Soil leavening agent and preparation method

A technology of soil leavening agent and polyvinyl alcohol, which is applied in the fields of soil preparation methods, soil conditioning materials, chemical instruments and methods, etc., to achieve the effects of increasing aggregate structure, reducing soil bulk density, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

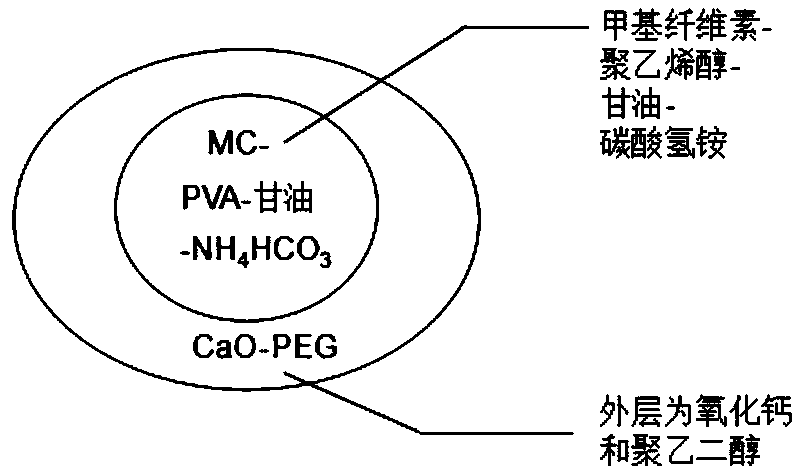

[0020] A kind of preparation method of soil leavening agent of the present invention, concrete operation steps are as follows:

[0021] Step 1, weigh the following materials according to mass percentage: polyvinyl alcohol with a molecular weight of 16000-20000Da 2-17.5%, glycerin 26.5-50%, methylcellulose with a molecular weight of 10000-15000Da 0.8-4%, powder particles with a molecular weight of 10000-15000Da, and more than 97% Ammonium bicarbonate with a diameter of 150-180 μm is 35.5-49%, polyethylene glycol with a molecular weight of 4000-20000Da is 0.5-12.6%, calcium oxide powder is 0.5-12.6%, and the sum of the mass percentages of the above components is 100%.

[0022] Step 2, co-melting polyvinyl alcohol and glycerin in an extruder and then extruding, the melting temperature is 120-130°C; then naturally cooling to room temperature to obtain a blend;

[0023] Step 3, adding methyl cellulose and ammonium bicarbonate to the blend, mixing evenly, and putting it into a granu...

Embodiment 1

[0027] Step 1, weigh the following materials: 5 g of polyvinyl alcohol with a molecular weight of 4000 Da, 80 g of glycerin, 3 g of methyl cellulose with a molecular weight of 10000 Da, 85 g of ammonium bicarbonate with a particle size of more than 97% of the powder being 150 μm, and polyvinyl alcohol with a molecular weight of 8000 Da. Ethylene glycol 1.5g, calcium oxide powder 1.5g.

[0028] Step 2, extruding polyvinyl alcohol and glycerin after co-melting in an extruder, the co-melting temperature is 120°C; then naturally cooling to room temperature to obtain a blend;

[0029] Step 3, adding methyl cellulose and ammonium bicarbonate to the blend, mixing evenly and putting it into a granulator for granulation to obtain mixed soft granules, wherein more than 97% of the mixed soft granules have a particle size of 0.8 mm;

[0030] Step 4, mix polyethylene glycol and calcium oxide powder in the coating pan evenly, then add the mixed soft granules into the coating pan, mix evenly...

Embodiment 2

[0032] Step 1, weigh the following materials: 55g of polyvinyl alcohol with a molecular weight of 20000Da, 100g of glycerin, 8g of methyl cellulose with a molecular weight of 15000Da, 155g of ammonium bicarbonate with a particle size of more than 97% of the powder being 180 μm, and polyvinyl alcohol with a molecular weight of 12000Da. Ethylene glycol 30g, calcium oxide powder 30g;

[0033] Step 2, extruding polyvinyl alcohol and glycerin after co-melting in an extruder, the co-melting temperature is 130°C; then naturally cooling to room temperature to obtain a blend;

[0034] Step 3, adding methyl cellulose and ammonium bicarbonate to the blend, mixing evenly, and putting it into a granulator to granulate to obtain mixed soft granules, wherein more than 97% of the mixed soft granules have a particle size of 1.0mm;

[0035] Step 4, mix polyethylene glycol and calcium oxide powder in the coating pan evenly, then add the mixed soft granules into the coating pan, mix evenly, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com