Fluorine-chlorine removal tower and device and process for removing fluorine and chlorine from sulfuric acid by fluorine-chlorine removal tower

A technology for defluorinated chlorine tower and sulfuric acid, applied in the field of defluorinated chlorine tower, process and device for removing fluorine and chlorine in sulfuric acid, can solve problems such as complex process, limited concentration of polluted acid, debonding failure of lining, etc., and achieve high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

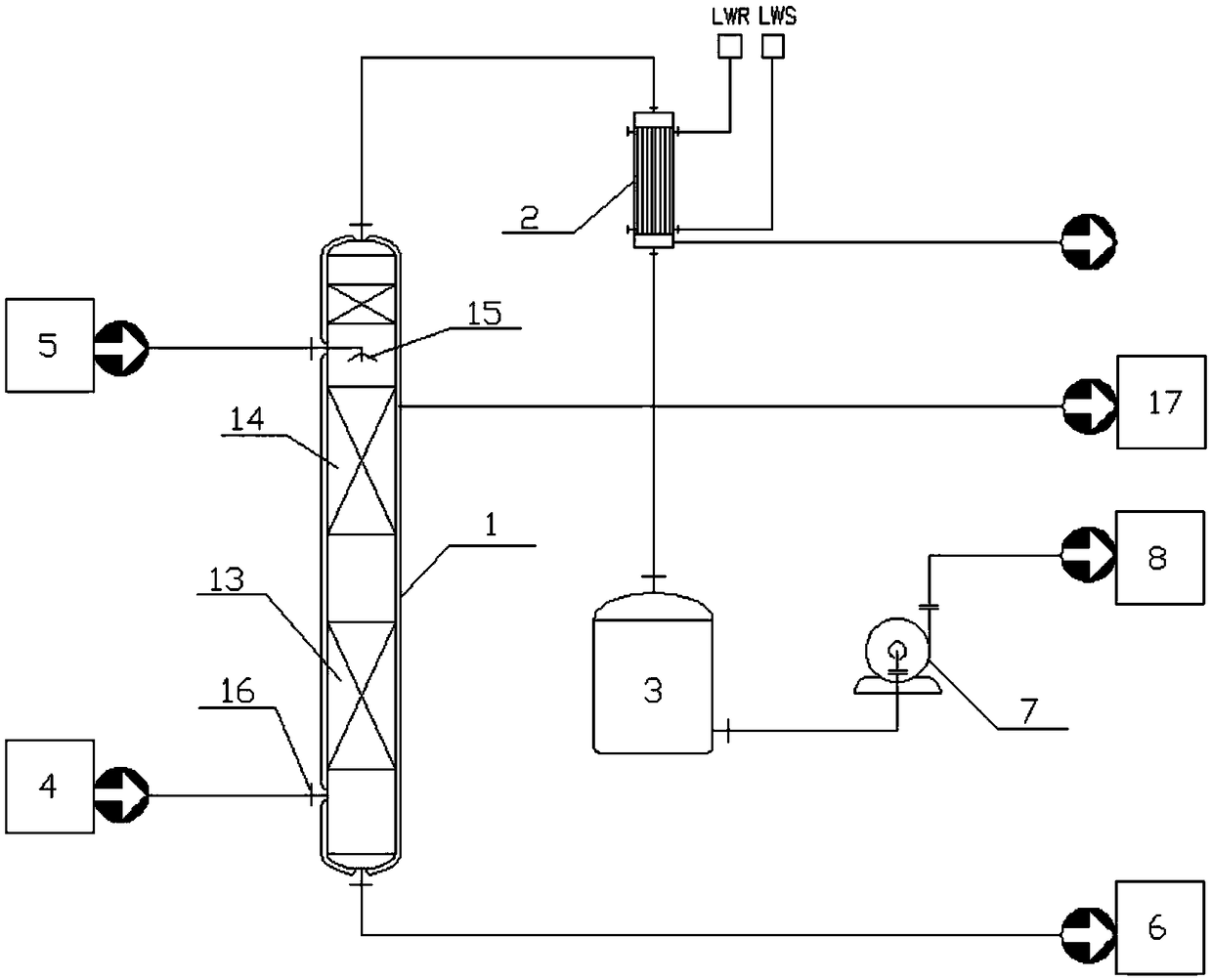

[0026] refer to figure 1 , figure 2 , a device for removing fluorine and chlorine in sulfuric acid, the device includes a defluorination chlorine tower 1, a condenser 2 and an intermediate tank 3, the lower part of the defluorination chlorine tower 1 communicates with a steam supply device 4, and the defluorination A steam valve 16 is arranged between the chlorine tower and the steam supply device; the top of the defluorination chlorine tower 1 communicates with the raw material tank 5, the top of the defluorination chlorine tower 1 communicates with the top of the condenser 2, and the bottom of the defluorination chlorine tower 1 communicates with the top of the condenser 2 The defluorinated chlorosulfuric acid storage tank 6 is connected; the bottom of the condenser 2 is connected with the top of the middle tank 3 , and the bottom of the middle tank 3 is connected with the recovery device 8 through the discharge pump 7 .

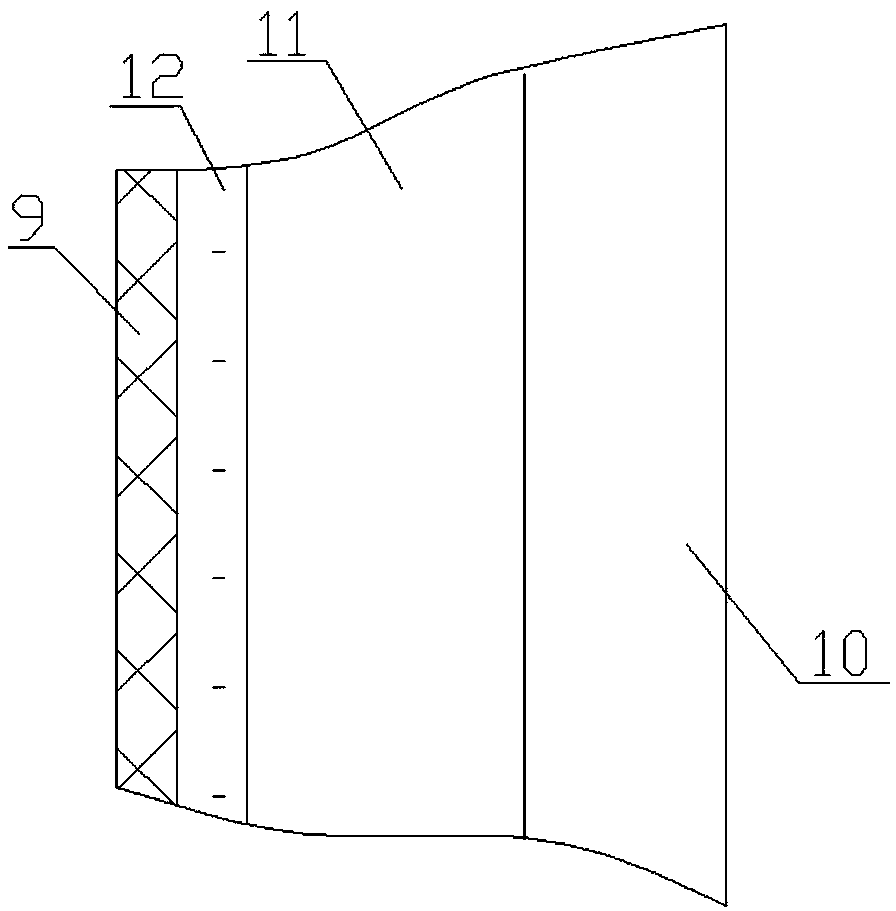

[0027] The tower wall of described defluorination ...

Embodiment 2

[0035] Certain sample is 75wt% sulfuric acid, contains 2% HF, adopts the device described in embodiment 1, feeds steam and blows off, the saturated steam pressure that is used for stripping is 0.3MPa (G), and tower internal pressure is 8KPa (A) , the temperature at the top of the tower is 84°C, the temperature at the bottom of the tower is 122°C, HF and water come out from the top of the tower, and the content of HF at the bottom of the tower is trace.

Embodiment 3

[0037] Certain sample is 90wt% sulfuric acid, contains 2% HF, adopts the device described in embodiment 1, feeds steam and blows off, the saturated steam pressure that is used for stripping is 0.5MPa (G), and tower internal pressure is 15KPa (A) , the temperature at the top of the tower is 90°C, the temperature at the bottom of the tower is 150°C, HF and water come out from the top of the tower, and the content of HF at the bottom of the tower is trace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com