Photocatalytic reaction gel membrane

A technology of photocatalytic reaction and gel film, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc. problems, to achieve the effect of reducing blocking effect, good light transmission, and maximizing the lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

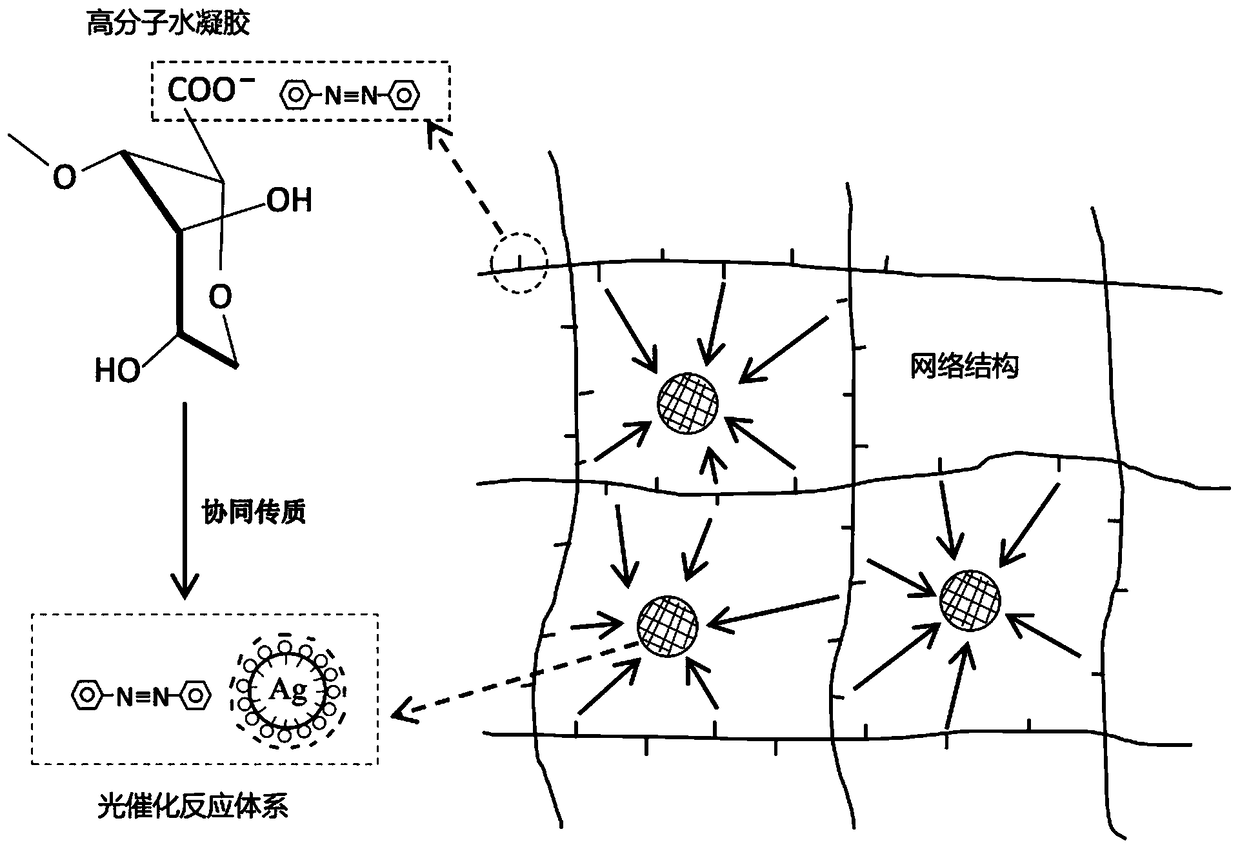

[0034] A photocatalytic reaction gel film, such as figure 1 As shown, it is mainly composed of a polymer hydrogel film with a water absorption rate of 92% and a photocatalytic reaction system. The content of the photocatalytic reaction system in the photocatalytic reaction gel film is 2.47wt%, and the polymer hydrogel film contains adsorption site, the adsorption site adsorbs the photocatalytic reaction system and fixes it in the pores, and the polymer hydrogel film contains non-strongly adsorbed polar groups-COO - ,-COO -A non-strongly adsorbed polar group area is formed, in which the polymer hydrogel film is made of sodium alginate, and the photocatalytic reaction system is mainly composed of nano-silver and free alkyl chains of ammonium oleate complexes and adsorbed on nano- The alkyl chains of the ammonium oleate complexes on the silver surface are interpenetrated to form a coating layer. The coating layer is wrapped on the surface of nano-silver. The average particle siz...

Embodiment 2

[0036] A photocatalytic reaction gel film, mainly composed of a polymer hydrogel film with a water absorption rate of 91% and a photocatalytic reaction system, the content of the photocatalytic reaction system in the photocatalytic reaction gel film is 2.40wt%, and the polymer water The gel film contains adsorption sites, which absorb the photocatalytic reaction system and fix it in the pores. The polymer hydrogel film contains non-strongly adsorbed polar groups-COO - ,-COO - A non-strongly adsorbed polar group region is formed, in which the polymer hydrogel film is made of potassium alginate, and the photocatalytic reaction system is mainly composed of nano-silver and the alkyl chain of free ammonium oleate complex and adsorbed on the nano- The alkyl chains of ammonium oleate complexes on the silver surface are interpenetrated to form a coating layer, the coating layer is wrapped on the surface of nano-silver, the average particle size of nano-silver is 9nm, and the surface o...

Embodiment 3

[0038] A photocatalytic reaction gel film, mainly composed of a polymer hydrogel film with a water absorption rate of 90% and a photocatalytic reaction system, the content of the photocatalytic reaction system in the photocatalytic reaction gel film is 2.38wt%, and the polymer water The gel film contains adsorption sites, which absorb the photocatalytic reaction system and fix it in the pores. The polymer hydrogel film contains non-strongly adsorbed polar groups-COO - ,-COO - A non-strongly adsorbed polar group region is formed; among them, the polymer hydrogel film is made of sodium carboxymethyl cellulose, and the photocatalytic reaction system is mainly composed of nano-silver and free ammonium oleate complexes with alkyl chains and The alkyl chains of the ammonium oleate complex adsorbed on the surface of nano-silver are interpenetrated to form a wrapping layer. The wrapping layer is wrapped on the surface of nano-silver. The average particle size of nano-silver is 18nm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com