Fiber-based torsion actuator with stimulative responsibility to light, heat and humidity and preparation method and application thereof

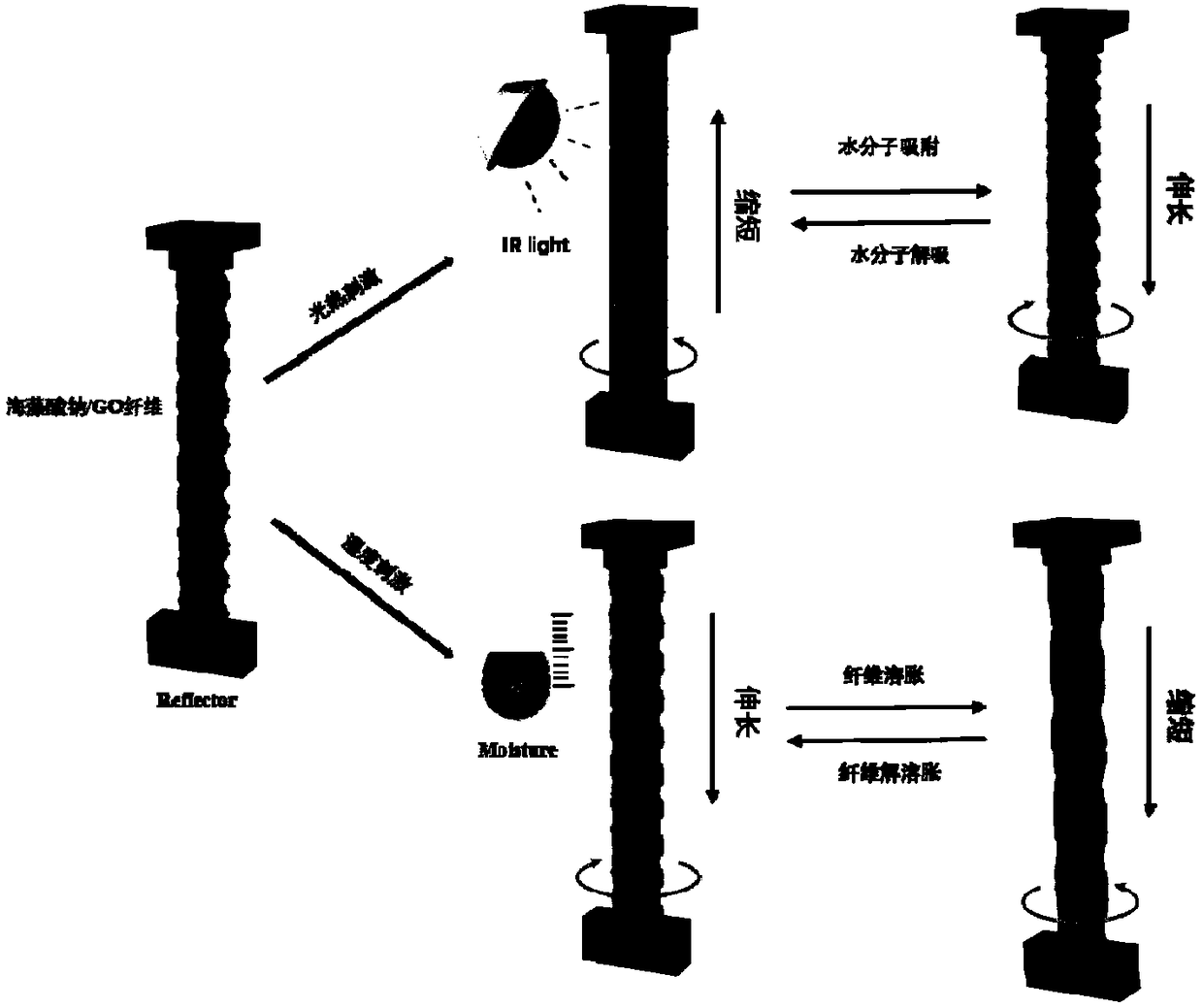

A stimuli-responsive, fiber-based technology is applied in the field of fiber-based torsional actuators and their preparation, and in the field of torsional actuators to achieve transformation and direct utilization, large-scale mass production, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

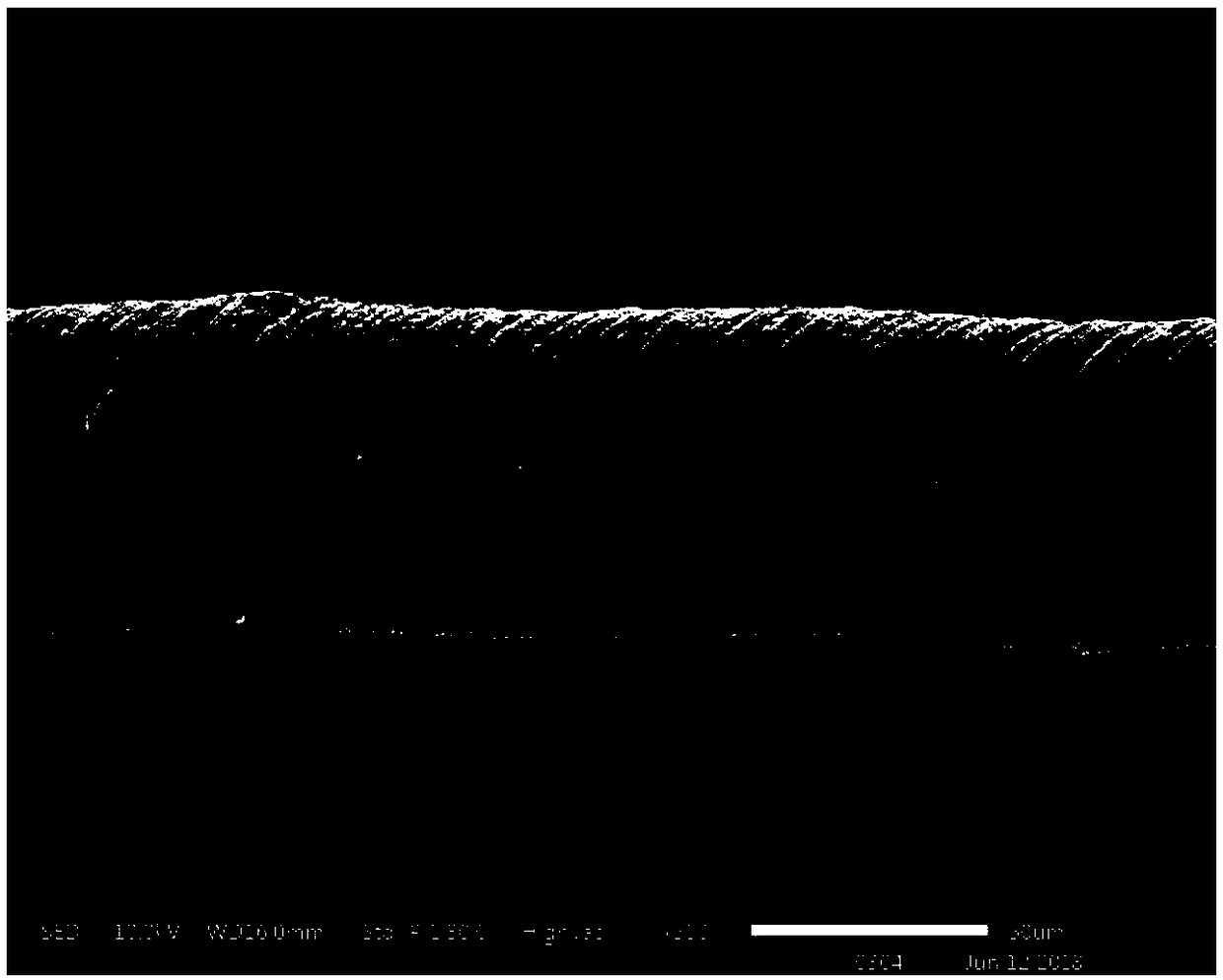

[0043] A preparation method of a fiber-based torsional actuator with stimuli responsiveness to light, heat and humidity is prepared according to the following steps:

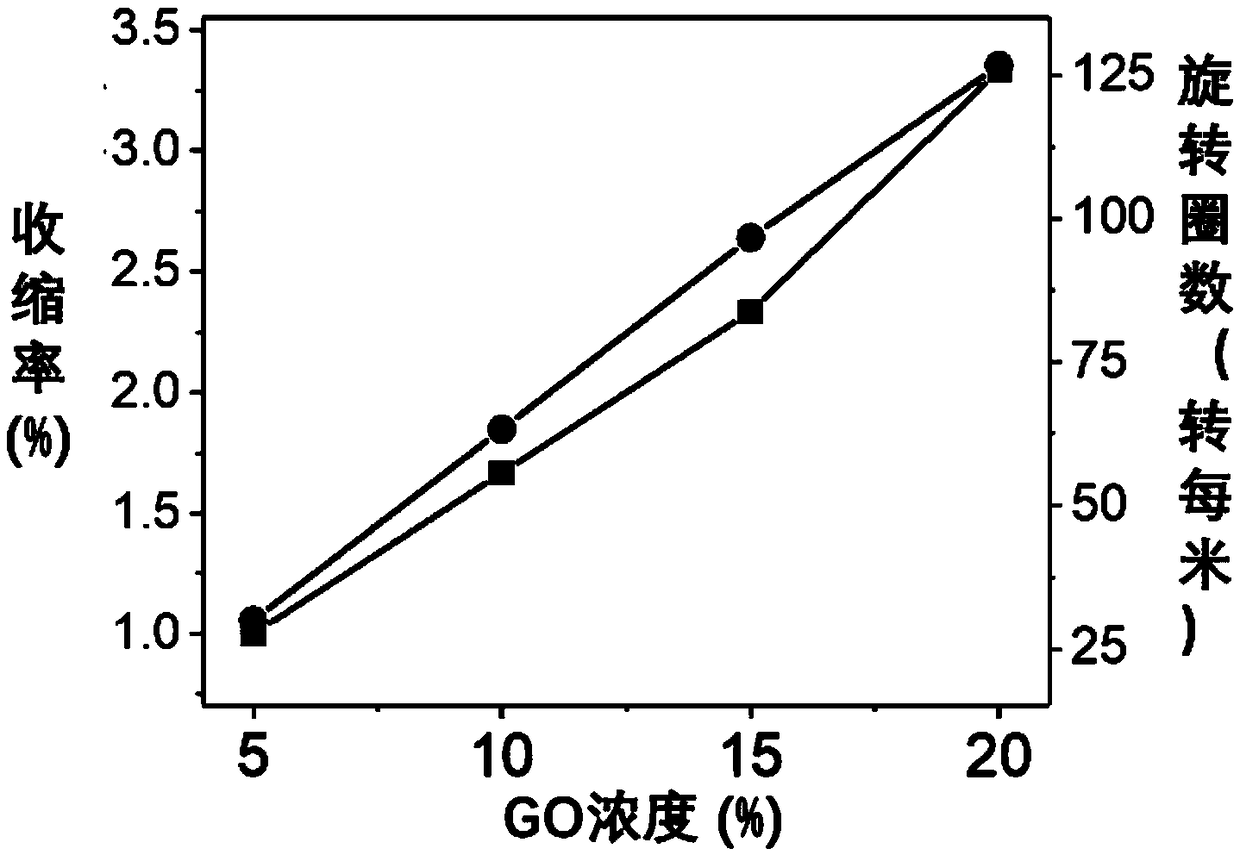

[0044] 1) Prepare sodium alginate and graphene oxide (GO) colloidal mixed spinning solution: according to the mass ratio, the mass ratio of GO and sodium alginate powder is 0.05:1, and weigh GO powder, sodium alginate powder and deionized water , GO powder was added to deionized water, ultrasonically pulverized in an ultrasonic pulverizer for 30min to obtain GO aqueous solution, sodium alginate powder was added to GO aqueous solution, the mass percentage of sodium alginate in the mixed solution was 2.5wt%, mechanically The stirring device continued to stir at room temperature for 5 hours to obtain a gel-like sodium alginate / GO colloid spinning solution, and the prepared sodium alginate / GO colloid spinning solution was left at room temperature for 24 hours to remove the air bubbles naturally ;

[0045] 2) Prepar...

Embodiment 2

[0052] A preparation method of a fiber-based torsional actuator with stimuli responsiveness to light, heat and humidity is prepared according to the following steps:

[0053] 1) Prepare sodium alginate and graphene oxide (GO) colloidal mixed spinning solution: according to the mass ratio, the mass ratio of GO to sodium alginate powder is 0.1:1, and weigh GO powder, sodium alginate powder and deionized water , GO powder was added to deionized water, ultrasonically pulverized in an ultrasonic pulverizer for 35min to obtain GO aqueous solution, sodium alginate powder was added to GO aqueous solution, the mass percentage of sodium alginate in the mixed solution was 2.5wt%; The stirring device continued to stir at room temperature for 5 hours to obtain a gel-like sodium alginate / GO colloid spinning solution, and the prepared sodium alginate / GO colloid spinning solution was left at room temperature for 24 hours to remove the air bubbles naturally ;

[0054] 2) Prepare calcium chlor...

Embodiment 3

[0060] A preparation method of a fiber-based torsional actuator with stimuli responsiveness to light, heat and humidity is prepared according to the following steps:

[0061] 1) Prepare sodium alginate and graphene oxide (GO) colloidal mixed spinning solution: according to the mass ratio, the mass ratio of GO to sodium alginate powder is 0.15:1, and weigh GO powder, sodium alginate powder and deionized water , GO powder was added to deionized water, ultrasonically pulverized in an ultrasonic pulverizer for 40min to obtain GO aqueous solution, sodium alginate powder was added to GO aqueous solution, the mass percentage of sodium alginate in the mixed solution was 2.5wt%, mechanically The stirring device continued to stir at room temperature for 5 hours to obtain a gel-like sodium alginate / GO colloid spinning solution, and the prepared sodium alginate / GO colloid spinning solution was left at room temperature for 24 hours to remove the air bubbles naturally ;

[0062] 2) Prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com