A preparation method of nano-silica/ferroferric oxide magnetic contrast particle reinforced biomagnesium-based composite material

A nano-silica, ferric oxide technology, applied in surgery, medical science and other directions, can solve the problems of poor targeting and positioning ability, low forming ability, etc., to improve the toughness, improve the degree of bonding, and enhance the targeting and positioning. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

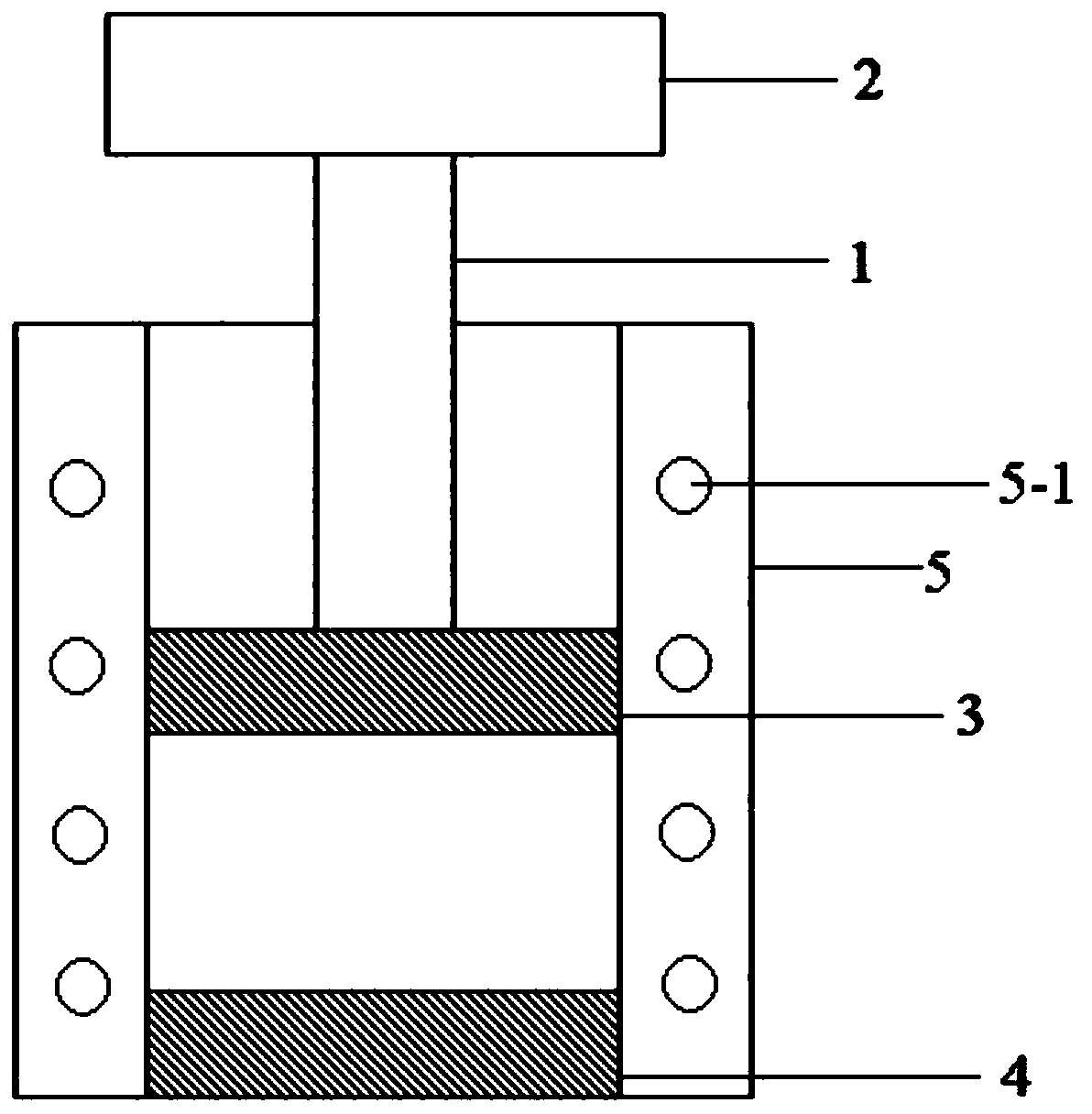

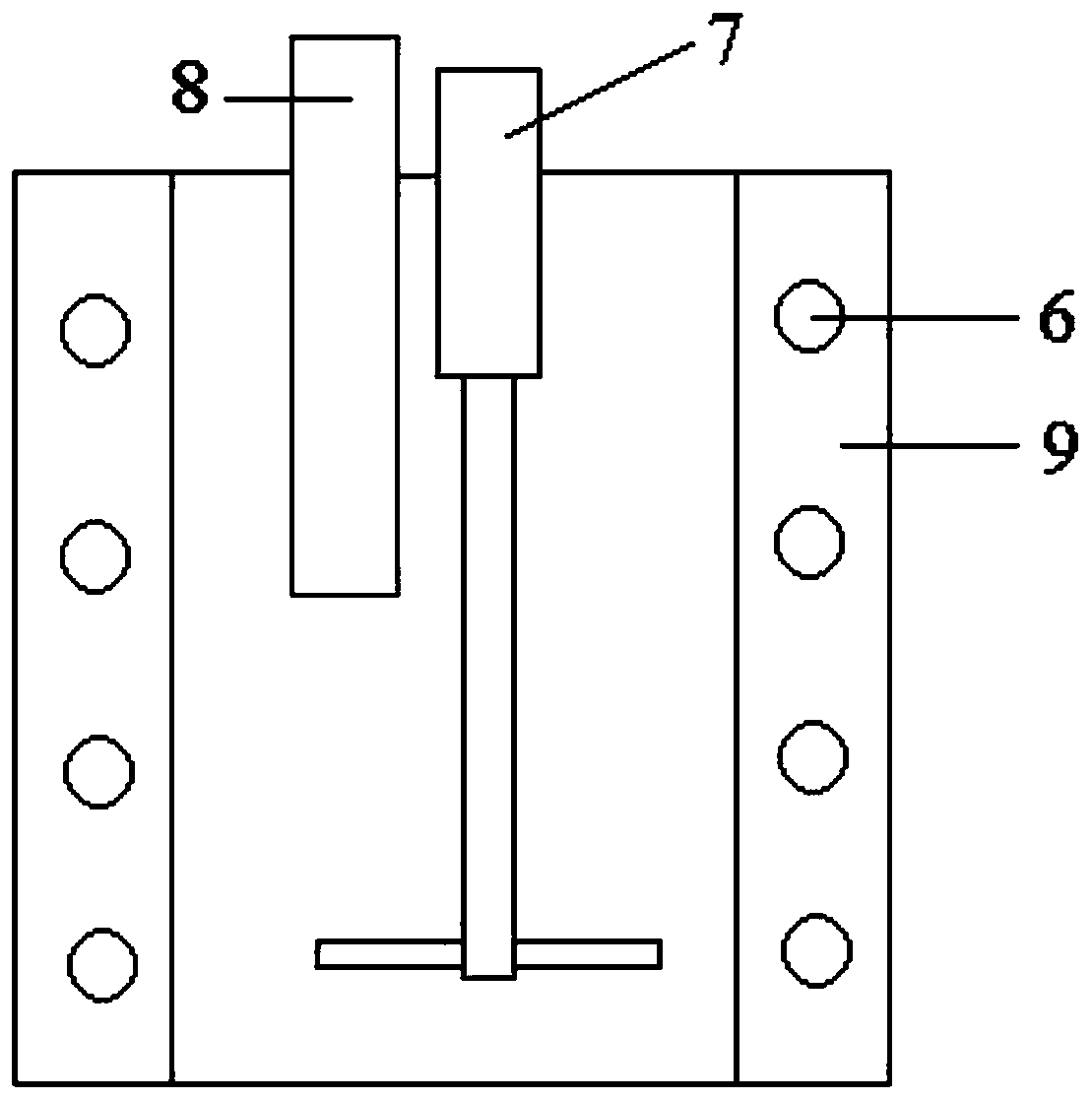

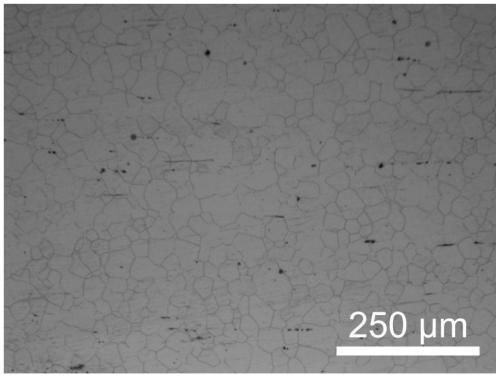

[0028] Specific implementation mode 1: This implementation mode is a preparation method of nano-silica / ferric iron tetroxide magnetic contrast particle-enhanced bio-magnesium-based composite material, which is specifically carried out according to the following steps:

[0029] 1. Preparation of nano-silica / ferroferric oxide magnetic contrast particle combination: mix nano-silica hollow microspheres with ferroferric oxide magnetic nanoparticles at a temperature of 250°C to 400°C by high-temperature ball milling, Then carry out hot pressing, and naturally cool to room temperature to obtain nano silicon dioxide / ferric oxide magnetic contrast particle combination;

[0030] The mass ratio of the nano-silica hollow microspheres to the ferroferric oxide magnetic nanoparticles is 1:(1.8~3);

[0031] The ball milling time of the high temperature ball milling is 0.5h~1.5h, and the ball milling speed is 250r / min~400r / min;

[0032] The temperature of the hot pressing is 250°C-400°C, the ...

specific Embodiment approach 2

[0040] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the particle diameter of the nano-silica hollow microspheres described in step one is 40nm~100nm, the aperture is 15nm~35nm, and the porosity is 85%~ 100%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the ferroferromagnetic nanoparticles described in step 1 is 30nm-100nm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com