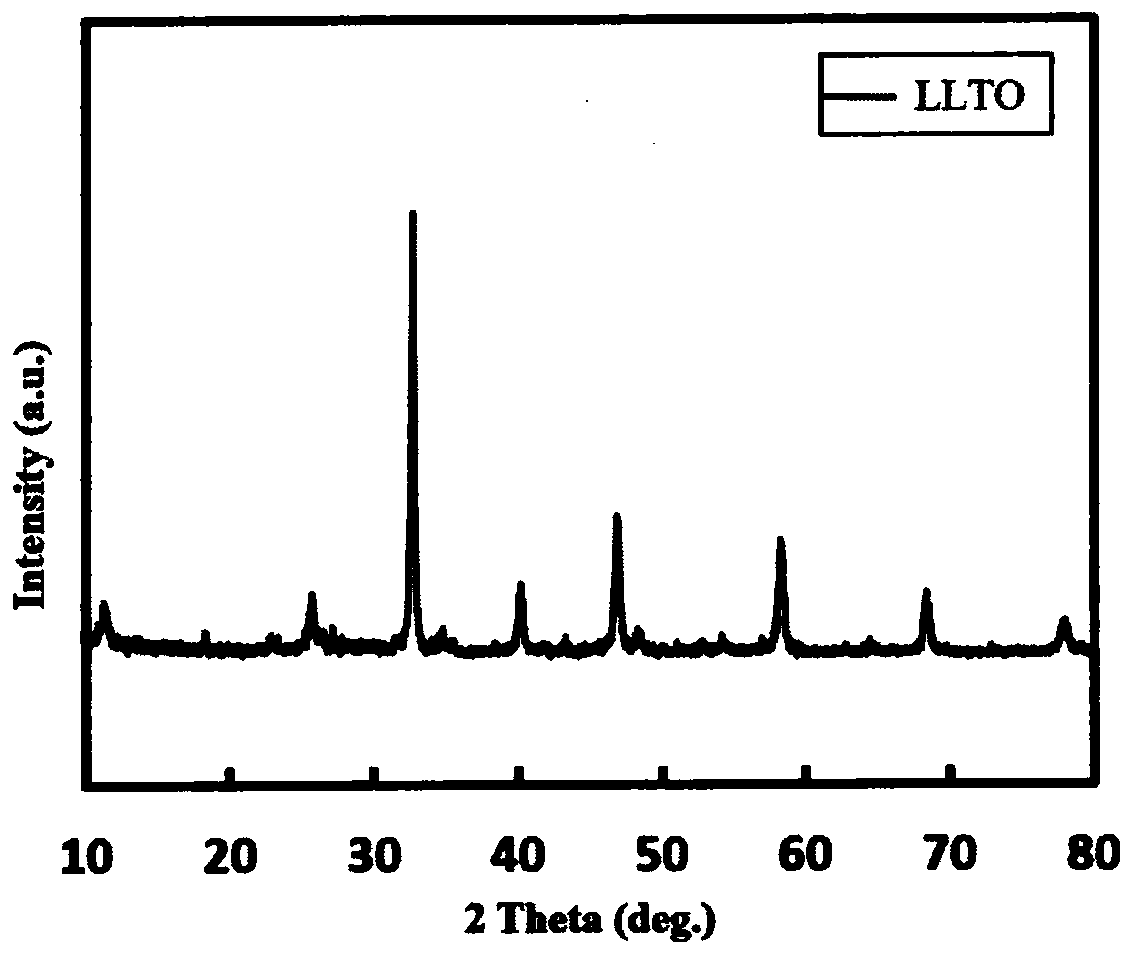

Flexible lithium lanthanum titanyl ceramic nanofiber membrane and preparation method thereof

A nanofiber membrane, lithium lanthanum titanium oxide technology, applied in fiber treatment, heating/cooling fabrics, electrical components, etc., can solve the problem of poor compatibility between ceramic electrolyte and electrode interface, reduced battery coulombic efficiency and life, complex preparation process, etc. problems, to achieve the effect of rich raw materials, increased electronic conductivity, and low material synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A flexible lithium lanthanum titanium oxide ceramic nanofiber membrane is composed of lithium lanthanum titanium oxide nanofibers, and the structural formula of the lithium lanthanum titanium oxide compound is Li 3x La 2 / 3-x TiO 3 , where X is 0.11.

[0040] The preparation method of the above-mentioned flexible lithium lanthanum titania ceramic nanofiber membrane, the specific steps are:

[0041] Step 1: Prepare a precursor solution consisting of lithium source, lanthanum source, titanium source, polymer and volatile organic solvent: dissolve the polymer polyethylene oxide (Aladdin, 600,000) in Solvent glacial acetic acid and N,N-dimethylformamide (the molar ratio of glacial acetic acid and N,N-dimethylformamide is 3:1) and stirred for 60min, then added lithium source lithium chloride, lanthanum source chlorine Lanthanum chloride and titanium source tetrabutyl titanate were stirred for 120 minutes and mixed evenly to prepare a precursor solution, wherein the molar r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com