Nanoparticle composite high-temperature guar gum fracturing fluid

A technology of nano-particles and fracturing fluids, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as difficulty in large-scale promotion, and achieve the effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Nanoparticle SiO 2 Or the surface modification process of ZnO is as follows: in 50ml ethanol solution, add 11g of 3-aminopropyltriethoxysilane, then add 6g into nanoparticles, react for 40min, add 0.02g sodium lauryl sulfate and 5 g of acrylic monomer, initiated with 0.01 g of ammonium persulfate.

[0023] Add 30kg of water into the reaction tank, and slowly inhale 0.02kg of surface-modified SiO 2 Particles, slowly inhale 0.3kg hydroxypropyl guar gum, disperse evenly, add 0.4g choline chloride; add 0.4kg surfactant, and 0.1kg sodium thiosulfate. Add 68.78 kg of water, and then stir at room temperature for 30 minutes to obtain the nanocomposite guar gum fracturing fluid base fluid. Before construction, add triethanolamine boron complex in the stirring tank according to the ratio of 100:0.3.

Embodiment 2

[0025] Add 30kg of water into the reaction tank, slowly inhale 0.04kg of surface-modified ZnO particles, then slowly inhale 0.5kg of carboxymethylhydroxypropyl guar gum, and add 0.5g of NH 4 Cl; add 0.3kg surfactant and 0.2kg sodium thiosulfate. Add 68.46 kg of water, and then stir at room temperature for 30 minutes to obtain the nanocomposite guar gum fracturing fluid base fluid. Before construction, add triethanolamine boron complex in the stirring tank according to the ratio of 100:0.5.

Embodiment 3

[0027] Add 50kg of water in the reaction tank, slowly inhale 0.06kg of surface-modified ZnO particles, then slowly inhale 0.6kg of hydroxypropyl guar gum, and add 0.4g of choline chloride after the dispersion is uniform; add 0.5kg of surfactant and 0.3 kg sodium thiosulfate. Add 48.14 kg of water, and then stir at room temperature for 30 minutes to obtain the nanocomposite guar gum fracturing fluid base fluid. Before construction, add triethanolamine boron complex in the mixing tank according to the ratio of 100:0.6.

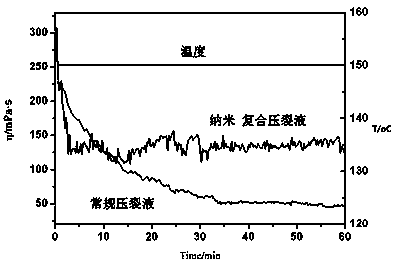

[0028] From figure 1 It can be seen from the figure that under the same formulation conditions, the viscosity of the fracturing fluid without nanoparticles decreases to 50mpa.s after shearing at 150°C for 30 minutes, which cannot meet the construction requirements. However, after adding nanoparticles, the viscosity has been maintained at 120mpa.s, which can fully meet the needs of construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com