High-flexibility intelligent production line design method

A design method and highly flexible technology, applied in the field of automation, can solve problems such as small scope of application, multiple clamping of equipment, and low processing accuracy, and achieve the effects of ensuring structural compatibility, strong scalability, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

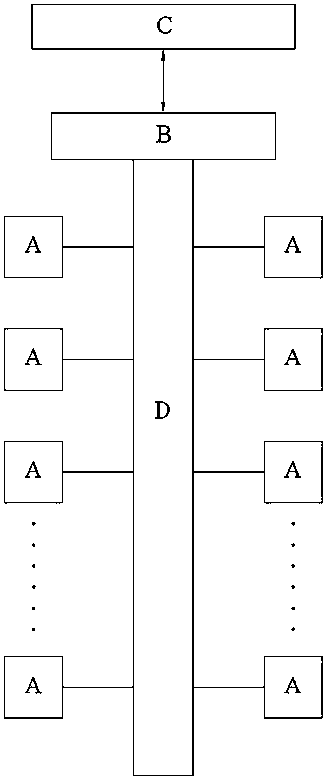

[0017] Such as figure 1 Shown, the inventive method comprises the following steps:

[0018] (1) Workstation A setting: establish all workstations including automatic product assembly and testing procedures, set up a unified docking interface and define compatible interface protocols for each workstation, and set up a data acquisition device on each workstation. The automatic assembly and testing process of the product includes but is not limited to automatic loading, automatic assembly, automatic dispensing, automatic screwing, automatic optical testing, ICT / FCT testing, defect detection, air tightness testing and / or automatic blanking. The automatic optical testing process includes wavelength l, power w, radiation angle θ, light intensity q, number of bright / dark spots n, current I, voltage V, temperature T, optical distance accuracy d, mechanical positioning accuracy tolerance t, camera and The optical center alignment deviation e of the product or the combination of optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com