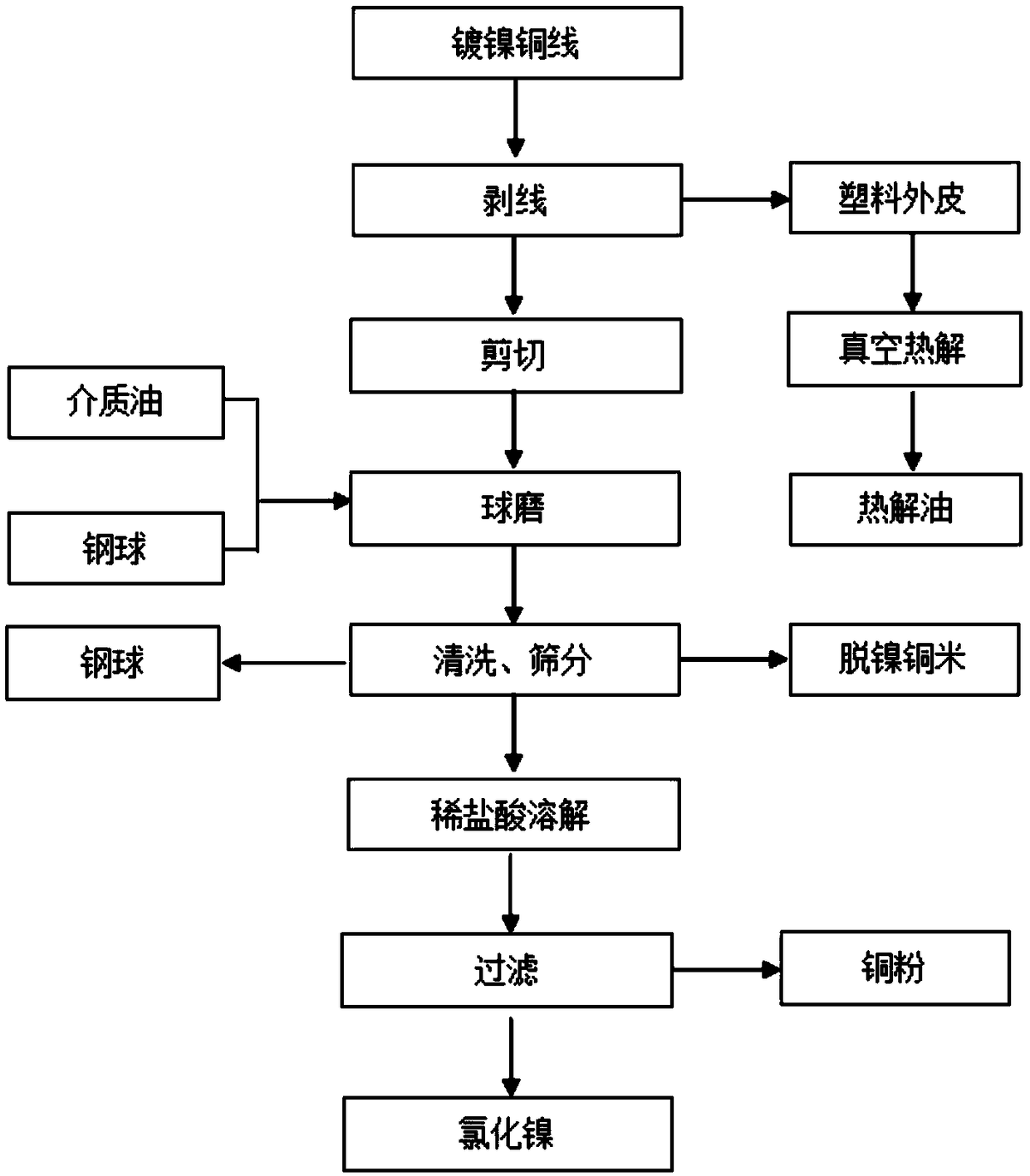

Method used

Image

Examples

Embodiment 1

[0025] Send the nickel-plated copper wire with an inner core diameter of 2-5mm into the wire stripping machine, separate the plastic sheath on the surface of the copper-nickel copper wire, and put the plastic sheath into a vacuum pyrolysis reaction device for pyrolysis. The pyrolysis temperature is 350 ℃, the reaction pressure is 2KPa, and the pyrolysis oil is obtained; the nickel-plated copper wire stripped of the plastic sheath is sheared by a copper rice machine to obtain a nickel-plated copper rice with a length of 1-3cm; the 1.2Kg nickel-plated copper rice After mixing with 1 kg of steel balls with a diameter of 30 mm and 0.05 kg of silicone oil, add them to a vertical stirring ball mill. The speed of the ball mill is 300 r / min and the ball mill is treated for 30 minutes. The nickel coating and a small amount of copper on the surface of the nickel-plated copper rice are peeled off; Take out the materials in the ball mill, wash and sieve with alcohol to obtain a mixture of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com