A lithium-supplemented electrode of a negative electrode of a lithium ion battery and a preparation method thereo

An electrode and negative electrode technology, applied in the field of lithium ion battery negative electrode supplementary lithium electrode and its preparation, can solve the problems of poor processing performance and safety performance of the pole piece, and achieve the effects of reducing battery processing difficulty, reducing danger, and reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

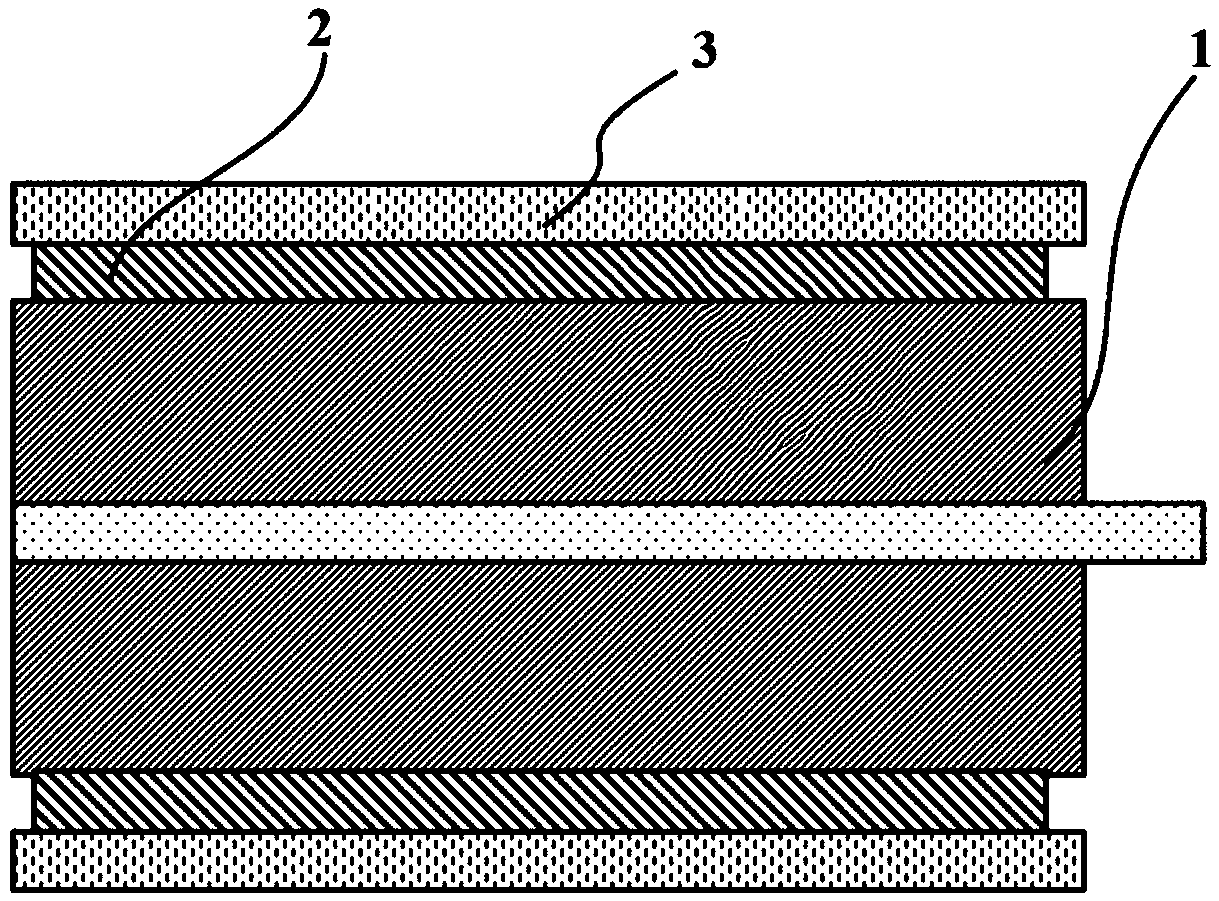

Image

Examples

Embodiment 1

[0035] The specific preparation steps of the negative lithium-replenishing electrode in this embodiment are as follows:

[0036] (1) Use the fixture of the vapor deposition instrument to fix the prepared silicon-based negative electrode sheet, place it on the top of the deposition instrument, use pure lithium lithium ribbon as the evaporation lithium source, perform vapor deposition at 600 °C, and fill it with Ar gas. After cooling down, the pole piece is taken out to obtain a pre-lithium electrode;

[0037] (2) Add 200g of lithium bisoxalate borate into 600g of acetone solvent, and stir it mechanically for 6 hours to make a coating solution for later use;

[0038] (3) Use an extrusion coater to coat in the drying room, adjust the coating thickness, apply the coating solution to one side of the deposited pre-lithium electrode, and place it at 80°C for vacuum drying. The pre-lithium electrode Repeat the above coating and drying process on the other side to obtain an organic th...

Embodiment 2

[0040] The specific preparation steps of the negative lithium-replenishing electrode in this embodiment are as follows:

[0041] (1) Add passivated lithium powder directly into the slurry to prepare a tin-based negative electrode slurry by direct mixing method, and then coat it to prepare a pre-lithium electrode;

[0042] (2) Add 150g of lithium difluorooxalate and 50g of lithium difluorosulfonyl imide into 400g of diethyl carbonate solvent, and stir it mechanically for 5 hours to make a coating solution for later use;

[0043] (3) Use an extrusion coater in the drying room for coating, adjust the coating thickness, apply the coating solution to one side of the pre-lithium electrode, and place it at 45°C for vacuum drying, and the other side of the pre-lithium electrode The above coating and drying process was repeated to obtain a negative lithium-replenishing electrode with an organic film layer thickness of 1 μm.

Embodiment 3

[0045] The specific preparation steps of the negative lithium-replenishing electrode in this embodiment are as follows:

[0046] (1) Using the electrochemical pre-lithium method, directly connect the pure lithium-lithium strip to the prepared graphite negative electrode sheet and place it in the lithium salt solution to prepare the pre-lithium electrode;

[0047] (2) Add 100g of lithium tetrafluoroborate and 50g of lithium difluorooxalate into 500g of ethylene carbonate solvent, and use mechanical stirring for 6 hours to make a coating solution for later use;

[0048] (3) Use an extrusion coater to coat in the drying room, adjust the coating thickness, apply the coating solution to one side of the pre-lithium electrode, and place it at 120°C for vacuum drying, and the other side of the pre-lithium electrode The above coating and drying process was repeated to obtain a negative lithium-replenishing electrode with an organic thin film layer thickness of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com