Biodegradable Zn-Na-series zinc alloy and preparation method thereof

A biodegradable zinc alloy technology, applied in medical science, surgery, etc., can solve the problem that zinc alloy is not suitable for medical implant materials, and achieve high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Composition, Preparation and Properties Testing of Biodegradable Zn-Na Binary Zinc Alloy.

[0063] The chemical composition of the four inventive examples of the zinc alloy is shown in Table 1-1, the added Na is 0.01-0.72%, and the balance is Zn. NaZn in the zinc alloy 13 The volume fraction of the second phase is 0.4-30%.

[0064] The preparation and processing flow of the zinc alloy is: continuous casting→hot extrusion→rolling. The raw materials for the continuous casting are metal Zn and Na according to the ratio of Table 1-1, they are put into the graphite crucible of the continuous casting equipment, after vacuuming, the high-purity argon gas is introduced into the protection, and then the graphite crucible is heated by induction. Raise the temperature to 620°C and keep the temperature for 10 minutes until the raw materials are melted and fully mixed under electromagnetic stirring. Heat the temperature of the graphite casting mold to 450°C, start the casting dev...

Embodiment 2

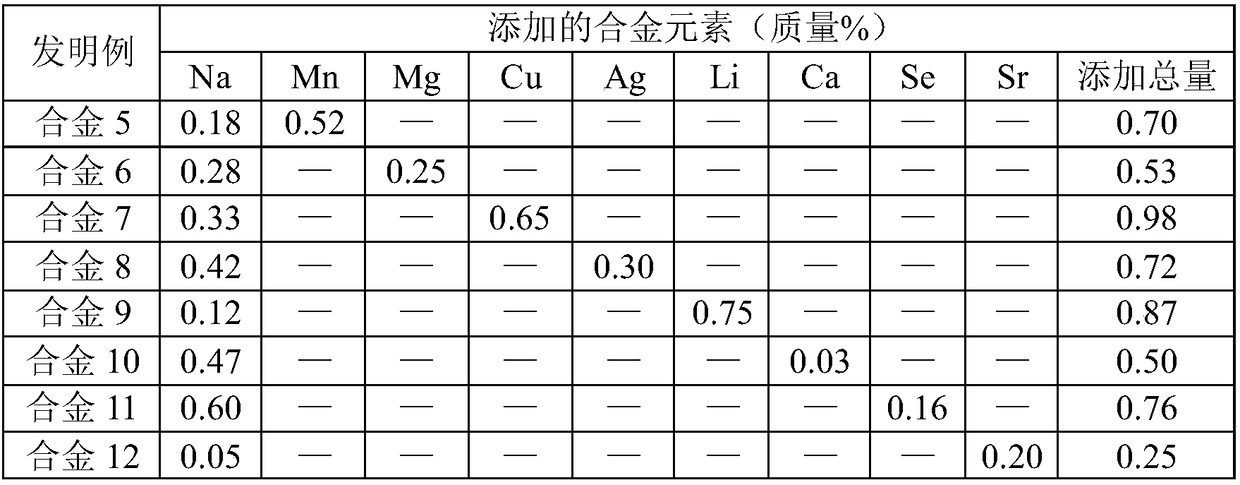

[0075] Composition, preparation and performance testing of biodegradable Zn-Na ternary zinc alloy.

[0076] The chemical composition of the 8 inventive examples of the zinc alloy is shown in Table 2-1. The total amount of alloying elements added is 0.25-0.98%, and the balance is Zn, which belongs to low-alloyed zinc alloy with low cost.

[0077] The preparation and processing flow of the zinc alloy is: continuous casting→hot extrusion→rolling. Use high-purity raw materials for batching according to the content of elements in Table 2-1, put them into the graphite crucible of the continuous casting equipment, put high-purity argon into the protection after vacuuming, and then raise the temperature of the graphite crucible to 650°C by induction heating , keep warm for 8 minutes until the raw materials are melted and fully mixed under electromagnetic force stirring. Heat the temperature of the graphite casting mold to 430°C, start the casting device to slowly pull the continuous ...

Embodiment 3

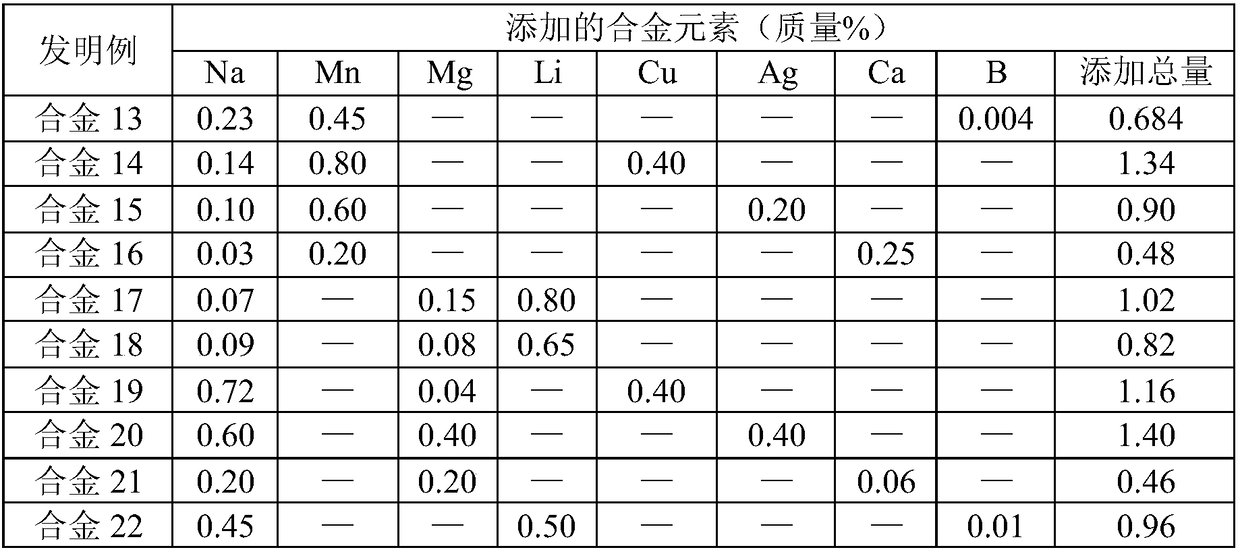

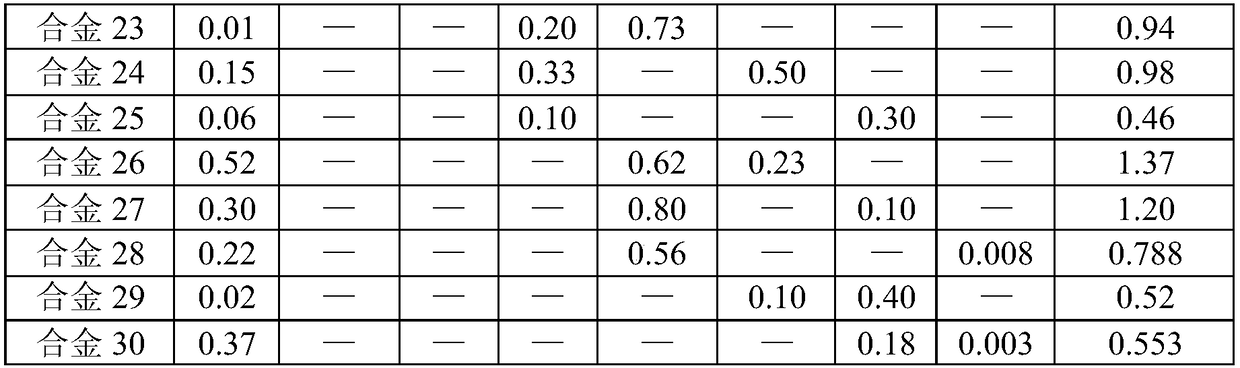

[0087] Composition, preparation and property test of biodegradable Zn-Na series quaternary zinc alloy.

[0088] The zinc alloy contains 4 alloying elements, 2 of which are essential alloying elements: Zn and Na, and the 3rd to 4th are further added alloying elements. The chemical composition of the 18 examples of the zinc alloy is shown in Table 3-1. The total amount of alloy elements added is 0.46-1.40%, and the balance is Zn, which belongs to low-alloyed zinc alloy and has low cost.

[0089] The preparation and processing flow of the zinc alloy is: continuous casting→homogenizing heat treatment→hot extrusion→rolling. Use high-purity raw materials for batching according to the content of elements in Table 3-1, put them into the graphite crucible of the continuous casting equipment, put high-purity argon into the protection after vacuuming, and then raise the temperature of the graphite crucible to 700°C by induction heating , keep warm for 5 minutes until the raw materials a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com