Paper wood

A paper and fresh technology, applied in the field of paper materials, can solve the problems of irreplaceable plastic lunch boxes, poor heat resistance of paper lunch boxes, burns by delivery staff and users, etc., which is conducive to sustainable development, eliminates white pollution, Maintain long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

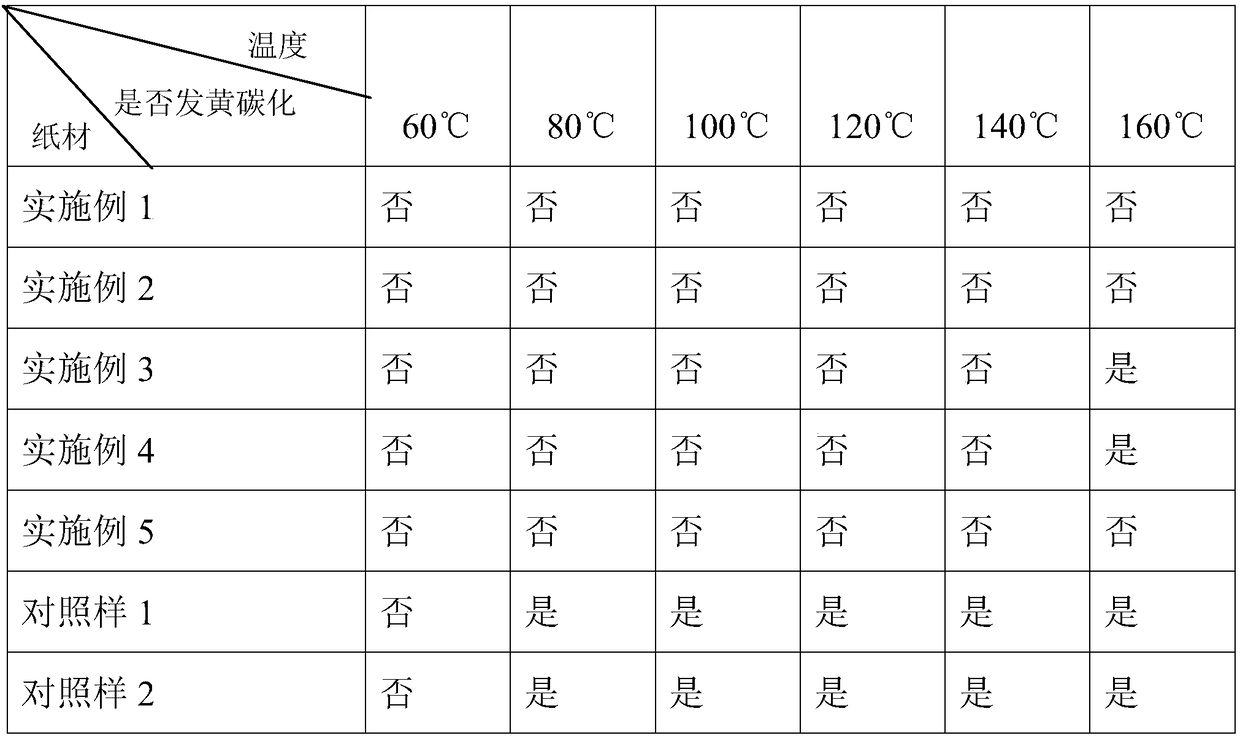

Examples

Embodiment 1

[0022] A paper material, comprising the following components by weight: 25% of dry leaves, 20% of fresh leaves, 8% of leaf skin, 37% of vein fibers, 2% of pectin, 3% of gum, and 5% of modified starch. Dry leaves adopt two kinds of dry leaves of magnolia tree and dry leaves of linden tree, and the weight ratio of the two is 1:1; fresh leaves adopt three kinds of fresh leaves of magnolia tree, fresh leaves of linden tree and fresh leaves of pine tree, and the weight ratio of the three is 2: 2:1; leaf epidermis adopts linden leaf epidermis; leaf vein fiber adopts linden leaf vein fiber and sycamore leaf vein fiber, and the weight ratio of the two is 1:1; the above-mentioned gum is gum arabic.

[0023] The preparation method is:

[0024] Get magnolia dry leaves 12.5kg, linden dry leaves 12.5kg, magnolia fresh leaves 8kg, linden fresh leaves 8kg, pine fresh leaves 4kg, linden leaf epidermis 8kg, linden vein fiber 18.5kg and sycamore leaf vein fiber 18.5kg to grind into powdery. T...

Embodiment 2

[0026] A paper material, comprising the following components by weight: 28% of dry leaves, 18% of fresh leaves, 12% of leaf skin, 30% of vein fibers, 5% of gum, and 7% of modified starch. Two kinds of dry leaves of linden tree and dry leaves of loquat tree are used for dry leaves, and the weight ratio of the two is 1:1; fresh leaves of magnolia tree and fresh leaves of pine tree are used, and the weight ratio of the two is 1:1; the skin of the leaves is made of Magnolia leaf epidermis, diamond vine leaf epidermis and Chinese phoenix tree leaf epidermis three kinds, the weight ratio of the three is 1:1:1; The leaf vein fiber adopts magnolia leaf vein fiber and poplar leaf vein fiber, and the weight ratio of the two is 1: 1; the above-mentioned gum adopts gum tragacanth.

[0027] The preparation method is:

[0028] Get 14kg of linden dry leaves, 14kg of loquat dry leaves, 9kg of fresh leaves of magnolia tree, 9kg of fresh leaves of pine tree, 4kg of magnolia leaf epidermis, 4kg...

Embodiment 3

[0030] A paper material, comprising the following components by weight: 20% of dry leaves, 15% of fresh leaves, 20% of leaf skin, 24% of vein fibers, 5% of pectin, 10% of gum, and 6% of modified starch. Above-mentioned dry leaf adopts magnolia tree dry leaf, linden dry leaf and pine dry leaf three kinds, and the weight ratio of the three is 2:2:1; Above-mentioned fresh leaf adopts linden fresh leaf; Above-mentioned leaf epidermis adopts linden leaf epidermis and Poplar leaf epidermis, the weight ratio of the two is 1:1; Above-mentioned leaf vein fiber adopts magnolia leaf vein fiber; Above-mentioned gum adopts two kinds of peach gum and larch arabinogalactan, and the weight ratio of the two is 1: 1.

[0031] The preparation method is:

[0032] Get magnolia dry leaf 8kg, linden dry leaf 8kg, pine dry leaf 4kg, linden fresh leaf 15kg, pine fresh leaf 4kg, linden leaf epidermis 10kg, poplar leaf epidermis 10kg, magnolia leaf vein fiber 24kg, grind into powder. Then add a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com