Processing method for micro-nano structure of array of ultrafast laser combined pulse sequence

An ultra-fast laser and combined pulse technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting processing efficiency, many micro-nano structure processes, and inability to continue, so as to improve processing efficiency and improve processing efficiency. The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

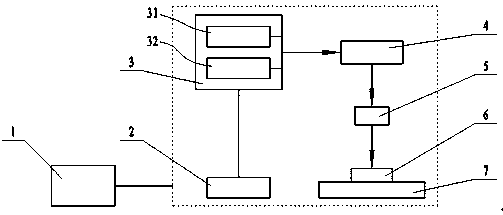

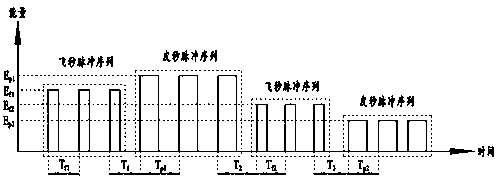

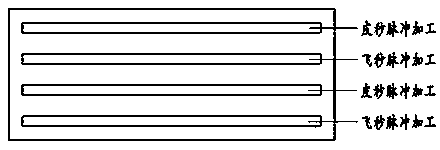

[0028] An array micro-nano structure processing method of an ultrafast laser combined pulse sequence, comprising the following steps: grinding and polishing the surface of a silicon nitride workpiece 6 to be processed, cleaning and drying it ultrasonically with alcohol, and fixing it on an ultra-precision platform 7 superior. Start the femtosecond laser 31 by the industrial control computer 1 through the laser controller 2 to emit the laser beam to the surface of the silicon nitride workpiece 6 to complete laser focusing, turn off the femtosecond laser 31, and adjust the ultra-precision platform 7 to determine the processing area of the silicon nitride workpiece 6 . When the silicon nitride workpiece 6 is processed, the laser controller 2 is turned on by the industrial control computer 1 to select the femtosecond laser 31 in the laser generator 3 to emit a femtosecond pulse sequence, which is incident on the silicon nitride through the optical path switching module 4 and the...

Embodiment 2

[0030]An array micro-nano structure processing method of ultrafast laser combined pulse sequence, comprising the following steps: grinding and polishing the surface of the aluminum oxide workpiece 6 to be processed, ultrasonically cleaning and drying with acetone, and fixing it on an ultra-precision platform 7 . The industrial control computer 1 starts the picosecond laser 32 through the laser controller 2 to emit the laser beam to the surface of the alumina workpiece 6 to complete laser focusing, turns off the picosecond laser 32, and adjusts the ultra-precision platform 7 to determine the processing area of the alumina workpiece 6. When the alumina workpiece 6 is processed, the industrial control computer 1 turns on the laser controller 2 to select the picosecond laser 32 in the laser generator 3 to emit a picosecond pulse sequence, which is incident on the alumina workpiece 6 through the optical path switching module 4 and the focusing module 5 in sequence. surface, and s...

Embodiment 3

[0032] This embodiment provides an array micro-nano structure processing method of the same ultrafast laser combination pulse sequence as in Embodiment 1, the difference is that the pulse interval T of the femtosecond pulse sequence f1 40ns, pulse energy E f1 150μJ, laser scanning speed V 1 is 400mm / s, and the focus position is 1mm, the pulse interval T between the picosecond pulse sequence and the femtosecond pulse sequence 1 Pulse interval T of 150ns, picosecond pulse sequence p1 10ns, pulse energy E p1 100μJ, laser scanning speed V 2 is 1000mm / s, and the focus position is 0mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com