Polyurethane potting glue for household water purification hollow fiber membranes, and preparation method thereof

A fiber film and polyurethane technology, applied in the field of sealant, can solve the problems of film thread climbing, colloid cracking, and difficult control of potting viscosity, and achieve the effect of satisfying hygiene and safety, improving product quality, and shortening waiting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

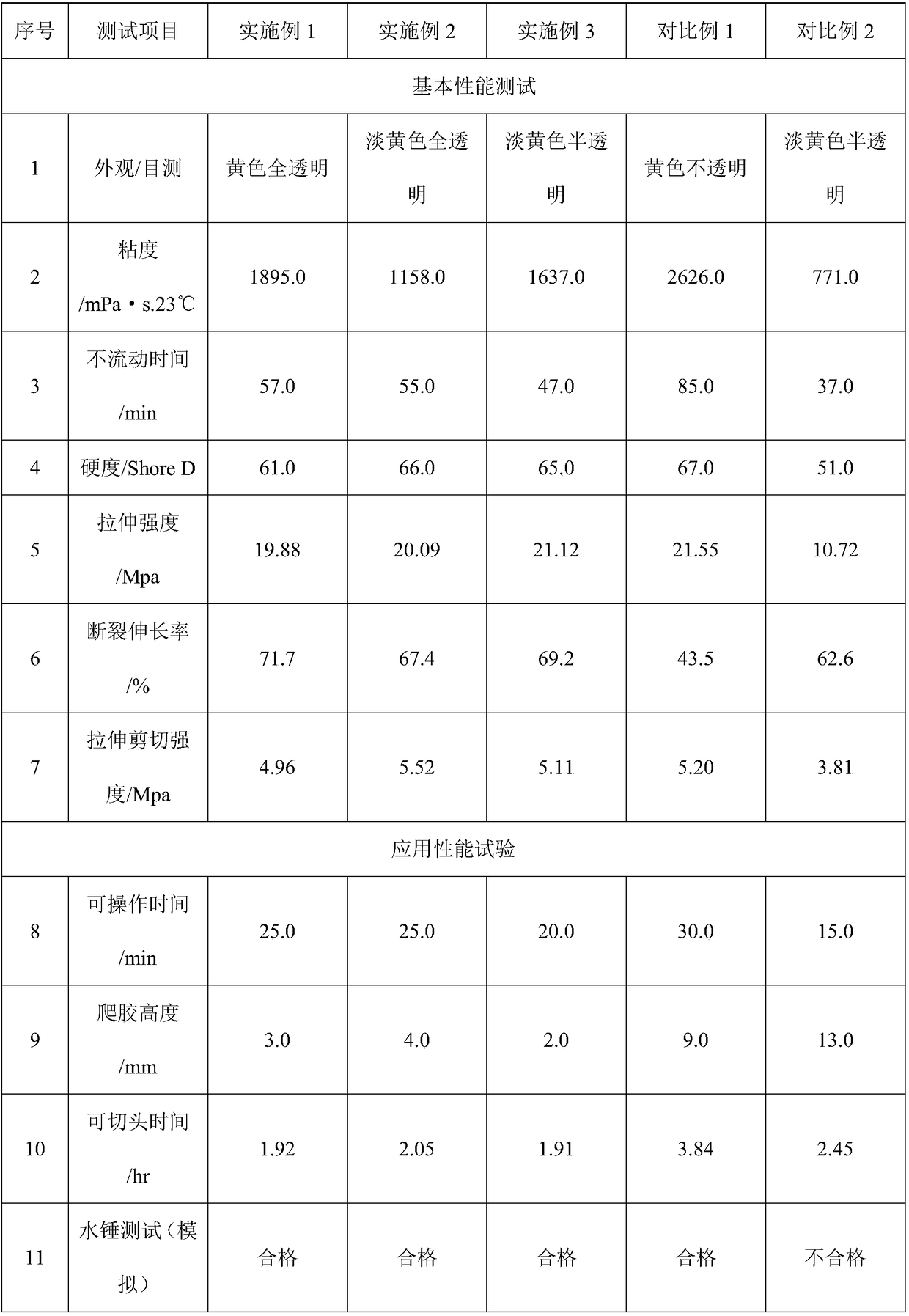

Examples

Embodiment 1

[0034] In the embodiment of the present invention, a polyurethane potting glue for household water purification hollow fiber membrane, its preparation method specifically includes:

[0035] Preparation of component A:

[0036] (1) Add 210.0 grams of first-grade castor oil, 30.0 grams of Sovermol 815, and 60.0 grams of A-20 in a dry and clean three-necked reaction flask equipped with a thermometer, stirring device, and vacuum pumping device, and set the stirring speed at 200 rpm, vacuum degree -0.098Mpa, and heat up to 110°C for 2 hours of refining;

[0037] (2) Keep stirring and vacuuming. After cooling down to below 50°C, add 0.3 grams of WE-D980 and 3.0 grams of WP480. After the addition is complete, continue stirring and vacuuming. The stirring speed is 350 rpm; after mixing well, add 1.5 grams Propyl isocyanate triethoxysilane and 0.001 g of PC-12, after the addition, continue to stir and vacuumize, the stirring speed is 200 rpm; after mixing evenly, add 3.0 g of R-2269, ...

Embodiment 2

[0057] This embodiment provides a polyurethane potting glue for household water purification hollow fiber membranes, and its preparation method specifically includes:

[0058] Preparation of component A:

[0059] (1) Add 240.0 grams of first-grade castor oil and 60.0 grams of 941VP successively in a dry and clean three-necked reaction flask equipped with a thermometer, a stirring device, and a vacuum pumping device. After adding, the stirring speed is set to 200 rpm, and the vacuum degree is - 0.098Mpa, and heat up to 110°C for 2 hours of refining;

[0060] (2) Keep stirring and vacuuming. After cooling down to below 50°C, add 0.6 grams of WE-D980 and 2.4 grams of WP480. After the addition is complete, continue stirring and vacuuming. The stirring speed is 350 rpm; after mixing well, add 0.6 grams Propyl isocyanate triethoxysilane and 0.0015 grams of KRBi-20, continue to stir and vacuumize after the addition, the stirring speed is 200 rpm; add 4.5 grams of R-2269 after the ad...

Embodiment 3

[0068] This embodiment provides a polyurethane potting glue for household water purification hollow fiber membranes, and its preparation method specifically includes:

[0069] Preparation of component A:

[0070] (1) Add 195.0 grams of first-grade castor oil, 75.0 grams of AC009, and 30.0 grams of D-290 in a dry and clean three-necked reaction flask equipped with a thermometer, a stirring device, and a vacuum pumping device, and set the stirring speed at 200 rpm after adding / min, vacuum degree -0.098Mpa, and heat up to 110°C for 2 hours of refining;

[0071] (2) Keep stirring and vacuuming. After cooling down to below 50°C, add 0.6 grams of AFCONA 7201 and 1.8 grams of WP480. After the addition, continue stirring and vacuuming. The stirring speed is 350 rpm; after mixing evenly, add 0.6 grams of iso Propyl trimethoxysilane cyanate and 0.0024 grams of KRBiZN8, after the addition, continue to stir and vacuum, the stirring speed is 200 rpm; after mixing evenly, add 3.0 grams of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com