A novel submicron-scale radioactive film source and its preparation method

A submicron-level, radioactive technology, applied in the application of radioactive source radiation, obtaining electric energy from radioactive sources, nuclear engineering, etc., can solve problems such as difficult to achieve and easy to damage the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

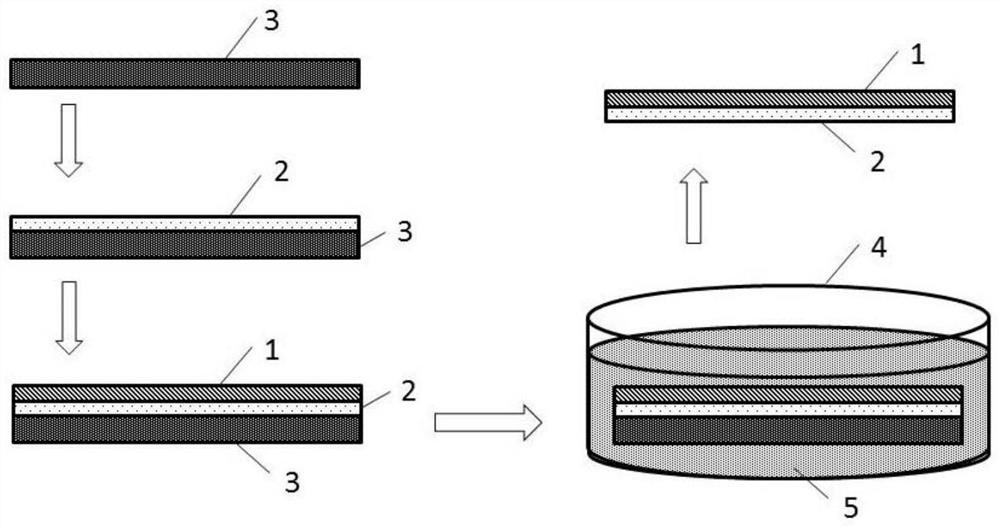

[0026] A method for preparing a novel submicron-scale radioactive film source, the steps of the method are as follows, and the flow process is as follows figure 1 Shown:

[0027] A: Select a suitable substrate material 3: copper foil (rolled oxygen-free copper, thickness 0.05mm, purity 99.95%, surface polishing), on the substrate material 3, use chemical vapor deposition (CVD) to grow and prepare graphene layer 2 : The copper foil that needs to grow graphene is ultrasonically cleaned in acetone, ethanol, and deionized water for 10 minutes, then ultrasonically cleaned with 25% hydrochloric acid for 10 minutes, and finally the copper foil is ultrasonically cleaned three times with deionized water, each time for 5 minutes. Place the cleaned copper foil in a CVD tube furnace in a hydrogen-argon gas mixture (volume ratio H 2 :Ar=1:9), the temperature was raised to 1000°C at a flow rate of 100 sccm (mL / min), and the temperature and gas flow were kept constant, annealed for 30 minut...

Embodiment 2

[0033] A method for preparing a novel submicron radioactive film source, the steps of the method are as follows:

[0034] A: Select suitable substrate material 3: aluminum foil (thickness of aluminum foil is 0.05mm, purity greater than 99.9%, surface polishing), and use chemical vapor deposition (CVD) to grow and prepare graphene layer 2 on substrate material 3: will need to grow The graphene aluminum foil was ultrasonically cleaned in acetone, ethanol, and deionized water for 10 minutes, then ultrasonically cleaned with 25% hydrochloric acid for 10 minutes, and finally the aluminum foil was ultrasonically cleaned with deionized water three times, each time for 5 minutes. The cleaned aluminum foil is placed in a CVD tube furnace, in a mixture of hydrogen and argon (volume ratio H 2 :Ar=1:9), the temperature was raised to 1000°C at a flow rate of 100 sccm (mL / min), and the temperature and gas flow were kept constant, annealed for 30 minutes, and then 5 sccm acetylene was introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com