Preparation method of light-shadow image concrete building material

A concrete and image technology, applied in the field of building materials, can solve the problems of oversimplification, picture accuracy, poor sense of repetitive design, etc., and achieve good visual effects and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

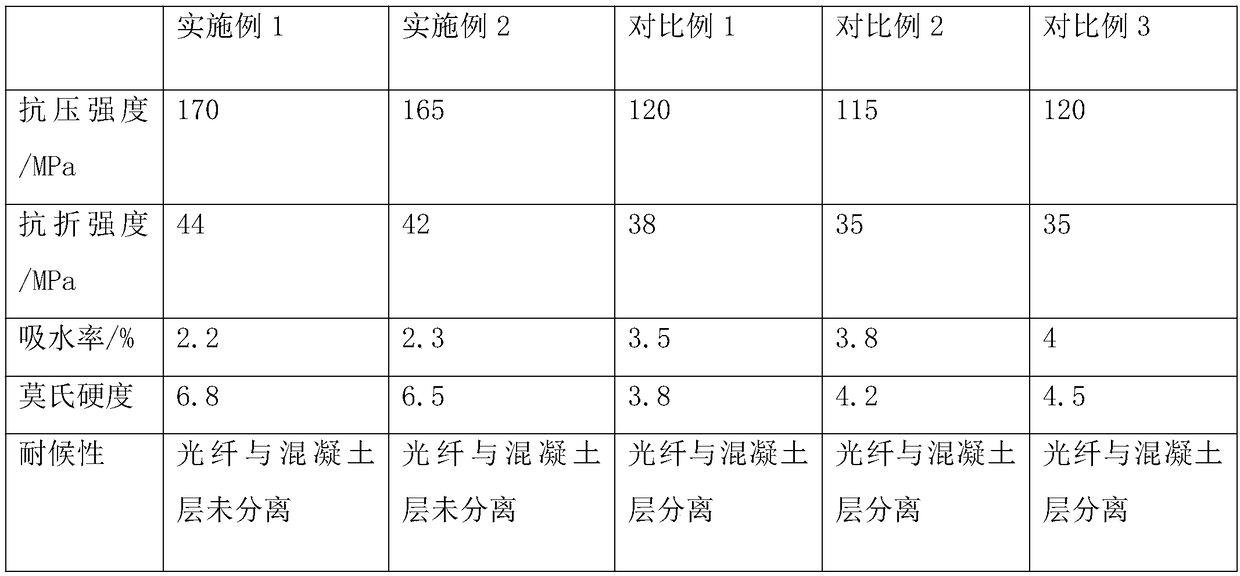

Examples

Embodiment 1

[0031] A method for preparing concrete building materials with light and shadow images, comprising the following steps:

[0032] 1) Weigh 38 parts of Portland cement, 12 parts of mineral powder, 8 parts of primary fly ash, 12 parts of metakaolin, 24 parts of quartz sand, and 6 parts of quartz powder according to weight ratio; polycarboxylate superplasticizer accounts for the total 1.4% of the total mass of the glue, water-retaining agent water-absorbing resin SPA accounts for 0.6% of the total mass of the glue, hydroxyethyl cellulose ether accounts for 0.05% of the total mass of the glue, and rubber powder accounts for 1.0% of the total mass of the glue , Iron oxide yellow pigment accounts for 3% of the total mass of cement, and glass fiber accounts for 2% of the total mass of the total adhesive material;

[0033] 2) After weighing all the raw materials in step 1), put them into the mixer for dry mixing for 3 minutes, weigh 9 parts of water and add them to the mixer for mixing...

Embodiment 2

[0036] A method for preparing concrete building materials with light and shadow images, comprising the following steps:

[0037] 1) Weigh 38 parts of Portland cement, 12 parts of mineral powder, 8 parts of primary fly ash, 12 parts of metakaolin, 24 parts of quartz sand, and 6 parts of quartz powder according to weight ratio; polycarboxylate superplasticizer accounts for the total 1.4% of the total mass of the glue, water-retaining agent water-absorbing resin SPA accounts for 0.6% of the total mass of the glue, hydroxyethyl cellulose ether accounts for 0.05% of the total mass of the glue, and rubber powder accounts for 1.0% of the total mass of the glue , Iron oxide yellow pigment accounts for 3% of the total mass of cement, and glass fiber accounts for 2% of the total mass of the total adhesive material;

[0038] 2) After weighing all the raw materials in step 1), put them into the mixer for dry mixing for 3 minutes, weigh 9 parts of water and add them to the mixer for mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com