Diamond manufacturing method and manufacturing device thereof

A manufacturing method and technology of a manufacturing device, which are applied in the field of synthetic diamond manufacturing, can solve the problems of uncontrollable manufacturing process, inability to produce diamonds of shape and size, complex process, etc., so as to achieve easy realization of the overall process, controllable particle size and shape, fast growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

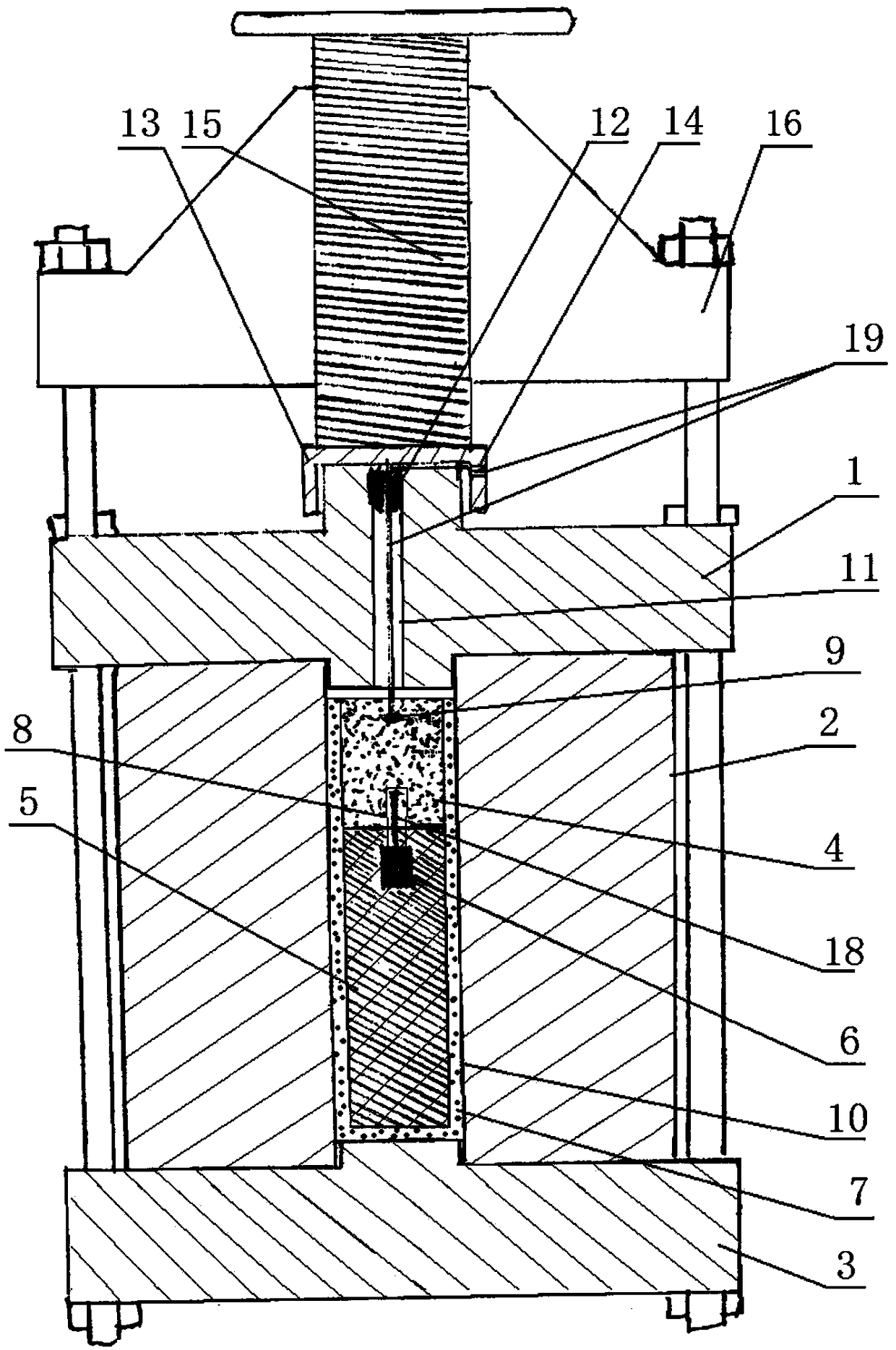

[0020] The diamond manufacturing method disclosed in this patent application is as follows: in a closed cavity, ignites the smokeless powder filled therein, and triggers a thermite reaction to form a high temperature and high pressure in which graphite crystals are directly transformed into diamonds. Wherein, the purity of the graphite crystal itself determines the purity of the diamond. If high-purity diamond is to be manufactured, the graphite crystal can be selected from high-purity graphite, such as quasi-single crystal graphite or polycrystalline graphite.

[0021] The patent application also provides a diamond manufacturing device for realizing the diamond manufacturing method. The diamond manufacturing device is an autoclave with a slender cylindrical cavity 10, and the heating wire 9 in the cavity 10 is insulated from the autoclave by an electric connecting wire 19 and leads out of the autoclave. The height of the cavity is preferably at least 4 times its diameter.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com