A kind of preparation method of porous wood carbon modified metal lithium negative electrode material

A technology of negative electrode material and metal lithium, which is applied in the field of preparation of modified lithium metal negative electrode materials, can solve the problems of low coulombic efficiency and short cycle life of batteries, achieves simple and convenient preparation method, improves cycle life, and inhibits uncontrollable deposition behavior. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

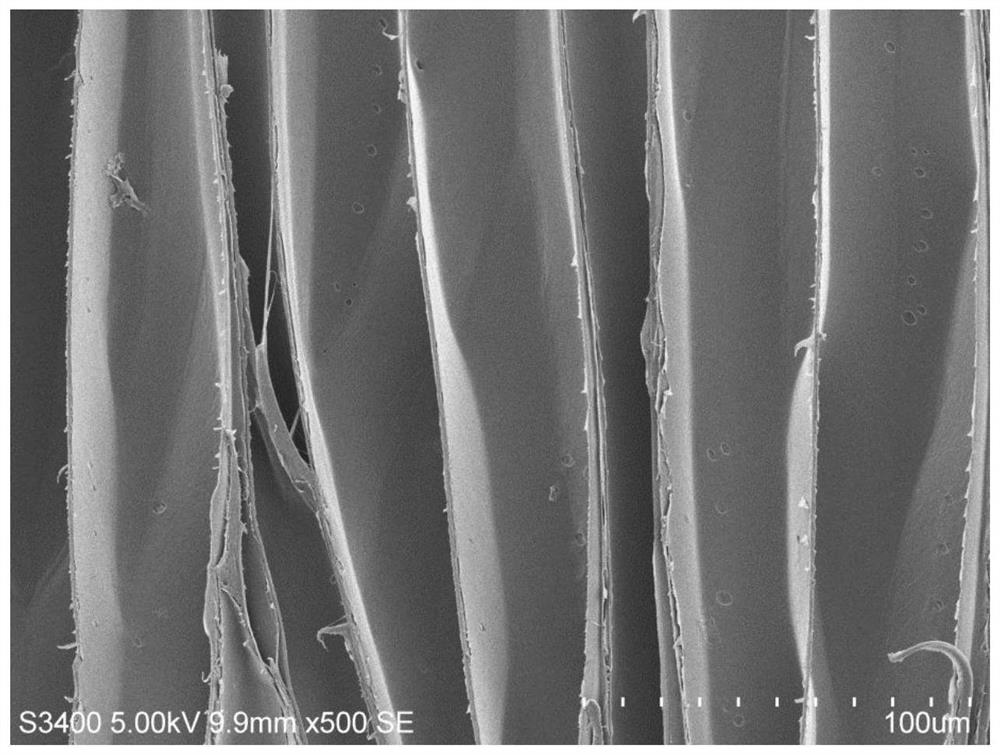

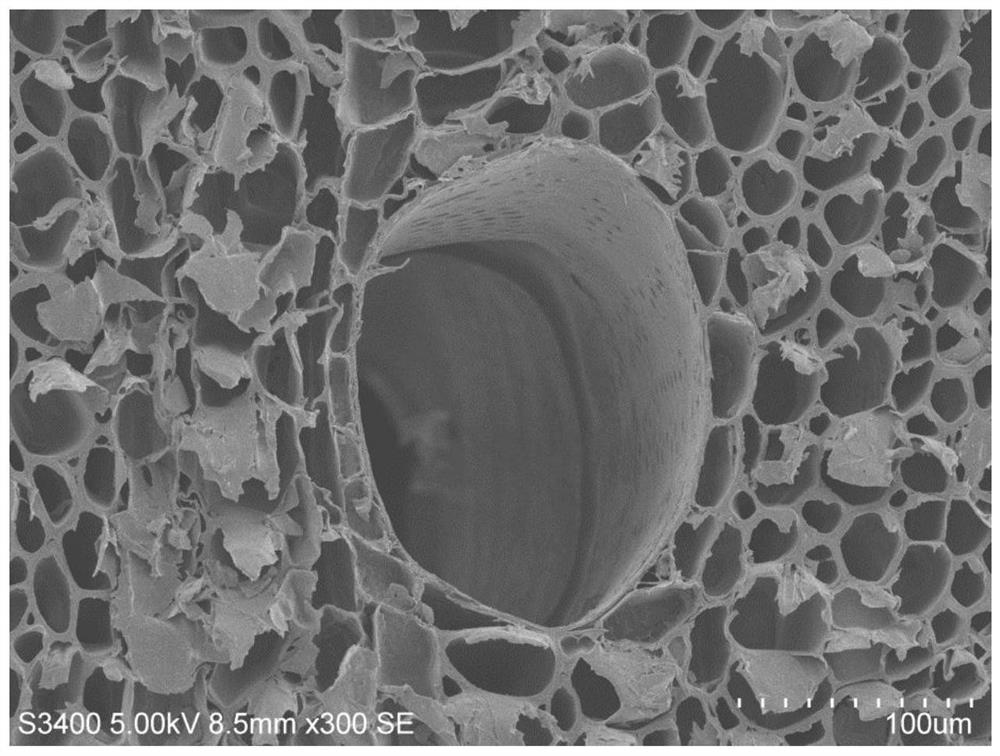

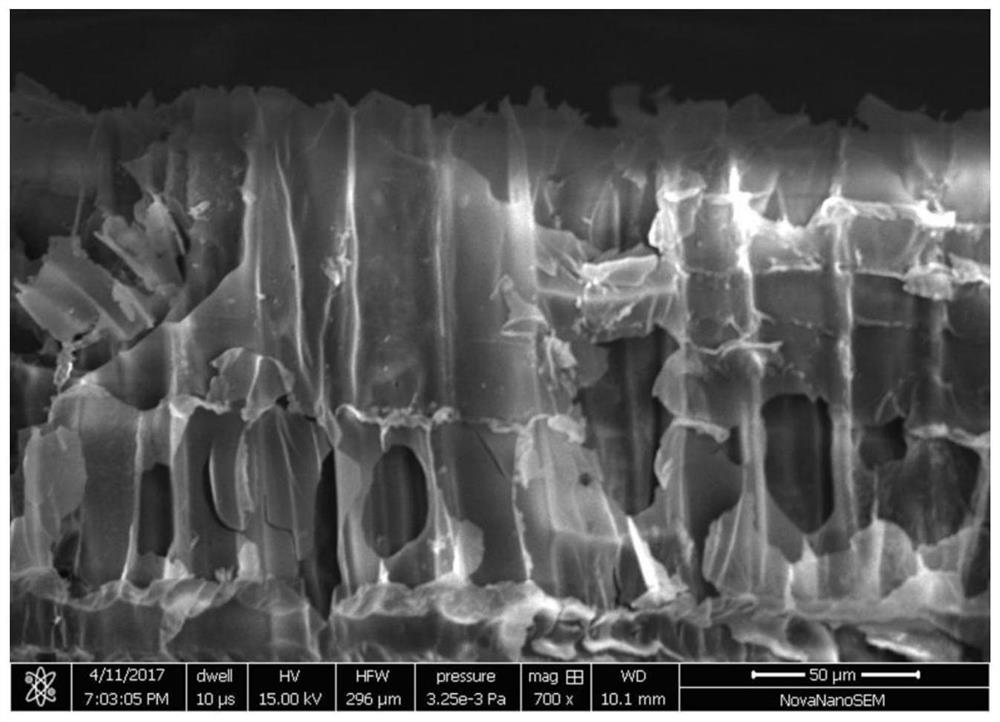

[0035] A kind of natural multilevel porous balsawood carbon modified metal lithium negative electrode material, its preparation method comprises the following steps:

[0036] (1) Get cross-cut balsa wood, cut into 1.2cm, wide 1.2cm, and thickness is the wood chip of 0.05cm;

[0037] (2) The balsa wood chips obtained in step (1) are heated to 300° C. for carbonization at a rate of 5° C. / min under a protective atmosphere, heat-insulated for 4 hours, then heated to 700° C. for activation at 5° C. / min, and heat-insulated for 2 hours. Obtain activated balsa wood carbon material (WC);

[0038] (3) 0.25g zinc nitrate is dissolved in 50mL ethanol, obtains the zinc nitrate ethanolic solution of 5mg / mL;

[0039] (4) Take 0.1 g of activated balsa charcoal obtained in step (2) and soak in the solution obtained in step (3) for 1 h. After taking it out, put it into a nitrogen-filled tube furnace, put 0.3g of polytetrafluoroethylene (PTFE) powder into a ceramic boat and place it in front of ...

Embodiment 2

[0042] A kind of natural multi-level porous balsa wood carbon modified metal lithium negative electrode material, its preparation method comprises the following steps: (1) get cross-cut balsa tree wood, cut length 1.2cm, width 1.2 centimeters, thickness is 0.05cm wood chips;

[0043] (2) The balsa wood chips obtained in step (1) are heated to 300° C. for carbonization at a rate of 5° C. / min under a protective atmosphere, heat-insulated for 4 hours, then heated to 700° C. for activation at 5° C. / min, and heat-insulated for 2 hours. Obtain activated balsa wood carbon material (WC);

[0044] (3) 0.25g magnesium acetate is dissolved in 50mL ethanol, obtains the magnesium acetate ethanol solution of 5mg / mL;

[0045] (4) Take 0.1 g of activated balsa charcoal obtained in step (2) and soak in the solution obtained in step (3) for 1 h. After taking it out, put it into a nitrogen-filled tube furnace, put 0.3g of polytetrafluoroethylene (PTFE) powder into a ceramic boat and place it i...

Embodiment 3

[0049] A kind of natural multilevel porous balsawood carbon modified metal lithium negative electrode material, its preparation method comprises the following steps:

[0050] (1) get cross-cut balsa wood, cut into 1.2cm, wide 1.2cm, thickness is the wood chip of 0.05cm;

[0051] (2) The balsa wood chips obtained in step (1) are heated to 300° C. for carbonization at a rate of 5° C. / min under a protective atmosphere, heat-insulated for 4 hours, then heated to 700° C. for activation at 5° C. / min, and heat-insulated for 2 hours. Obtain activated balsa wood carbon material (WC);

[0052] (3) 0.25g aluminum nitrate is dissolved in 50mL ethanol, obtains the aluminum nitrate ethanol solution of 5mg / mL;

[0053] (4) Take 0.1 g of activated balsa charcoal obtained in step (2) and soak in the solution obtained in step (3) for 1 h. After taking it out, put it into a nitrogen-filled tube furnace, put 0.3g of polytetrafluoroethylene (PTFE) powder into a ceramic boat and place it in front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com