Preparation method for nano CuAl2/Al2O3 reinforced aluminum matrix composite material by in-situ synthesis

A technology for strengthening aluminum matrix and composite materials, which is applied in the field of metal matrix composite material preparation, and can solve problems such as reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

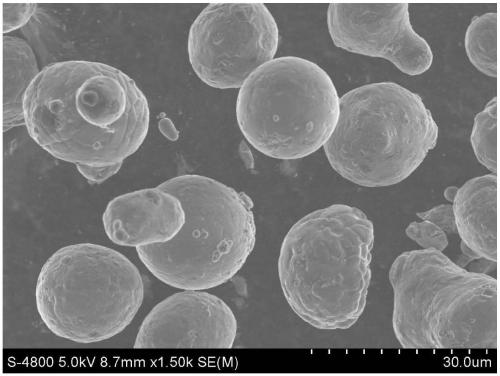

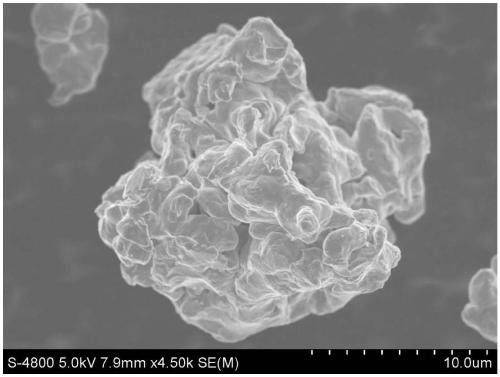

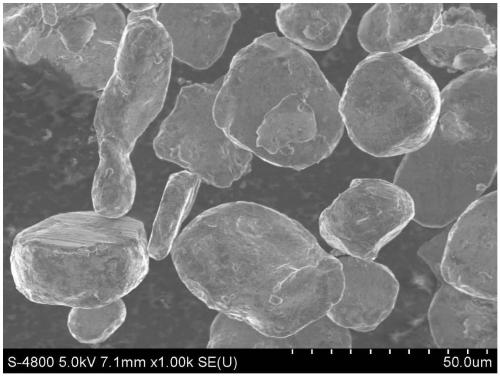

[0027] Weigh 19.8g aluminum powder (such as figure 1 shown), 0.2g copper oxide powder (as figure 2 Shown), 0.2g stearic acid (as process control agent, prevents cold welding from occurring in the ball milling process), is placed in the stainless steel ball mill jar of 250 milliliters, and fills with argon. Use a planetary ball mill to mill for 2 hours at 200r / min, with a ball-to-material ratio of 15:1. Take out the mixed powder after ball milling in the vacuum glove box (such as image 3 shown). In order to accurately measure the temperature required for hot-press sintering, firstly, the ball mill mixed powder is cold-pressed into a block, and the DSC-TG test is performed on the cold-pressed block. Then use a mold with a diameter of 45mm to carry out vacuum hot pressing sintering, the sintering temperature is 620°C, and the sintering pressure is 50MPa. Obtain nano-CuAl with a diameter of 45mm and a thickness of about 4mm 2 / Al 2 o 3 Reinforced aluminum matrix composite...

Embodiment 2

[0030] Take by weighing 19.8g aluminum powder, 0.4g copper oxide powder, 0.2g stearic acid (as process control agent, prevent cold welding from occurring in the ball milling process), be placed in the stainless steel ball mill jar of 250 milliliters, and be filled with argon. Use a planetary ball mill to mill for 2 hours at 200r / min, with a ball-to-material ratio of 15:1. The mixed powder after ball milling was taken out in a vacuum glove box, and a mold with a diameter of 45mm was used for vacuum hot pressing sintering at a sintering temperature of 620°C and a sintering pressure of 50MPa. Obtain nano-CuAl with a diameter of 45mm and a thickness of about 4mm 2 / Al 2 o 3 Reinforced aluminum matrix composite samples.

[0031] The aluminum-based composite material is processed into a pattern that can be used for stretching by wire cutting, and it is stretched by a universal tensile testing machine at a stretching rate of 0.5mm / min to obtain the tensile engineering stress-strai...

Embodiment 3

[0033] Take by weighing 19.8g aluminum powder, 0.6g copper oxide powder, 0.2g stearic acid (as process control agent, prevent cold welding from occurring in the ball milling process), be placed in the stainless steel ball mill jar of 250 milliliters, and be filled with argon. Use a planetary ball mill to mill for 2 hours at 200r / min, with a ball-to-material ratio of 15:1. The mixed powder after ball milling was taken out in a vacuum glove box, and a mold with a diameter of 45mm was used for vacuum hot pressing sintering at a sintering temperature of 620°C and a sintering pressure of 50MPa. Obtain nano-CuAl with a diameter of 45mm and a thickness of about 4mm 2 / Al 2 o 3 Reinforced aluminum matrix composite samples.

[0034] The aluminum-based composite material is processed into a pattern that can be used for stretching by wire cutting, and the tensile engineering stress-strain curve of the composite material is obtained by using a universal tensile testing machine for stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com