Ultra low film peeling voltage polyurethane protective film, and preparation method thereof

A polyurethane, membrane voltage technology, applied in the direction of polyurea/polyurethane adhesive, conductive adhesive, film/sheet release liner, etc., can solve the problem of unsatisfactory antistatic effect, easy precipitation of antistatic agent, film body High internal impedance, to prevent breakdown and damage, high cross-linking density, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

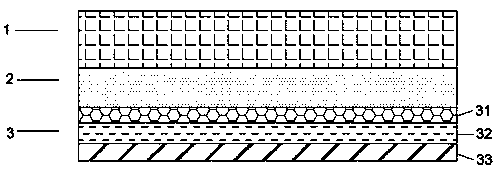

[0026] The preparation method of ultra-low tearing film voltage polyurethane protective film of the present invention, the method comprises the steps:

[0027] (1) Mix polyurethane, curing agent and antistatic agent in an organic solvent and stir evenly to prepare a polyurethane adhesive mixture;

[0028] (2) The polyurethane adhesive mixture obtained in step 1) of the corona surface coating of the internally added antistatic PET layer;

[0029] (3) The antistatic adhesive layer obtained in step (2) is combined with the PET antistatic release film layer, and aged at 60°C for 72 hours.

[0030] The performance evaluation method of the ultra-low tearing voltage polyurethane protective film of the present invention is as follows: under the condition that the temperature is 23°C and the humidity is 55%, the resistance value of the rubber surface is measured, and the voltage between the rubber surface and the release film at the moment the release film is torn off As well as the d...

Embodiment 1

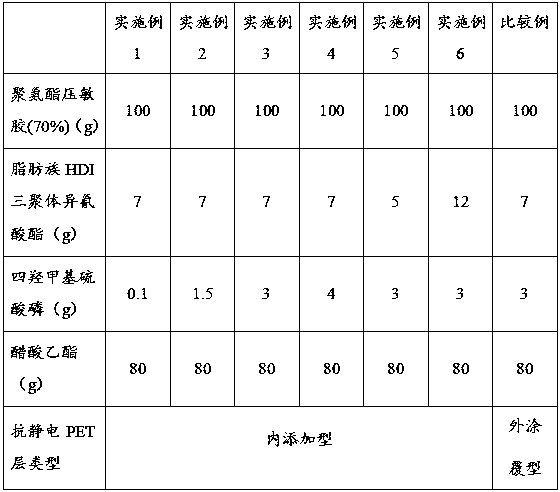

[0032] Embodiment 1: The formula composition and content of the polyurethane antistatic adhesive layer of this embodiment are: polyurethane pressure-sensitive adhesive (70%) 100g, aliphatic HDI trimer isocyanate 7 g, tetrakis hydroxymethyl phosphorus sulfate 0.1 g , ethyl acetate 80g. The ultra-low tearing voltage polyurethane protective film of this embodiment includes an internally added antistatic PET layer with a thickness of 50 μm (the impedance of both sides is 10 10 Ohm), polyurethane antistatic adhesive layer (impedance of 10 9 ohm) and a PET antistatic release film layer with a thickness of 50 μm (antistatic resistance of silicone oil surface 10 9 ohm).

[0033] The preparation method of the ultra-low tearing voltage polyurethane protective film of the present embodiment comprises the following steps:

[0034] (1) Mix 100g of polyurethane pressure-sensitive adhesive with a solid content of 70%, 7g of aliphatic HDI trimer isocyanate curing agent, 3g of tetrakis hydr...

Embodiment 2

[0037] Embodiment 2: The formula composition and content of the polyurethane antistatic adhesive layer of this embodiment are: polyurethane pressure-sensitive adhesive (70%) 100g, aliphatic HDI trimer isocyanate 7 g, tetrakis hydroxymethyl phosphorus sulfate 1.5 g , ethyl acetate 80g. The setting method of each layer of the ultra-low tearing voltage polyurethane protective film of this embodiment is the same as that of Embodiment 1. The preparation method of the ultra-low tearing voltage polyurethane protective film of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com