Red mud adsorbent and preparation method and application thereof

A technology for adsorbent and red mud, applied in the field of red mud adsorbent and its preparation, can solve the problems of high requirements for preparation conditions, high cost of adsorption process, increased cost of adsorption process of polluting elements in water, etc., and achieves the effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

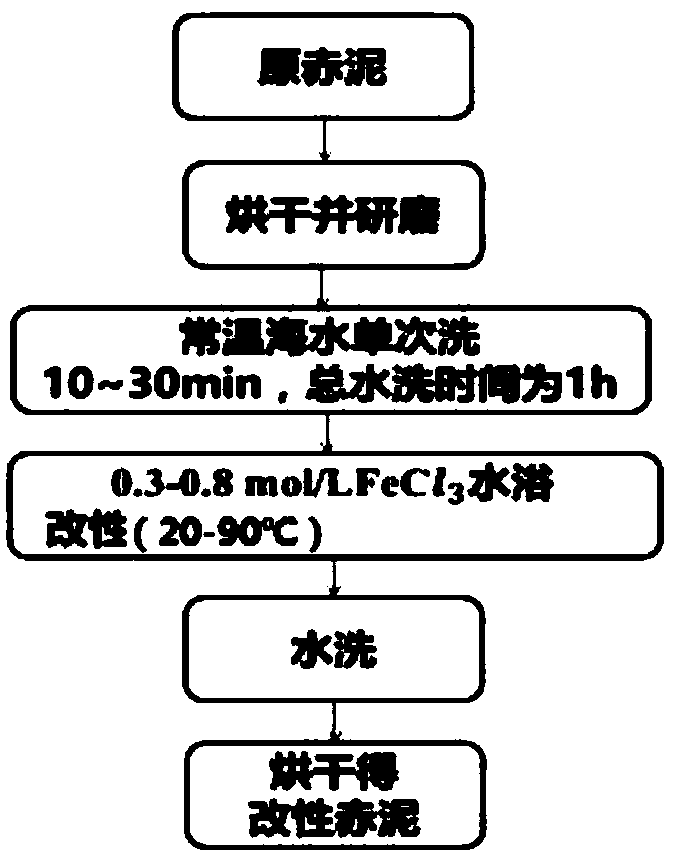

[0027] The invention provides a kind of preparation method of red mud adsorbent, comprises the following steps:

[0028] (1) Using seawater to wash and modify the red mud to obtain seawater modified red mud;

[0029] (2) Mix the seawater modified red mud obtained in the step (1) with ferric chloride solution, and heat and modify the obtained mixed solution to obtain the red mud adsorbent.

[0030] The invention uses seawater to wash and modify the red mud to obtain seawater modified red mud. In the present invention, the seawater preferably includes the following concentration of cations: Ca 2+ 350~650ppm, K + 300~700ppm, Li + 0.03~0.19ppm, Mg 2+ 630~1400ppm, Na + 10000~40000ppm and Sr 2+ 6-10ppm; TP (that is, the total content of organic phosphorus, phosphate and phosphite) in the seawater is preferably 0.06-0.14ppm; the anions contained in the seawater preferably include HCO 3 - and Br - ; The present invention has no special requirements on the content of anions in...

Embodiment 1

[0051] Weighed 10g of alkaline waste residue red mud (abbreviated as RMA, as shown in Table 1) produced by a Bayer aluminum smelting enterprise and crushed it into 60 meshes. Prepare seawater and wash it at 25°C with 250mL of seawater each time. The time for a single seawater wash is half an hour. After the seawater wash is completed, wash with clean water and centrifuge to obtain seawater modified red mud. Then divide the seawater modified red mud into two parts and add 0.5mol / L ferric chloride solution until the pH is 4.0, and react under water bath and stirring conditions at 25°C and 90°C respectively until the pH value of the mixed solution is stable at 4. ~5, and then centrifuged, washed with water and dried in sequence to obtain the red mud adsorbent.

[0052] The red mud adsorbent obtained by reaction at 25°C is represented by RMA-25°C; the red mud adsorbent obtained by reaction at 90°C is represented by RMA-90°C.

[0053] The chemical composition of the alkaline waste...

Embodiment 2

[0061] The alkaline waste residue red mud (abbreviated as RMB, and the specific element composition is shown in Table 1) produced by an aluminum smelting enterprise using the Bayer process was weighed, and other conditions were the same as in Example 1. The red mud adsorbent obtained by reacting at 25°C is represented by RMB-25°C; the red mud adsorbent obtained by reacting at 90°C is represented by RMB-90°C.

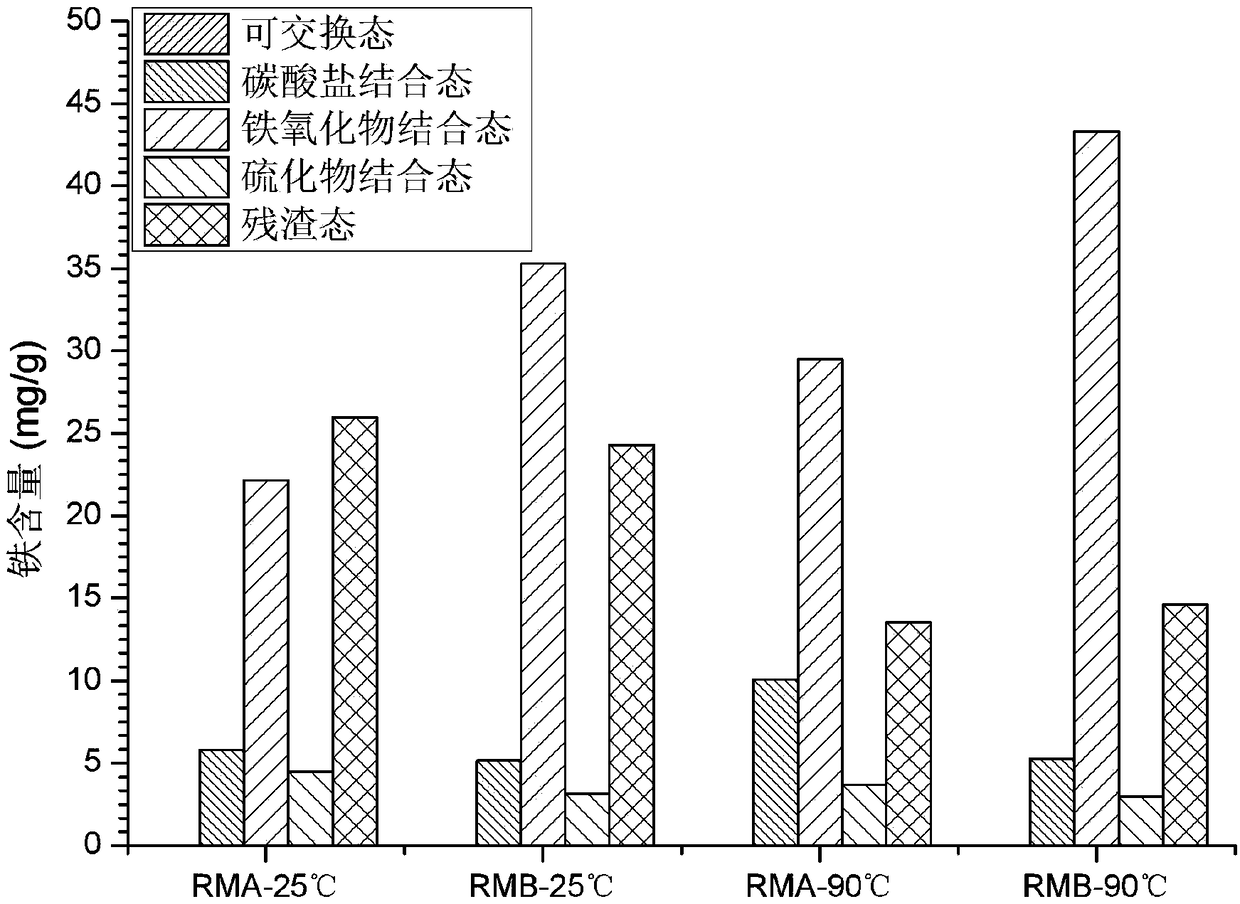

[0062] The obtained red mud is continuously leached, and the obtained results are as follows: figure 2 And as shown in Table 2.

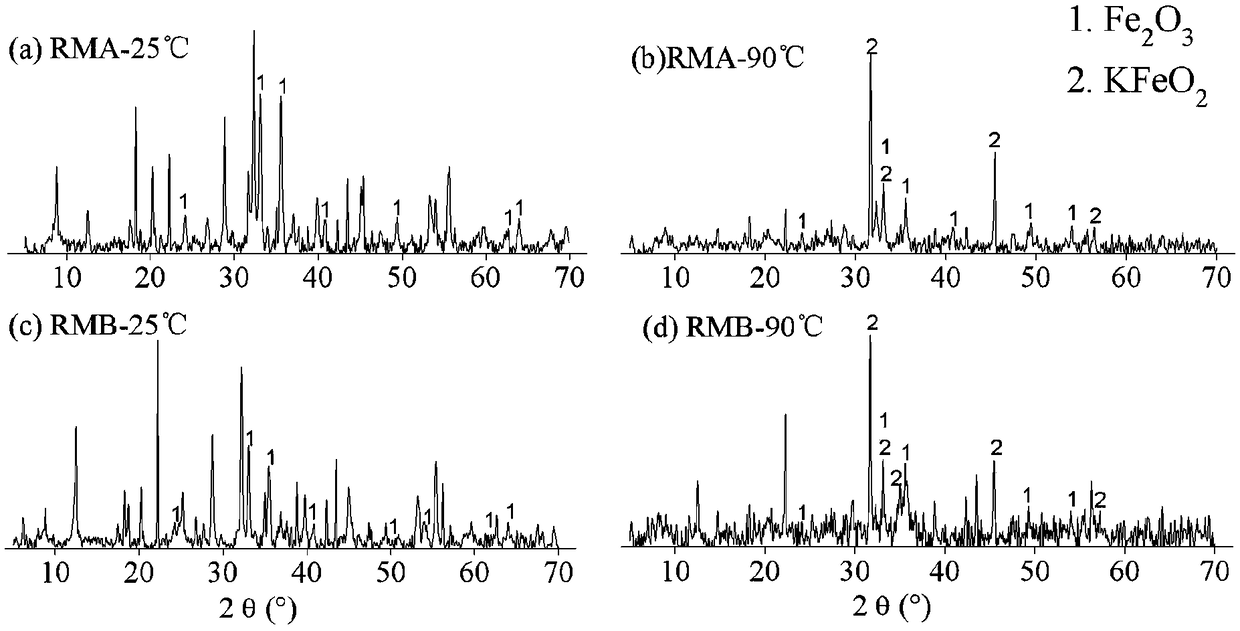

[0063] The red mud adsorbent obtained in this embodiment and the raw red mud are subjected to X-ray diffraction analysis, such as image 3 and Figure 5 As shown, the same conclusion as in Example 1 can be obtained.

[0064] In order to verify the effect of seawater adsorption modification, XRD analysis was carried out on the red mud raw materials of Example 1 and Example 2 and the red mud after seawater washing and modification respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com