Treatment method for electrolytic manganese residues

A technology of electrolytic manganese slag and treatment method, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as electrolytic manganese slag pollution, achieve increased strength, prevent heavy metals from Effects of Heavy Metal Ion Adsorption and Chelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

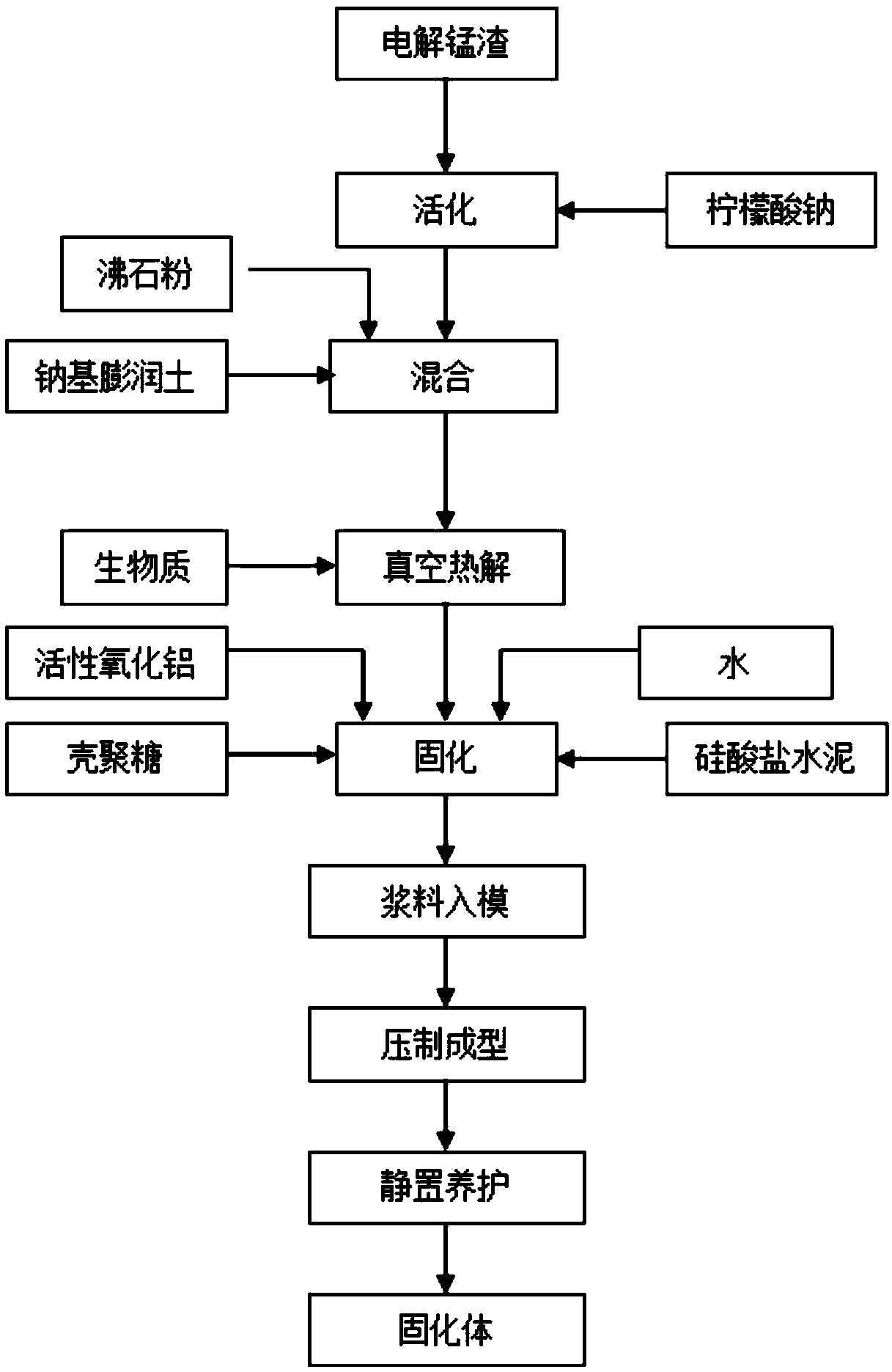

Image

Examples

Embodiment 1

[0026] Take electrolytic manganese slag, crush it into powder with a particle size range of 2-5 mm, add 0.1mol / L sodium citrate for soaking treatment for 24 hours; filter and dry to obtain acid-activated dry electrolytic manganese slag powder; The raw materials are mixed according to the mass ratio of 1:1, and the adsorption materials with a particle size of no more than 1mm are obtained after screening, and the adsorption materials are added to the electrolytic manganese slag powder according to 20% of the mass of the dry electrolytic manganese slag powder, and stirred to obtain a mixed powder Carry out vacuum co-pyrolysis of the obtained mixed powder and straw according to the mass ratio of 2:1, the temperature of vacuum pyrolysis is 500°C, and the pressure of the vacuum system is 1Kpa to obtain pyrolysis products, and then add thermal The chitosan powder that decomposes product quality is 5%, mixes and stirs to obtain mixture; Add in the mixture: account for the Portland cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com