Electric knife bit for endoscopic submucosal dissection, and preparation method thereof

A peeling and mucous membrane technology, used in metal processing equipment, transportation and packaging, etc., can solve the problems of insufficient bonding strength of product interface, large equipment investment, long production cycle, etc., to avoid deformation, long service life, and excellent product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] A kind of preparation technology of endoscopic mucosal dissection (ESD) electric knife head, its process is as follows:

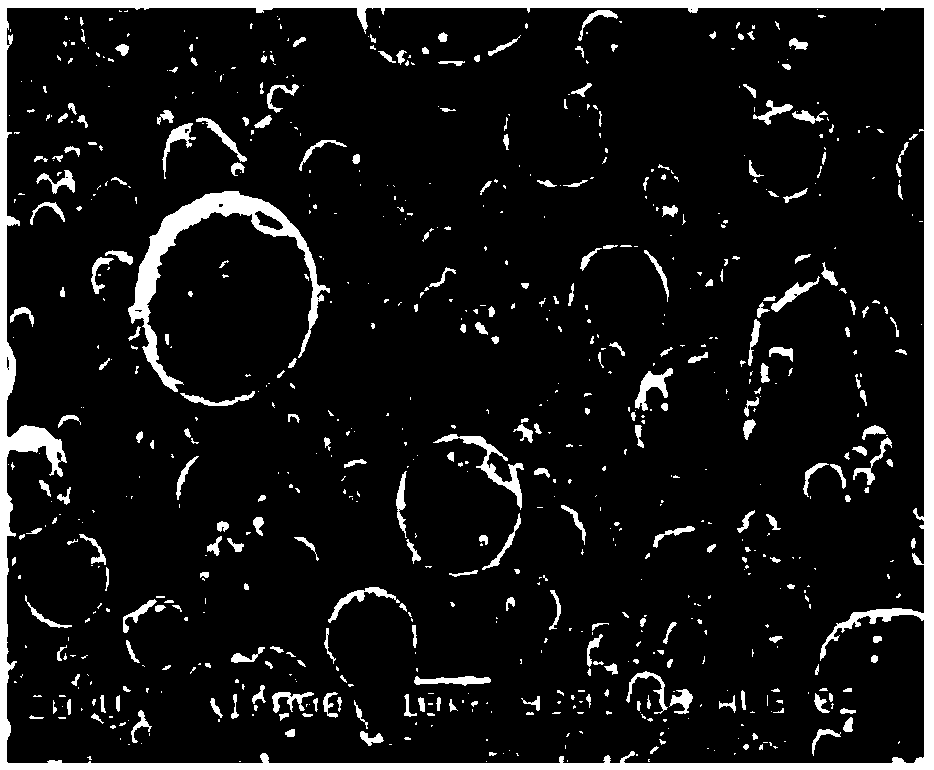

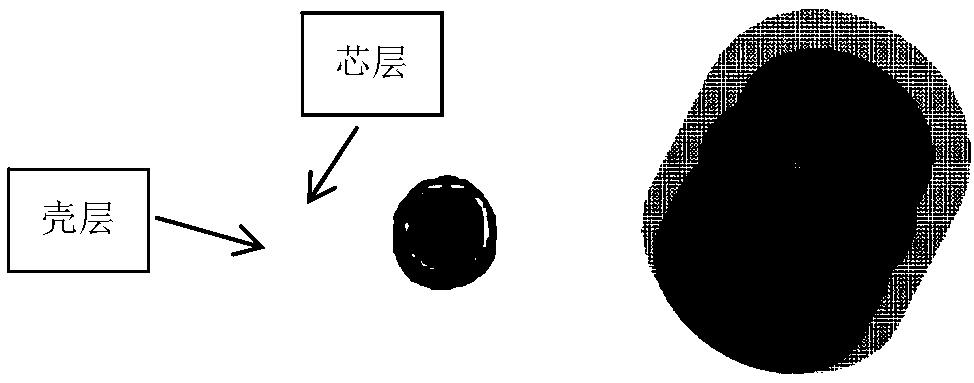

[0055] A. Raw material preparation: the shell material is 316L stainless steel gas-atomized powder with an average particle size of 22um provided by the British Osprey company. The chemical composition of the powder is shown in Table 1. figure 1 It is the SEM topography of 316L stainless steel powder; the core layer material uses ZrO with an average particle size of 45um 2 ceramic powder, figure 2 ZrO 2 Ceramic powder SEM topography;

[0056] Table 1 Chemical composition of 316L stainless steel powder

[0057]

[0058] B, preparation binder: by mass percentage, get paraffin wax (PW) 65%, polyethylene (PE) 19%, carnauba wax (CW) 15%, stearic acid (SA) 1%, at 140 ℃ of temperature Mix in a mixer for 2 hours to prepare the binder;

[0059] C. Preparation of feeding material: mixing and granulating the binder and shell material 316L stainless ste...

example 2

[0064] A kind of preparation technology of endoscopic mucosal dissection (ESD) electric knife head, its process is as follows:

[0065] A. Raw material preparation: the shell material is 316L stainless steel gas-atomized powder with an average particle size of 22um provided by the British Osprey company. The chemical composition of the powder is shown in Table 1. figure 1 It is the SEM topography of 316L stainless steel powder; the core layer material uses ZrO with an average particle size of 45um 2 ceramic powder, figure 2 ZrO 2 Ceramic powder SEM topography;

[0066] B, prepare binding agent: by mass percentage, get paraffin wax (PW) 69%, polyethylene (PE) 20%, carnauba wax (CW) 10%, stearic acid (SA) 1%, at 150 ℃ of temperature Mix in a mixer for 1.5h to prepare the binder;

[0067] C. Preparation of feeding material: mixing and granulating the binder and shell material 316L stainless steel powder according to the volume ratio of 40%:60% to make shell material feeding....

example 3

[0072] A kind of preparation technology of endoscopic mucosal dissection (ESD) electric knife head, its process is as follows:

[0073] A. Raw material preparation: the shell material is 316L stainless steel gas-atomized powder with an average particle size of 22um provided by the British Osprey company. The chemical composition of the powder is shown in Table 1. figure 1 It is the SEM topography of 316L stainless steel powder; the core layer material uses ZrO with an average particle size of 45um 2 ceramic powder, figure 2 ZrO 2 Ceramic powder SEM topography;

[0074] B, prepare binding agent: by mass percentage, get paraffin wax (PW) 72%, polyethylene (PE) 18%, carnauba wax (CW) 8%, stearic acid (SA) 2%, at 155 ℃ of temperature Mix in a mixer for 1 hour to prepare the binder;

[0075] C. Preparation of feeding material: mixing and granulating the binder and shell material 316L stainless steel powder according to the volume ratio of 42%:58% to make shell material feeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com