Preparation method of magnetically separable bismuth tungstate composite

A composite material, bismuth tungstate technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve insufficient light utilization, catalyst quantum efficiency Low cost, difficult photocatalyst recovery and reuse, etc., to avoid secondary pollution and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

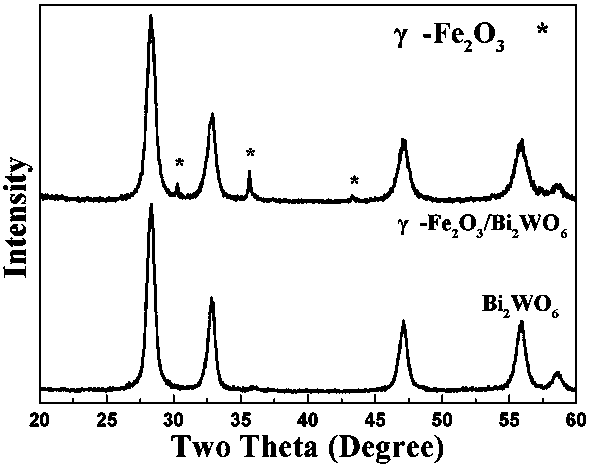

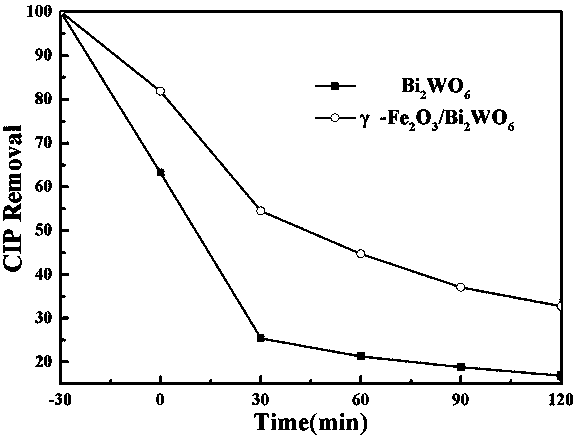

specific Embodiment approach 1

[0013] The specific embodiment one: one, take a certain amount of iron acetylacetonate (C 15 h 21 FeO 6 ) was dissolved in ethanol (the molar ratio to iron acetylacetonate was 1000:1), and after fully stirring for 60 minutes, it was placed in a polytetrafluoroethylene-lined reactor and reacted at 180°C for 15 hours. After magnetic separation and ethanol cleaning, tetraoxide was obtained. Three iron nanoparticles; 2. Dissolve a certain amount of sodium tungstate and bismuth nitrate (the atomic ratio of bismuth and tungsten is 2:1) in a certain amount of ethylene glycol (the molar ratio of metal to metal is 100:1), and stir well for 1 , slowly drop sodium tungstate solution into bismuth nitrate ethylene glycol solution, stir and mix for 2 hours, move the mixed solution to a polytetrafluoroethylene-lined reaction kettle, and perform solvothermal reaction at 180°C for 15 hours, ethanol and deionized water After fully washing, calcined at 300°C for 3 hours to obtain bismuth tungs...

specific Embodiment approach 2

[0014] Specific embodiment two: one, take a certain amount of iron acetylacetonate (C 15 h 21 FeO 6 ) dissolved in ethanol (the molar ratio to iron acetylacetonate is 500:1), fully stirred for 30 minutes, placed in a polytetrafluoroethylene-lined reactor and reacted at 150 ° C for 20 hours, magnetically separated and washed with ethanol to obtain tetraoxide Three iron nanoparticles; 2. Dissolve a certain amount of sodium tungstate and bismuth nitrate (the atomic ratio of bismuth and tungsten is 2:1) in a certain amount of ethylene glycol (the molar ratio of the metal to the metal is 50:1), and stir thoroughly for 1 , slowly drop sodium tungstate solution into bismuth nitrate ethylene glycol solution, stir and mix for 1h, move the mixed solution to a polytetrafluoroethylene-lined reaction kettle, and conduct solvothermal reaction at 140°C for 20h, ethanol and deionized water After fully washing, calcined at 300°C for 3 hours to obtain bismuth tungstate nanoparticles; 3. Weigh...

specific Embodiment approach 3

[0015] Specific embodiment three: one, take by weighing a certain amount of iron acetylacetonate (C 15 h 21 FeO 6 ) was dissolved in ethanol (the molar ratio to iron acetylacetonate was 1000:1), and after fully stirring for 60 minutes, it was placed in a polytetrafluoroethylene-lined reactor and reacted at 200°C for 10 hours. After magnetic separation and ethanol cleaning, tetraoxide was obtained. Three iron nanoparticles; 2. Dissolve a certain amount of sodium tungstate and bismuth nitrate (the atomic ratio of bismuth and tungsten is 2:1) in a certain amount of ethylene glycol (the molar ratio of metal to metal is 100:1), and stir well for 1 , slowly drop sodium tungstate solution into bismuth nitrate ethylene glycol solution, stir and mix for 2 hours, move the mixed solution to a polytetrafluoroethylene-lined reactor, and conduct solvothermal reaction at 200°C for 5 hours, ethanol and deionized water After fully washing, calcined at 300°C for 5 hours to obtain bismuth tung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com