A reflective electromagnetic shielding film for FPC and a preparation method thereof

An electromagnetic shielding film, reflective technology, applied in magnetic/electric field shielding, reflective/signal coatings, electrical components, etc., can solve the problems of low ink molecular weight, reduced shielding performance, broken metal layer and cracks, etc., to achieve good product flatness , Guaranteed bending resistance and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The first insulating paint layer, the second insulating paint layer and the coating of the electromagnetic wave reflection coating of the FPC reflective electromagnetic shielding film of the present invention use acrylic paint, and the manufacturing process that can be adopted is as follows.

[0062] The first step is to prepare the coatings of the first insulating coating layer, the second insulating coating layer and the electromagnetic wave reflecting coating, which can be prepared in the following order, but the scope of protection is not limited to the following order of A1, A2, A3.

[0063] A1, preparing the first insulating coating layer coating;

[0064] (1) Take 7 parts of acrylic acid, 20 parts of methyl acrylate, 45 parts of acrylonitrile, 20 parts of butyl acrylate, and 7 parts of isobornyl acrylate to obtain acrylic resin I through emulsion polymerization or solution polymerization or bulk polymerization, and add 0.3% to 1.2% persulfate, react at 50 to 60°C...

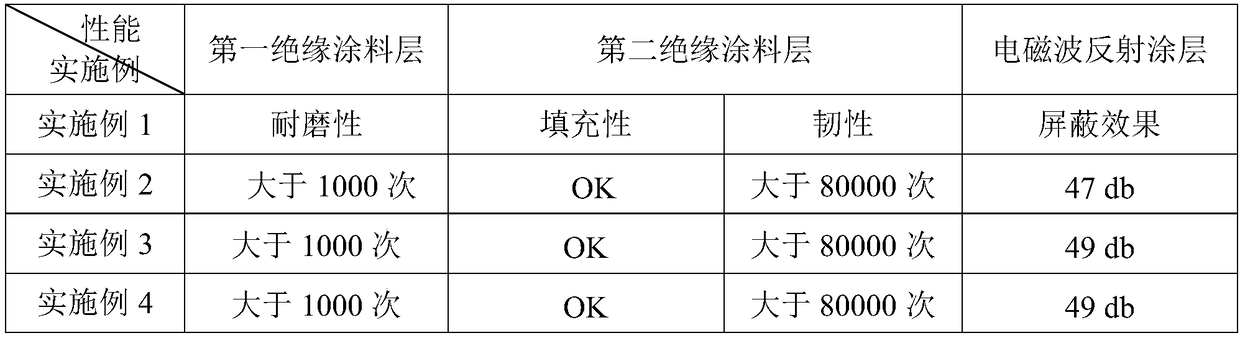

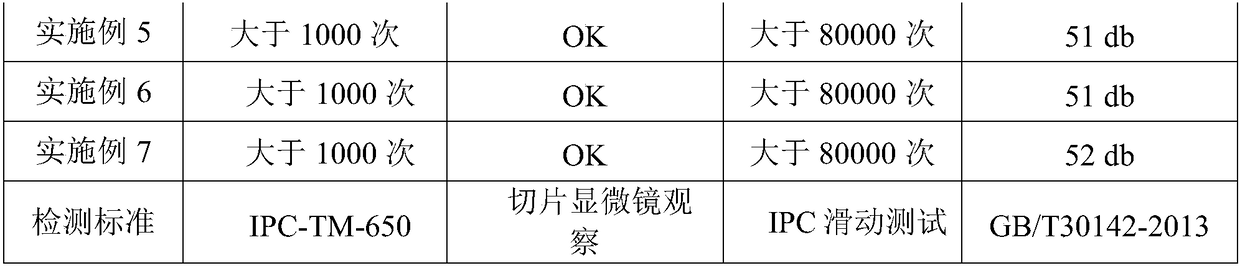

Embodiment 2

[0083] The manufacturing process of the reflective electromagnetic shielding film for FPC in this embodiment is basically the same as in Example 1, except that the first insulating coating layer coating in A1, the second insulating coating coating coating in A2, and the electromagnetic wave reflection coating coating in A3 Group ratio:

[0084] The proportioning of each raw material that makes acrylic resin I in A1 is different, and the addition amount of acrylic acid, methyl acrylate, acrylonitrile, butyl acrylate, and isobornyl acrylate are respectively 3, 10, 30, 10, 5 parts; The amounts of pigment carbon black, titanium dioxide and silicon oxide added to the acrylic resin I were 10%, 3%, and 5% respectively.

[0085] The ratio of each raw material that makes acrylic resin II in A2 is different, and the addition amount of acrylic acid, ethyl acrylate, butyl methacrylate, acrylonitrile is respectively 2, 10, 30, 5 parts; The amount of elastic microspheres is 10%, and the pa...

Embodiment 3

[0090] The manufacturing process of the reflective electromagnetic shielding film for FPC in this embodiment is basically the same as in Example 1, except that the first insulating coating layer coating in A1, the second insulating coating coating coating in A2, and the electromagnetic wave reflection coating coating in A3 Group ratio:

[0091] The ratios of the raw materials for the acrylic resin I obtained in A1 are different, and the additions of acrylic acid, methyl acrylate, acrylonitrile, butyl acrylate, and isobornyl acrylate are respectively 10, 30, 60, 30, and 10 parts; The amounts of pigment carbon black, titanium dioxide and silicon oxide added to the acrylic resin I were 20%, 10%, and 15% respectively.

[0092] The ratios of raw materials for the acrylic resin II obtained in A2 are different, and the addition amounts of acrylic acid, ethyl acrylate, butyl methacrylate, and acrylonitrile are respectively 5, 40, 60, and 10 parts; The amount of elastic microspheres i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com