In-situ coating-modified bacterial cellulose hydrogel and method for preparing same

A bacterial cellulose and hydrogel technology, applied in biochemical equipment and methods, coatings, microorganism-based methods, etc., can solve problems such as difficult control, time-consuming and energy-consuming, and cumbersome processes, and achieve the effect of simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of Chitosan In-Situ Coating Modified Bacterial Cellulose Hydrogel

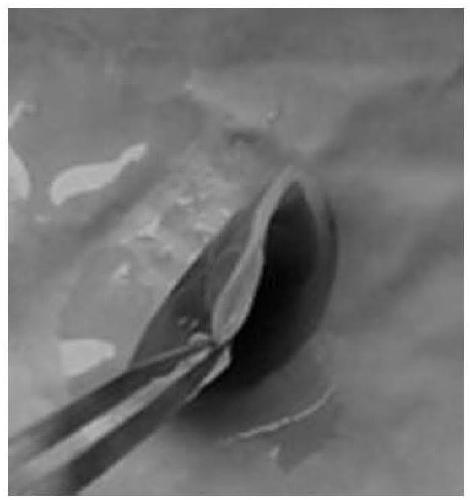

[0032] The preparation process is as image 3 shown, with the following steps:

[0033] (1) Preparation of standard HS culture solution: Weigh 4 g of glucose, 1 g of yeast powder, 0.54 g of disodium hydrogen phosphate, and 0.23 g of citric acid in ultrapure water, and prepare 200 mL of standard HS culture solution;

[0034] (2) Add 2 g of chitosan (molecular weight is about 100,000) to the standard HS culture solution, stir well, and after being dispersed and mixed, sterilize by autoclaving, and the chitosan turns brown.

[0035] (3) Inoculate 5 mL of Acetobacter xylinum (American Standard Bacteria Bank ATCC 53582) bacterium solution into the standard HS culture solution containing chitosan described in step (1), and cultivate it for 10 days in a constant temperature incubator at 30°C to obtain chitosan Sugar-coated modified bacterial cellulose hydrogel, shown as a two-layer str...

Embodiment 2

[0040] Example 2: Preparation of Chitosan In-Situ Coating Modified Bacterial Cellulose Hydrogel

[0041] Based on Example 1, the difference is: change the amount of chitosan into 4g in step (2), change the cultivation time in step (3) into 15 days, and all the other are the same as in Example 1.

Embodiment 3

[0042] Example 3: Preparation of chitosan in-situ coating modified bacterial cellulose hydrogel

[0043] Based on Example 1, the difference is: change the amount of chitosan into 6g in step (2), change the cultivation time in step (3) into 5 days, and all the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com