System and method for treating and recycling aged resin wastewater in production process of epoxy resin

A technology of epoxy resin and production process, which is applied in the field of wastewater treatment of epoxy resin production, can solve the problems of low boiling point of composite solvent, low recovery rate of epoxy resin, sticky aging resin, etc., and achieve high utilization rate of water and heat energy , extensive market application prospects, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

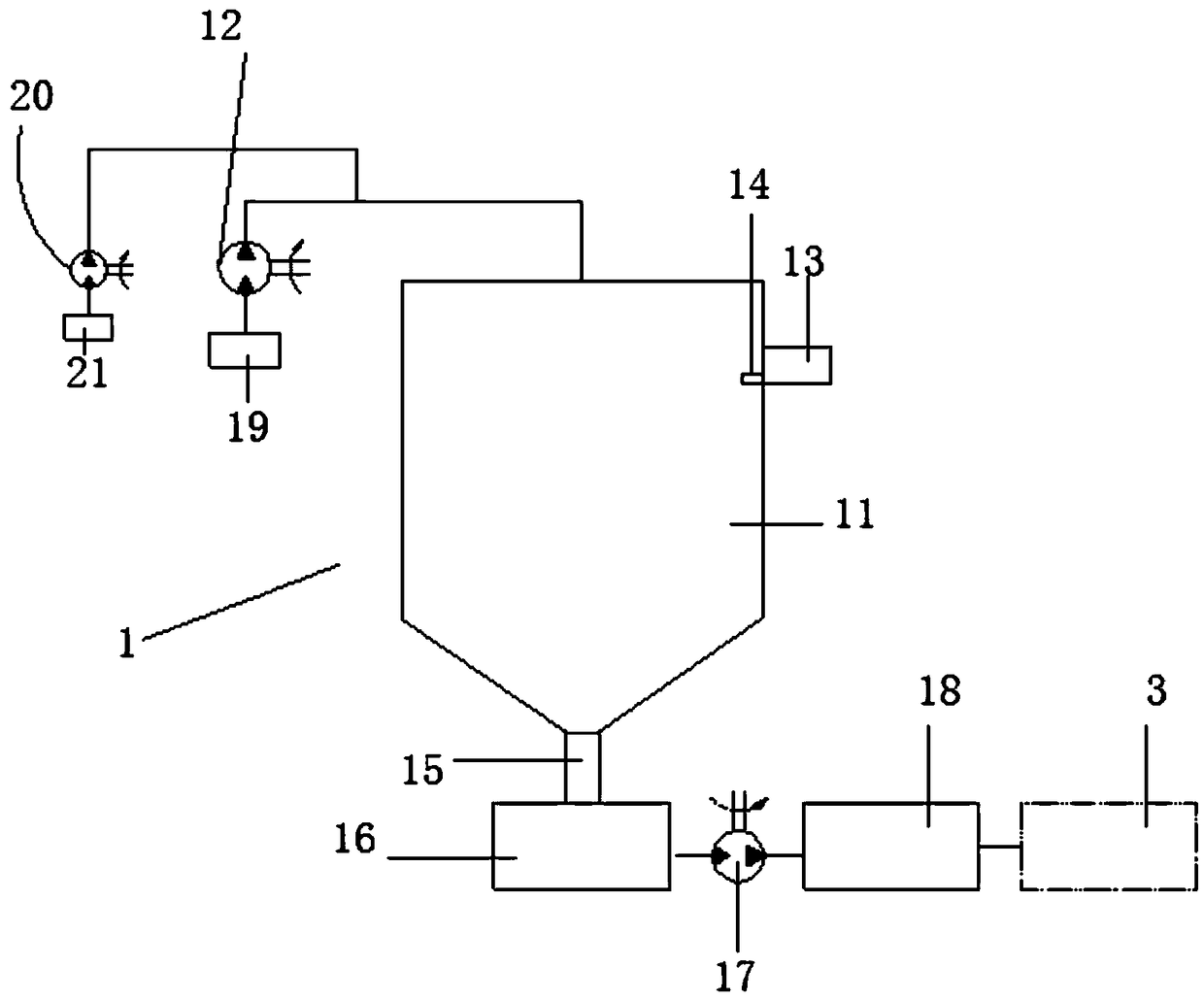

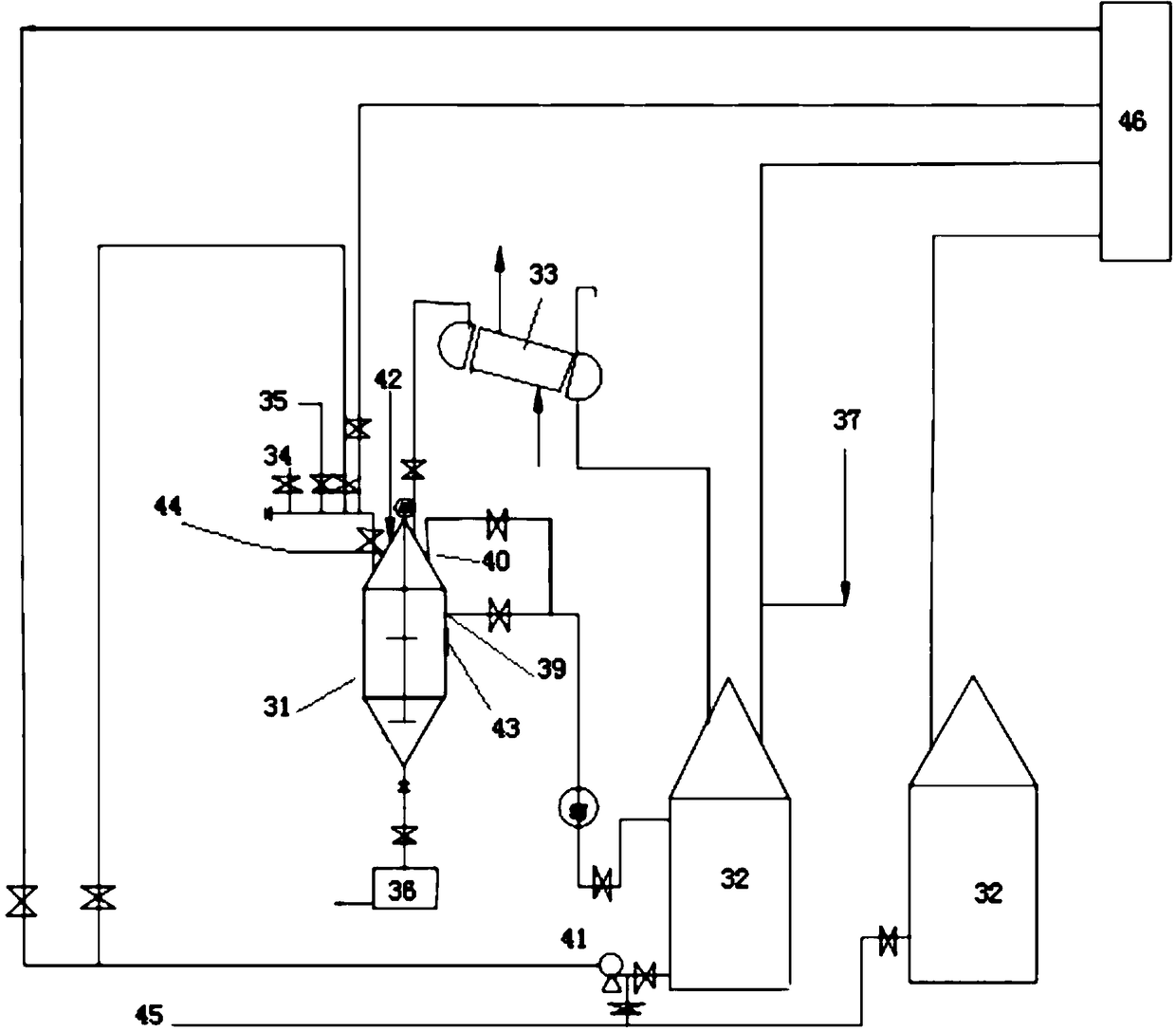

[0035] combine figure 1 , figure 2 , an aging resin waste water treatment and recovery system in the epoxy resin production process, comprising an aging resin precipitation compression device 1, an aging resin solvent extraction device 3, wherein the aging resin precipitation compression device includes a precipitation tank 11, a centrifugal pump 12, a screw pump 17, Plate and frame filter press 18, the inlet of the sedimentation tank 11 is connected to the outlet of the centrifugal pump 12 through a pipeline, the inlet of the centrifugal pump 12 is connected to the waste water container 19 through a pipeline, and a flocculant filling pipeline connected to the outlet pipeline of the centrifugal pump is provided, A valve is provided on the flocculant filling pipeline. The flocculant filling pipeline is connected to the polyacrylamide solution container 21, and a metering pump 20 is arranged on the flocculant filling pipeline. The outer clear water outflow pipe 13 is connecte...

Embodiment 2

[0042] combine figure 2 A method for treating and recycling aging resin waste water in an epoxy resin production process, comprising the following steps:

[0043] 1) Put the wastewater into the vertical flow sedimentation tank through the centrifugal pump through the pipeline mixer, and use the prepared polyacrylamide solution as the flocculant through the flocculant filling pipeline connected to the centrifugal pump outlet pipeline through the metering pump The ratio is added to the waste water, the waste water settles in the settling tank, the clear water flows out from the overflow weir of the transfer tank, and the aged resin after settling is discharged to the sludge tank through the discharge port at the bottom of the settling tank, and the sludge tank is pumped by the screw pump The aged resin is transported to the plate and frame filter press, compressed into a filter cake for subsequent processing;

[0044] 2) Solvent extraction process: add solvent to the aged resi...

Embodiment 3

[0060] The wastewater is pumped into the vertical flow sedimentation tank through the pipeline mixer through the centrifugal pump, and a flocculant adding line is added to the outlet pipeline of the centrifugal pump, and the prepared polyacrylamide solution is added to the wastewater in proportion through the metering pump. The waste water settles in the sedimentation tank, and the clear water flows out from the overflow weir of the transfer tank. The aged resin after precipitation is put into the sludge tank at the bottom discharge valve, and is pumped by the screw pump to the plate and frame filter press, and the filter cake is compressed. deal with. Add the aging resin in the sludge tank to the solvent, the ratio is aging resin:solvent = 1:1, the solvent is a mixed solvent of toluene-ethanol at 32:68, turn on the stirring device to fully dissolve at 45°C, continue stirring for 2 hours, divide solution, the precipitate was filtered out, the solution was distilled, and the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com