A method for producing annealing-free vanadium-containing heat-resistant steel hot-rolled wire rod

A technology of hot-rolled wire rod and heat-resistant steel, which is applied in the field of metallurgy to achieve good high-temperature durable strength, maintain high-temperature durable strength, and reduce the effect of segregation of alloy elements in billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

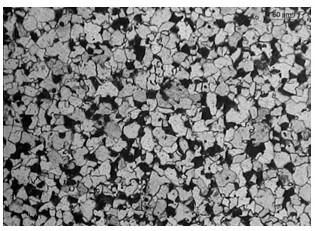

[0037] In this embodiment, the specification of annealing-free vanadium-containing heat-resistant steel hot-rolled wire rod is φ5.5mm, and its production method comprises the following steps:

[0038] (1) Through primary smelting in converter, LF refining, RH refining, and continuous casting process, a rectangular steel slab is made. The size of the end surface of the slab is 325mm*280mm. The chemical composition and mass percentage of the casting slab are: C: 0.11%, Si : 0.25%, Mn: 0.58%, P: 0.012%, S: 0.006%, Cr: 1.15%, Mo: 0.30%, and the rest are iron and unavoidable impurity elements; double slag smelting is used for the initial smelting of the converter, and the end point P is controlled : 0.005%; continuous casting adopts low superheat and dynamic soft reduction control process, superheat is 20°C, constant casting speed is 0.6m / min, inlet reduction rate is 0.512mm / m under soft reduction, and outlet reduction rate is 0.179 mm / m, slab center segregation is controlled at le...

Embodiment 2

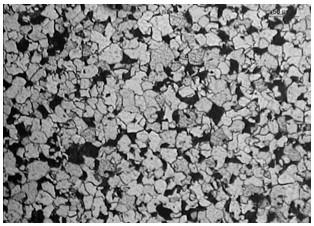

[0048] In this embodiment, the annealing-free vanadium-containing heat-resistant steel hot-rolled wire rod specification is φ6.5mm, and its production method comprises the following steps:

[0049] (1) After preliminary smelting in converter, LF refining, RH refining, and continuous casting process, a rectangular steel slab is made. The size of the end face of the slab is 325mm*280mm. The chemical composition and mass percentage of the casting slab are: C: 0.12%, Si : 0.23%, Mn: 0.52%, P: 0.010%, S: 0.005%, Cr: 1.13%, Mo: 0.29%, and the rest are iron and unavoidable impurity elements; double slag smelting is used for the primary smelting of the converter, and the endpoint P is controlled : 0.006%; continuous casting adopts low superheat and dynamic soft reduction control technology, superheat is 30 ℃, constant casting speed is 0.6m / min, inlet reduction rate is 0.523mm / m under soft reduction, and outlet reduction rate is 0.186 mm / m, slab center segregation is controlled at leve...

Embodiment 3

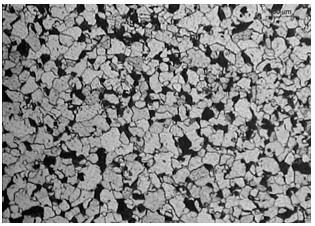

[0059] In this embodiment, the annealing-free vanadium-containing heat-resistant steel hot-rolled wire rod specification is φ8.0mm, and its production method comprises the following steps:

[0060] (1) After preliminary smelting in converter, LF refining, RH refining, and continuous casting process, a rectangular steel slab is made. The size of the end face of the slab is 325mm*280mm. The chemical composition and mass percentage of the casting slab are: C: 0.12%, Si : 0.24%, Mn: 0.55%, P: 0.011%, S: 0.003%, Cr: 1.12%, Mo: 0.32%, and the rest are iron and unavoidable impurity elements; double slag smelting is used for the initial smelting of the converter, and the end point P is controlled : 0.007%; continuous casting adopts low superheat and dynamic soft reduction control process, superheat is 28 ℃, constant casting speed is 0.6m / min, inlet reduction rate is 0.527mm / m under soft reduction, and outlet reduction rate is 0.188 mm / m, slab center segregation is controlled at level ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com