Nitrogen and phosphorus removal material and preparation method thereof

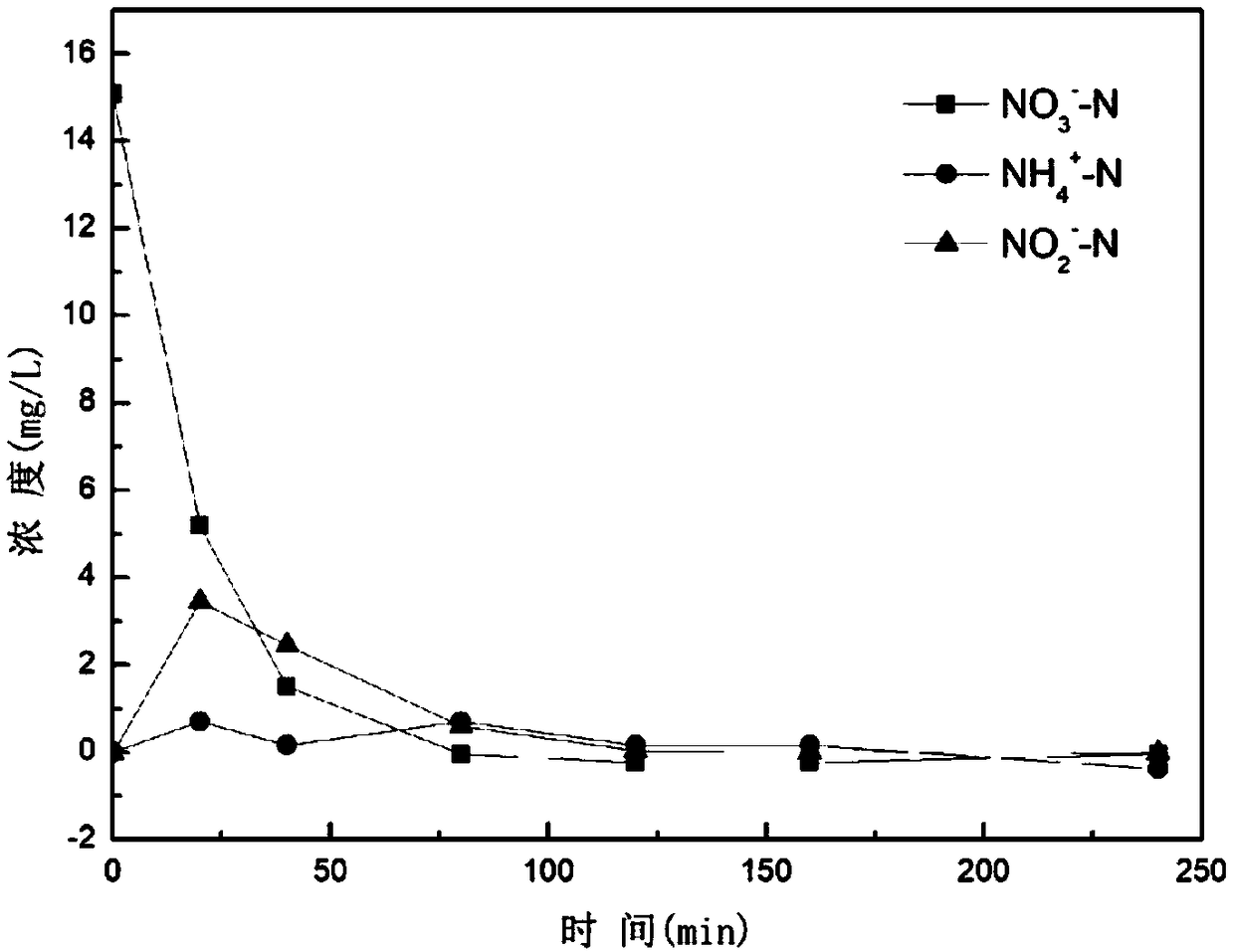

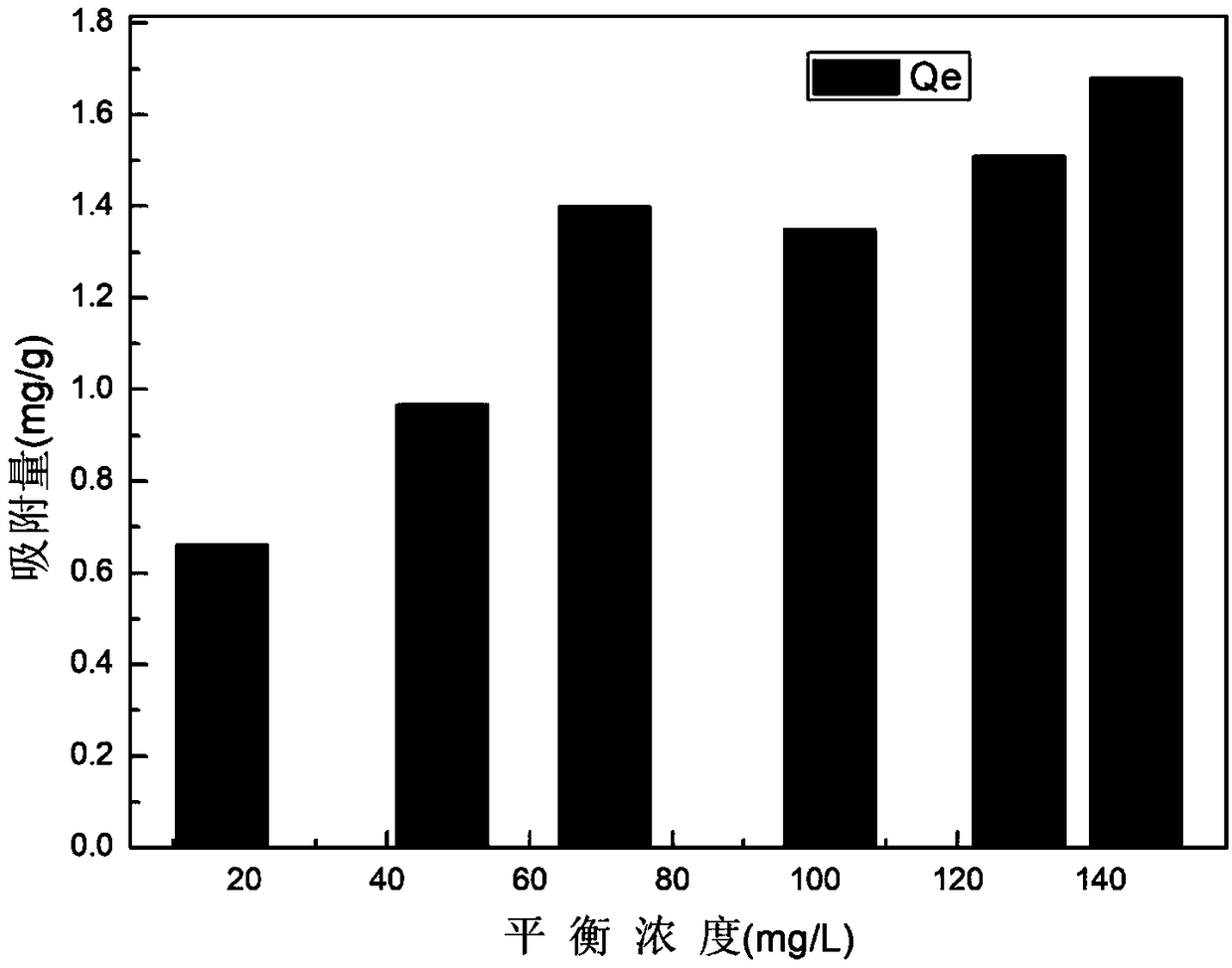

A technology for nitrogen and phosphorus removal and phosphorus removal agent, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as limited capacity, and achieve strong selection ability and continuous recycling effect Good, good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Example 1 Nitrogen and Phosphorus Removal Material

[0031] According to the mass ratio: reduced iron powder: activated carbon powder: bentonite: copper powder: roasted Mg-Al hydrotalcite: PEG-200 is 40.25: 12.75: 25: 2: 10: 10 Weigh raw materials (can be weighed in g or kg Take), mix iron powder, activated carbon powder, bentonite, copper powder and hydrotalcite-like evenly. Dilute PEG-200 in a small amount of deionized water to reduce the viscosity, and add it to the evenly mixed iron powder and other raw materials. Add an appropriate amount of deionized water and stir until it is suitable for granulation, and prepare granules with a particle diameter of 8 mm. The prepared granules were dried in a vacuum oven at 105° C. for 2 h. Then put the material into a vacuum tube furnace, under the environment of nitrogen as a protective gas, first keep it at 300°C for 30 minutes, then raise the temperature to 1000°C and keep it for 120 minutes, and finally cool...

Embodiment 2

[0033] Preparation of Example 2 Nitrogen and Phosphorus Removal Materials

[0034] According to the mass ratio: reduced iron powder: activated carbon powder: bentonite: copper powder: roasted state Zn-Fe hydrotalcite: PEG-300 is 31.25: 13.75: 23: 2: 10: 20 Weigh raw materials (can be weighed in g or kg Take), mix iron powder, activated carbon powder, bentonite, copper powder and hydrotalcite-like, dilute PEG-300 in a small amount of deionized water to reduce the viscosity, and add it to the evenly mixed iron powder and other raw materials. Add an appropriate amount of deionized water and stir until it is suitable for granulation, and prepare granules with a particle diameter of 4 mm. The prepared granules were dried in a vacuum oven at 105° C. for 1 h. Then put the material into a vacuum tube furnace, under the environment of nitrogen as a protective gas, first keep it at 400°C for 30 minutes, then raise the temperature to 1100°C and keep it for 120 minutes, and finally cool ...

Embodiment 3

[0036] Preparation of Example 3 Nitrogen and Phosphorus Removal Materials

[0037] According to the mass ratio: reduced iron powder: activated carbon powder: bentonite: indium powder: roasted Ni-Fe hydrotalcite: PEG-400 is 45:20:20:2:8:5 Weigh raw materials (can be weighed in g or kg Take), mix iron powder, activated carbon powder, bentonite, indium powder and hydrotalcite-like, dilute PEG-400 in a small amount of deionized water to reduce the viscosity, and add it to the evenly mixed iron powder and other raw materials. Add an appropriate amount of deionized water and stir until it is suitable for granulation, and prepare granules with a particle diameter of 15 mm. The prepared granules were dried in a vacuum oven at 105° C. for 3 h. Then put the material into a vacuum tube furnace, under the environment of nitrogen as a protective gas, first keep it at 300°C for 60 minutes, then raise the temperature to 900°C and keep it for 90 minutes, and finally cool it to 200°C with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com