A Te/MoS2 van der Waals heterostructure and preparation method and application thereof

A heterogeneous structure, nanosheet technology, applied in the direction of final product manufacturing, sustainable manufacturing / processing, nanotechnology for materials and surface science, etc., can solve the problem of slow response speed, achieve fast response time, The effect of low cost and fast synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a Te / MoS 2 Van der Waals heterostructures, including MoS 2 nanosheet layer and Te nanowire layer, the Te nanowire layer is epitaxially grown on the MoS 2 nanosheet surface.

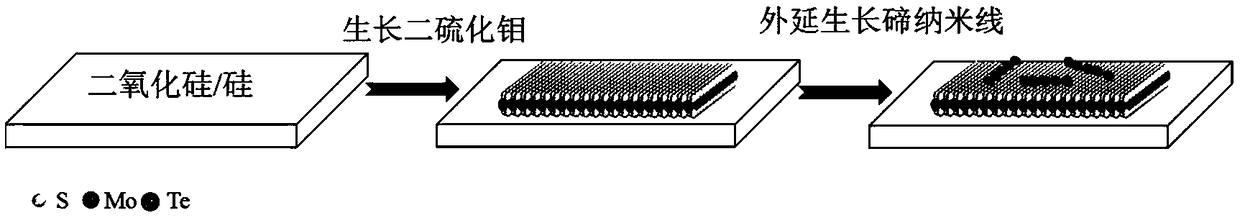

[0037] This embodiment also provides the above-mentioned Te / MoS2 The preparation method of van der Waals heterostructure (its flow chart is as figure 1 shown), including the following steps:

[0038] (1) Mix hydrogen peroxide and concentrated sulfuric acid at a ratio of 1:3 by volume, put the cut silicon chip into it, heat it at 140°C for 3 hours, and then use acetone, ethanol and deionized water to sonicate for 20 minutes each, Blow dry with nitrogen;

[0039] (2) MoO 3 powder and S powder are respectively placed in the downstream central temperature zone and upstream central temperature zone of the dual temperature zone tube furnace, and the silicon wafer is placed in MoO 3 Above the powder, after cleaning the quartz tube with argon, the temperature of the downstrea...

Embodiment 2

[0057] This embodiment provides a Te / MoS 2 Van der Waals heterostructures, including MoS 2 nanosheet layer and Te nanowire layer, the Te nanowire layer is epitaxially grown on the MoS 2 nanosheet surface.

[0058] This embodiment also provides the above-mentioned Te / MoS 2 A method for preparing a van der Waals heterostructure, comprising the following steps:

[0059] (1) Mix hydrogen peroxide and concentrated sulfuric acid at a ratio of 1:3 by volume, put the cut silicon chip into it, heat it at 140°C for 3 hours, and then use acetone, ethanol and deionized water to sonicate for 20 minutes each, Blow dry with nitrogen;

[0060] (2) MoO 3 powder and S powder are respectively placed in the downstream central temperature zone and upstream central temperature zone of the dual temperature zone tube furnace, and the silicon wafer is placed in MoO 3 Above the powder, after cleaning the quartz tube with argon, the temperature of the downstream central temperature zone was raised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com