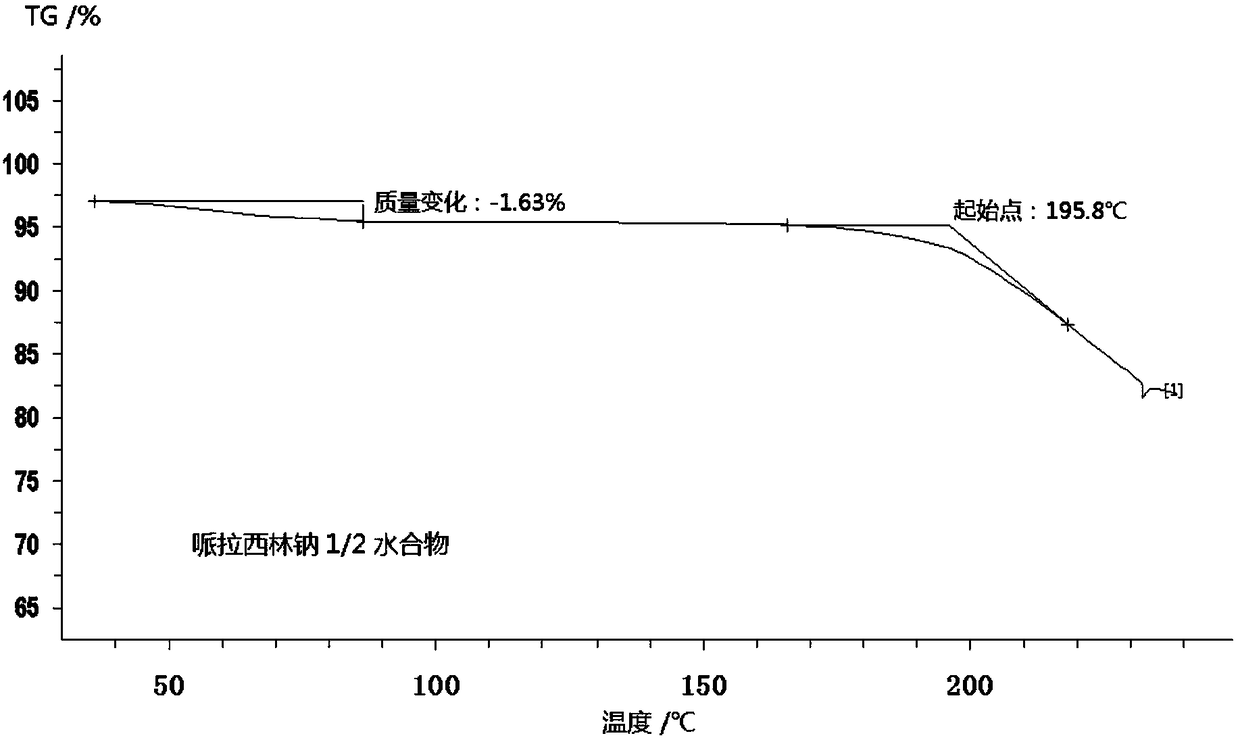

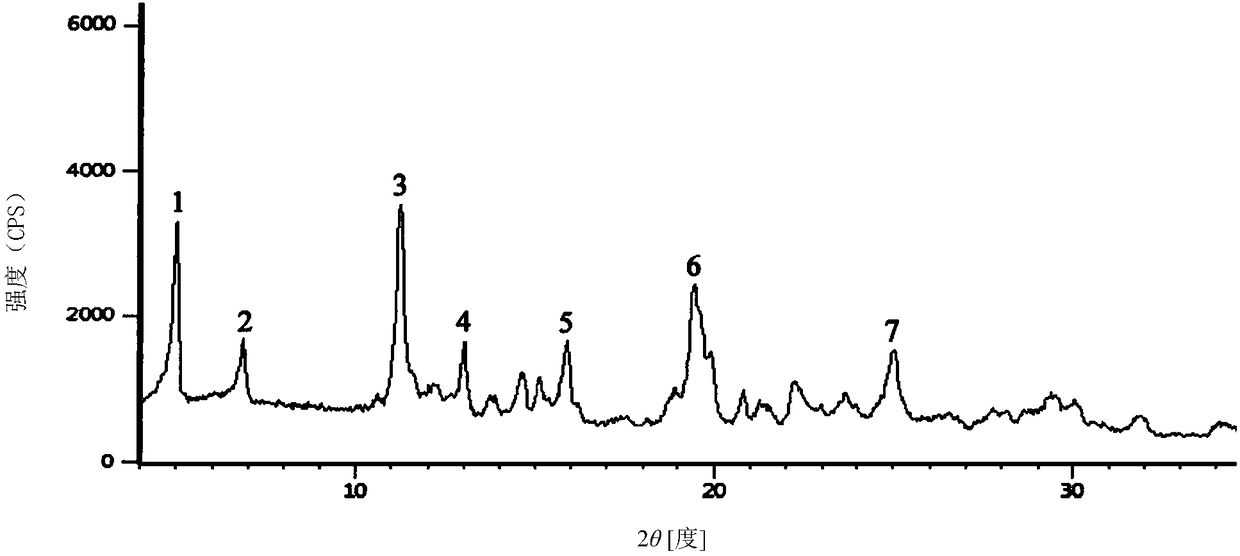

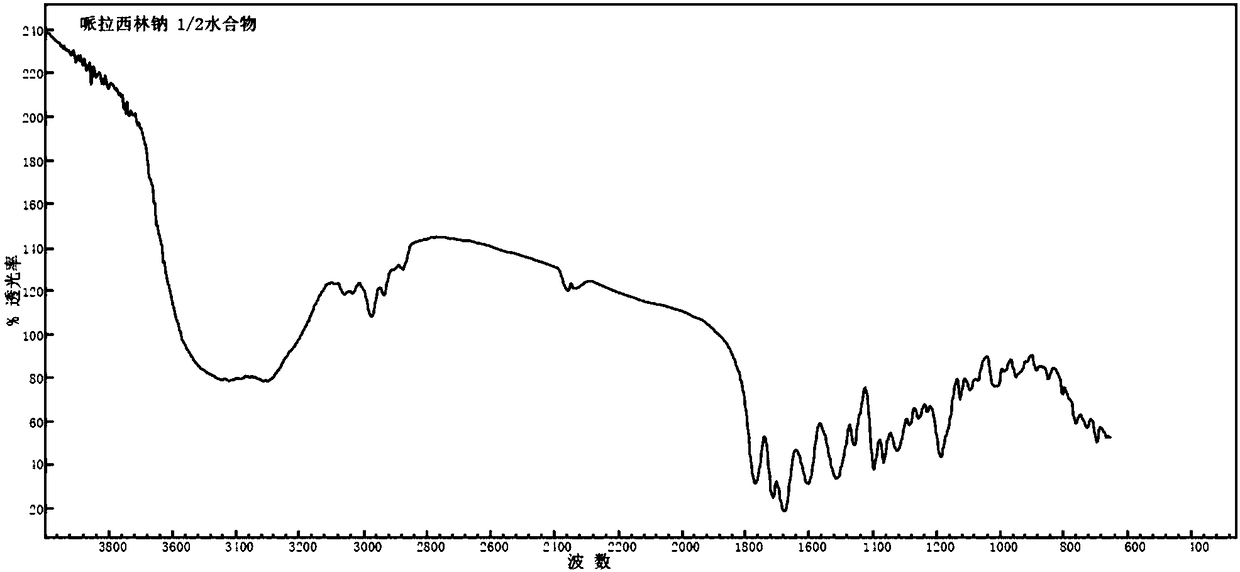

Piperacillin sodium compound containing half water

A technology of piperacillin sodium and compound, which is applied in the field of 1/2 water piperacillin sodium compound and its preparation method, can solve the problems of poor quality and stability, long production cycle, not conforming to the concept of energy saving and consumption reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of 1 / 2 water piperacillin sodium compound

[0030] 1. Preparation process:

[0031] (1) 100.4 g of ampicillin trihydrate, 200 mL of ethyl acetate and 400 mL of water were added to the reactor, and the reaction was stirred. Triethylamine was added dropwise to adjust the pH to 7.1, the temperature was controlled at 15-20°C, 65.9 g of 4-ethyl-2,3-dioxypiperazinecarbonyl chloride was added, and the reaction was incubated for 1 h. Activated carbon 5.0g was added, decolorized for 30min, and filtered. The aqueous layer in the filtrate was taken, added with an equal volume of ethyl acetate, adjusted to pH 1.6 with 2 mol / L hydrochloric acid, stirred for 2 h, filtered, and vacuum-dried at 30°C for 2.5 h to obtain 123.5 g of piperacillin acid as a white solid.

[0032] (2) Dissolve 123.5 g of the white solid above in a mixed solution of 1000 mL of acetone and 300 mL of water, cool down to 5°C, add 48.7 g of sodium acetate, and keep the temperature for 2 h. ...

Embodiment 2

[0037] Example 2 Preparation of 1 / 2 water piperacillin sodium compound

[0038] 1. Preparation process:

[0039] (1) 100.1 g of ampicillin trihydrate, 200 mL of ethyl acetate and 400 mL of water were added to the reactor, and the reaction was stirred. Triethylamine was added dropwise to adjust the pH to 7.5, the temperature was controlled at 15 to 20° C., 65.7 g of 4-ethyl-2,3-dioxypiperazinecarbonyl chloride was added, and the reaction was incubated for 1 h. Activated carbon 5.0g was added, decolorized for 30min, and filtered. The water layer in the filtrate was taken, added with an equal volume of ethyl acetate, adjusted to pH 1.9 with 2 mol / L hydrochloric acid, stirred for 2 h, filtered, and dried under vacuum at 35°C for 2 h to obtain 121.8 g of piperacillin acid as a white solid.

[0040] (2) 121.8g of above-mentioned white solid was dissolved in a mixed solution of 1050mL of acetone and 350mL of water, cooled to 8°C, 48.0g of sodium acetate was added thereto, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com