Anti-aging black ginger extract and preparation method thereof

An extract and anti-aging technology, which is applied in the direction of food ingredients containing natural extracts, food extraction, food ingredients containing organic compounds, etc., can solve the problems of complex oil components, shorten the extraction time, accelerate the breaking of the wall, and improve the solubility and the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

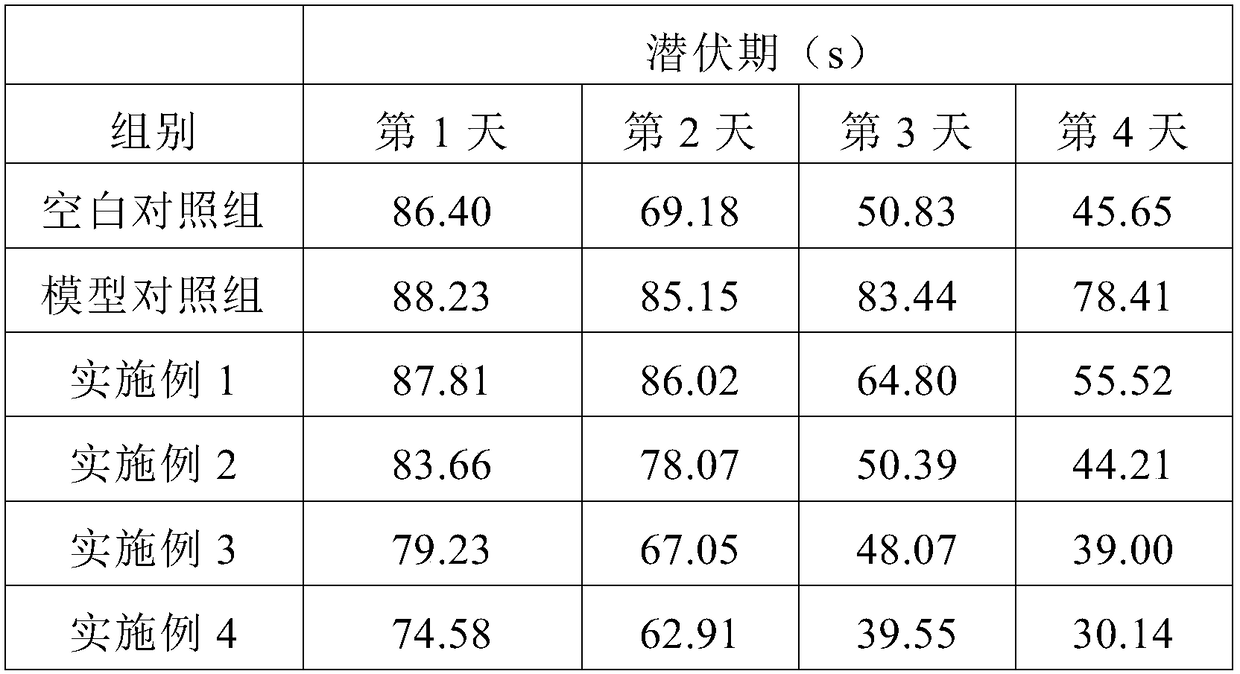

Embodiment 1

[0042] The preparation method of anti-aging black ginger extract comprises the following steps:

[0043] Step 1: Using black ginger rhizomes as raw materials, put the black ginger rhizomes in liquid nitrogen and keep them frozen for 10 minutes; take out the frozen black ginger rhizomes, crush them into powder with a powder machine, and pass through an 80-mesh sieve to obtain black ginger powder ;

[0044] Step 2: Weigh black ginger powder, add ethyl acetate according to the ratio of solid to liquid 1:10 (g / mL), reflux and extract at 90°C for 8 hours, collect the extract; add an equal volume of water to the extract and extract for 1 hour , separate the ethyl acetate phase of the upper layer and the water phase of the lower layer; dry the ethyl acetate phase of the upper layer under reduced pressure at 50° C. and an absolute pressure of 0.03 MPa to remove ethyl acetate, and then vacuum freeze-dry to obtain the anti-aging Black Ginger Extract.

Embodiment 2

[0046] The preparation method of anti-aging black ginger extract comprises the following steps:

[0047] Step 1: Using black ginger rhizomes as raw materials, put the black ginger rhizomes in liquid nitrogen and keep them frozen for 10 minutes; take out the frozen black ginger rhizomes, crush them into powder with a powder machine, and pass through an 80-mesh sieve to obtain black ginger powder ;

[0048] Step 2: Weigh black ginger powder, add 1-n-decylpyridine bromide aqueous solution with a molar concentration of 1mol / L according to the ratio of solid to liquid 1:130 (g / mL), and microwave under the conditions of microwave power 400W and temperature 50°C Extract for 5 minutes, then cool down to 26°C naturally, and collect the microwave extract;

[0049] Step 3: Vacuum freeze-dry the microwave extract to obtain a microwave extract concentrate; separate the microwave extract concentrate by column chromatography, use silica gel as the column filler, and the weight ratio of the ...

Embodiment 3

[0051] The preparation method of anti-aging black ginger extract comprises the following steps:

[0052] Step 1: Using black ginger rhizomes as raw materials, put the black ginger rhizomes in liquid nitrogen and keep them frozen for 10 minutes; take out the frozen black ginger rhizomes, crush them into powder with a powder machine, and pass through an 80-mesh sieve to obtain black ginger powder ;

[0053] Step 2: Weigh black ginger powder, add 1-n-decylpyridine bromide aqueous solution with a molar concentration of 1mol / L according to the ratio of solid to liquid 1:130 (g / mL), and microwave under the conditions of microwave power 400W and temperature 50°C Extract for 5 minutes, then cool down to 26°C naturally, and collect the microwave extract;

[0054] Step 3: Vacuum freeze-dry the microwave extract to obtain a microwave extract concentrate; separate the microwave extract concentrate by column chromatography, use silica gel as the column filler, and the weight ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com