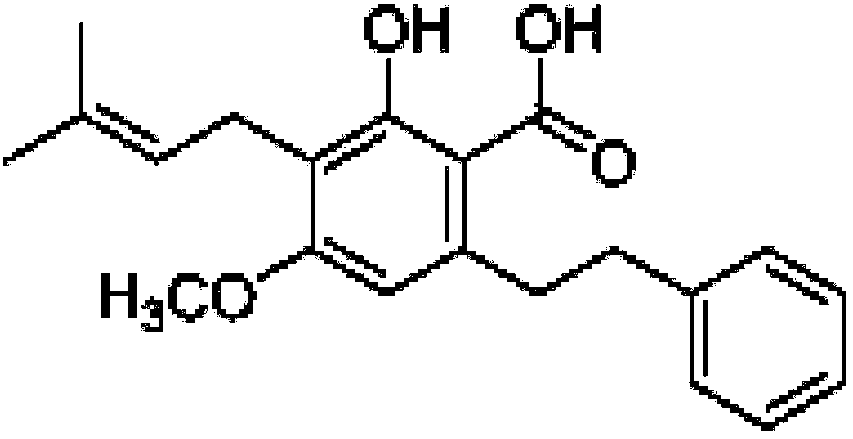

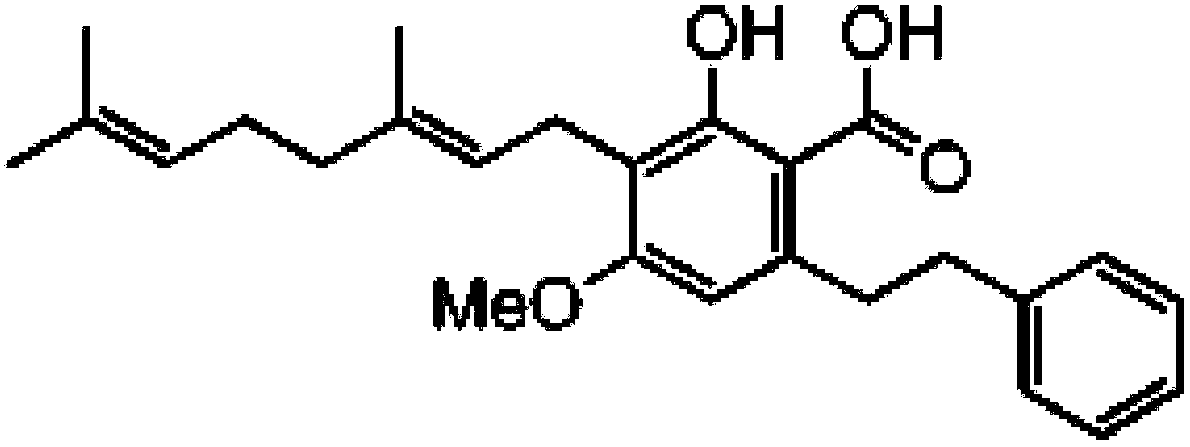

Method for preparing Amorfrutin A and Amorfrutin B from amorpha fruticosa fruits

An amorpha and fruit technology, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of unsuitability for industrial production, complex process, many by-products, etc., and achieves short cycle, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing Amorfrutin A and Amorfrutin B from amorpha fruit, comprising the following steps:

[0045] Step 1) subcritical extraction

[0046] Take 100Kg of Amorpha fruticosa fruit and crush it, pass it through a sieve of 80 mesh to 100 mesh, add 0.5 times the mass of cyclohexane and mix well, leave it at room temperature for more than 1 hour, then put it into the extraction kettle, the extraction pressure is 15MPa, and the extraction temperature is 30°C Under subcritical extraction for 2 hours, an oily extract was obtained;

[0047] Step 2) Remove impurities

[0048]Add 5 times its mass to the oily extract obtained in step 1), and add an ethylenediamine solution with a mass concentration of 10%, stir to dissolve, and collect the ethylenediamine solution layer, then add hydrochloric acid solution to the ethylenediamine solution layer Adjust the pH to 3-5, let stand, perform the first filtration, collect the precipitate and wash the precipitate to neutrality...

Embodiment 2

[0057] A method for preparing Amorfrutin A and Amorfrutin B from amorpha fruit, comprising the following steps:

[0058] Step 1) subcritical extraction

[0059] Take 100Kg of Amorpha fruticosa fruit and grind it through a 80-mesh to 100-mesh sieve, add acetone equal to its mass and mix well, place it at room temperature for more than 1 hour, and then put it into an extraction kettle with an extraction pressure of 25MPa and an extraction temperature of 50°C for sub- Critical extraction for 5 hours to obtain an oily extract;

[0060] Step 2) Remove impurities

[0061] In the oily extract that step 1) obtains, add its quality 15 times amount, the DMF solution that mass concentration is 20%, stir and dissolve, and collect DMF solution layer, then add citric acid solution in DMF solution layer and adjust pH to 3 ~ 5. Stand still, perform the first filtration, collect the precipitate and wash the precipitate with water until neutral;

[0062] Step 3) mixed solvent separation

[...

Embodiment 3

[0070] A method for preparing Amorfrutin A and Amorfrutin B from amorpha fruit, comprising the following steps:

[0071] Step 1) subcritical extraction

[0072] Take 100Kg of Amorpha fructus fruit and crush it, pass it through a sieve of 80-100 mesh, add 0.9 times its mass of dichloromethane and mix well, leave it at room temperature for more than 1 hour, then put it into the extraction kettle, the extraction pressure is 20MPa, and the extraction temperature is 40°C Under subcritical extraction for 3 hours, an oily extract was obtained;

[0073] Step 2) Remove impurities

[0074] To the oily extract obtained in step 1), add a triethylamine solution with 7 times its mass and a mass concentration of 15%, stir to dissolve, and collect the triethylamine solution layer, then add glacial acetic acid to the triethylamine solution layer Adjust the pH of the solution to 3-5, let it stand still, perform the first filtration, collect the precipitate and wash the precipitate to neutrali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com