Process for synthesizing symmetric oxalate through ester exchange path

A technology of transesterification and oxalate, which is applied in the preparation of organic compounds, chemical industry, and preparation of carboxylic acid esters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

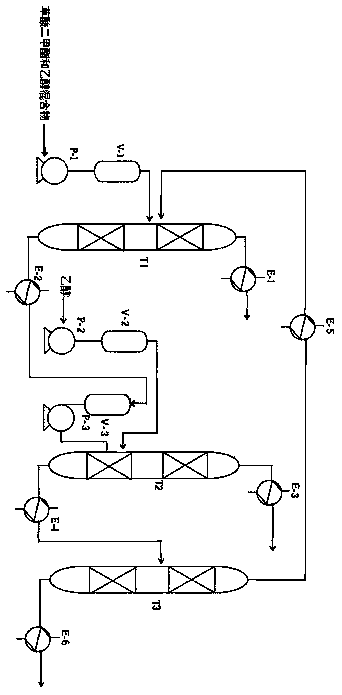

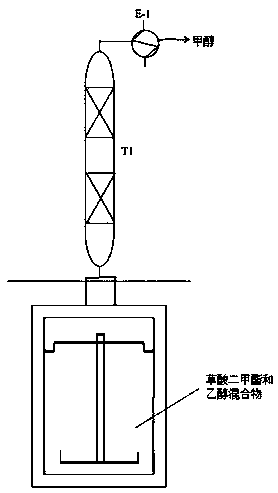

Method used

Image

Examples

Embodiment 1

[0061] Using ethanol and dimethyl oxalate as raw materials, the ratio of diethyl oxalate and methanol produced by the reaction is 1:2, and the distilled ethanol is recycled.

[0062] The catalyst is an alkaline composite material 15%CaO-5%Cr 2 o 3 -3%La 2 o 3 / Zn-meso-Y, the amount used is 3% of the total mass of raw materials, and the ratio of the cross-sectional area of the initial distillation section to the side line section is 1:1.

[0063] The operating conditions are as follows:

[0064] The first reactive distillation column T1: column diameter 1000mm; column height 19000mm; the number of plates in the public rectification section, initial distillation section, side line section, and public stripping section are 10, 20, 30, 15 respectively; the pressure in the column is 1 MPa; tower top temperature 60°C; tower bottom temperature of common stripping section 160°C; tower bottom temperature of side line section 180°C.

[0065] The second reactive distillation colum...

Embodiment 2

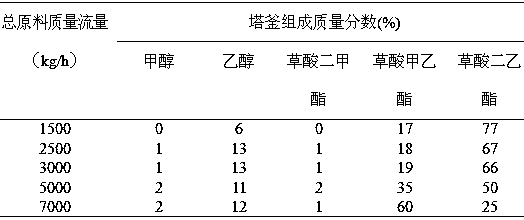

[0072] Under the operating conditions of Example 1, when the total raw material mass flow rate is 3000kg / h, the reflux ratio of the T3 vacuum distillation column is changed, and the mass fraction changes of the liquid phase components are shown in Table 2.

[0073] Table 2 The influence of different reflux ratios on the mass fraction of each liquid phase component in T3 vacuum distillation column

[0074]

[0075] As can be seen from Table 2, with the increase of reflux ratio, the mass fraction of ethanol remains basically unchanged after decreasing, and the mass fraction of diethyl oxalate remains basically unchanged after increasing. When the reflux ratio is greater than 3, each liquid The mass fraction of phase composition is almost unchanged. The reason is that after the reflux ratio reaches a certain value, the composition of the reflux of the kettle liquid has reached equilibrium. However, an excessively large reflux ratio will also reduce the processing capacity of ...

Embodiment 3

[0077] Under the operating conditions of Example 2, when the total raw material mass flow rate is 3000kg / h, the pressure of the T3 vacuum distillation column is changed, and the mass fraction changes of each liquid phase are shown in Table 3.

[0078] Table 3 The influence of different pressures on the mass fraction change of each liquid phase component in T3 vacuum distillation column

[0079]

[0080] As can be seen from Table 3, with the increase of the reaction pressure, the ethanol in each liquid phase composition remains basically unchanged after decreasing, and the mass fraction of diethyl oxalate remains basically unchanged after increasing, because the ethanol at a lower pressure The boiling point difference with diethyl oxalate increases, and ethanol and diethyl oxalate are more easily separated. However, when the pressure is higher than 3 MPa, the components remain basically unchanged. Since high pressure requires high equipment, it will greatly increase the inpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com