Sodium alginate-chitosan poly-ion composite hydrogel and preparation method thereof

A technology of polyion complex and sodium alginate, which is applied in the field of biomedical materials, can solve the problems of low mechanical strength of hydrogel, inability to match mechanical strength, and unstable existence of hydrogel, so as to achieve mild reaction conditions and realize The effect of controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

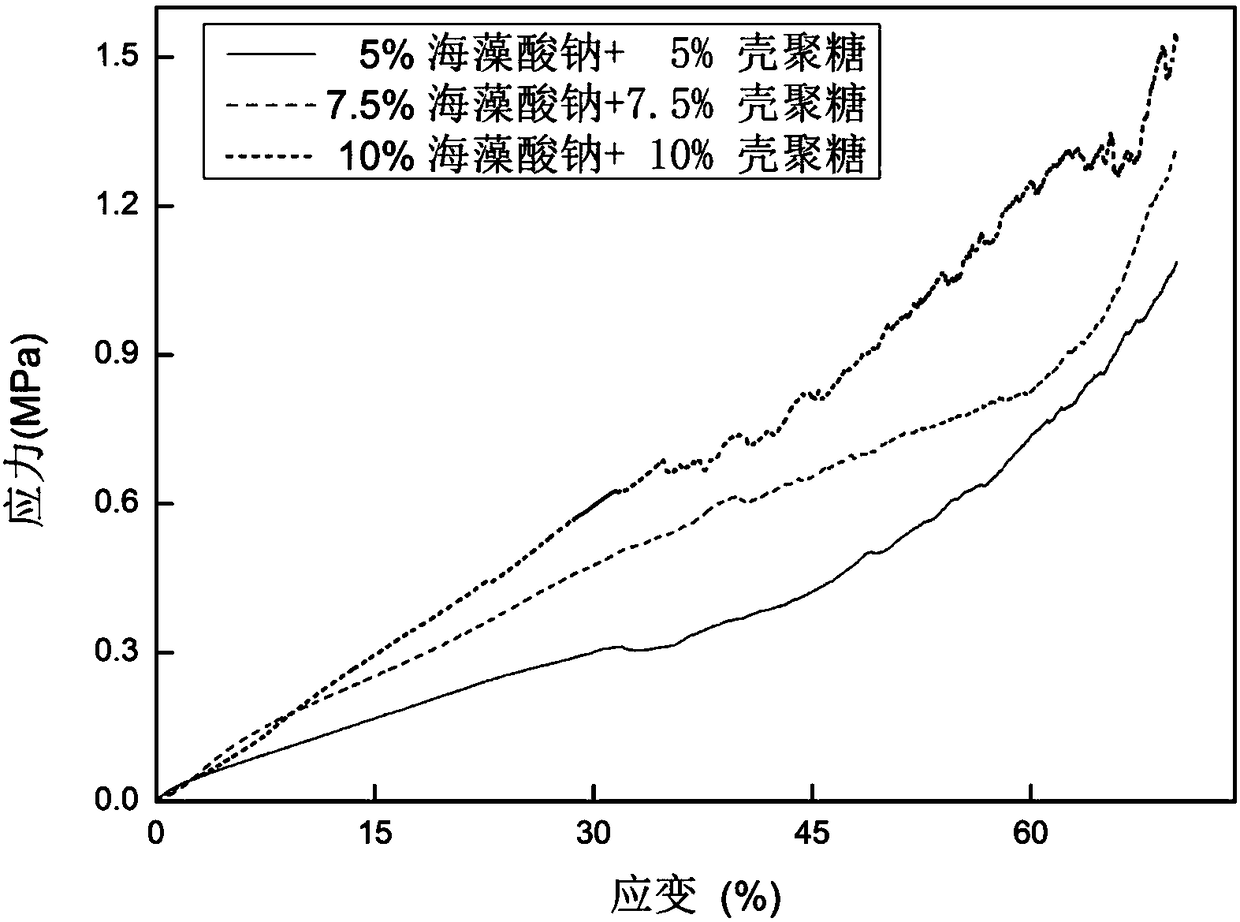

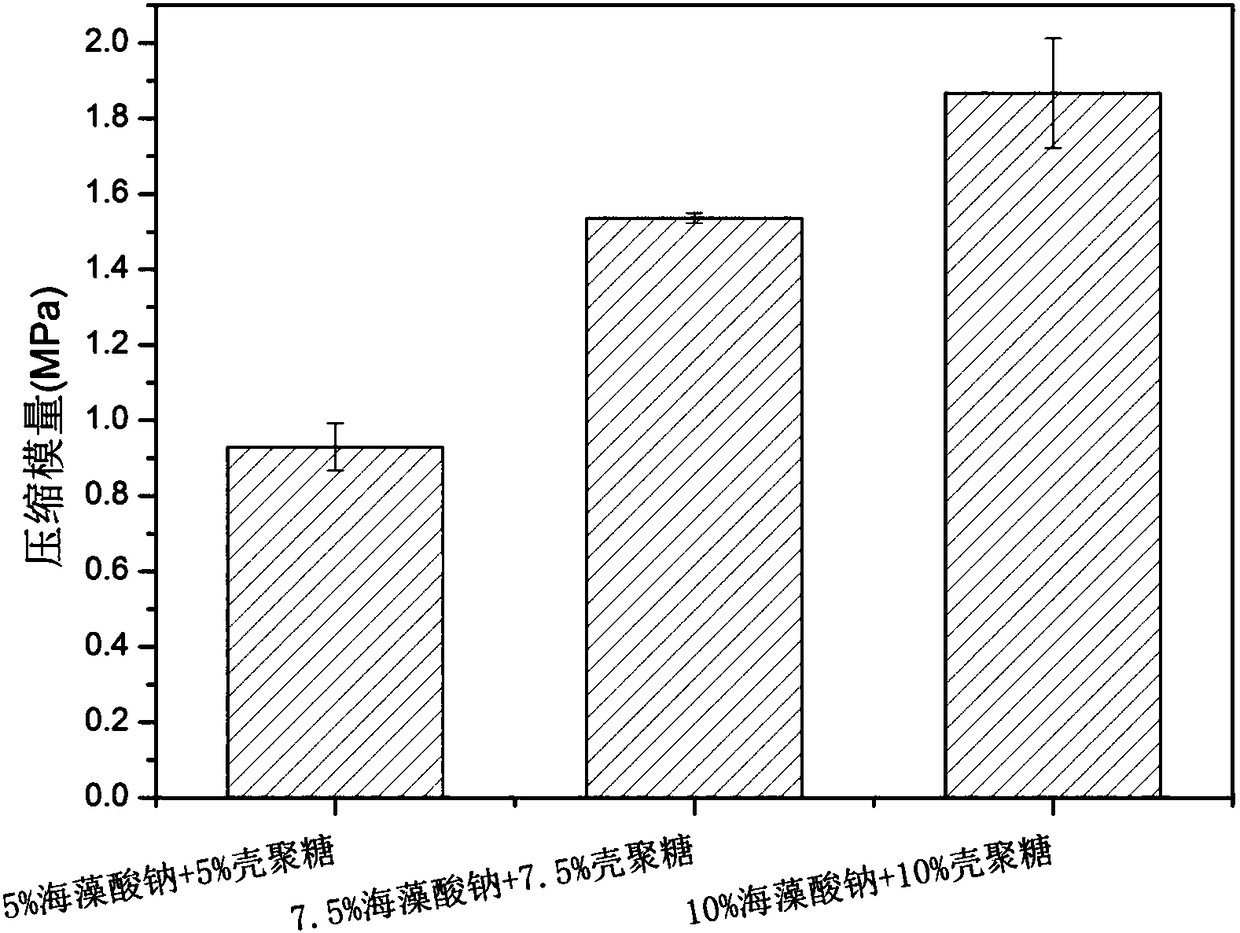

[0046] Take 2.5g of sodium alginate powder (Aladdin, S100126) and add it to 50mL of deionized water, and use a magnetic stirrer at room temperature to Fully stir for 2 hours to obtain a sodium alginate solution with a mass volume percentage concentration of 5% (w / v), then add 2.5g of chitosan powder (Aladdin, deacetylation degree ≥ 95%), and continue to fully stir for 2 hours to make the chitosan The powder is evenly dispersed in the sodium alginate solution to prepare a sodium alginate-chitosan polyion complex with a mass volume percentage concentration of 10% (w / v) and a mass ratio of sodium alginate to chitosan of 1:1 solution.

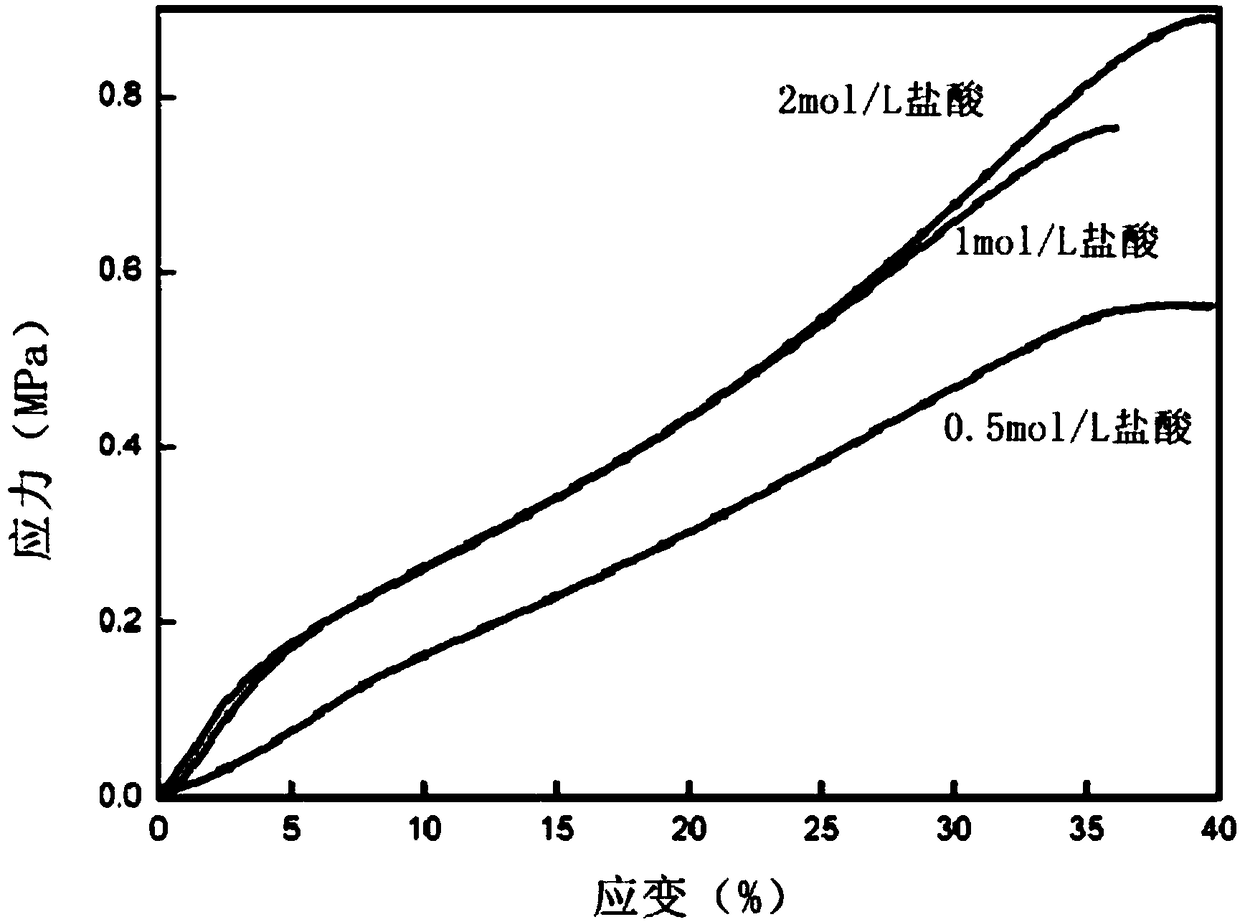

[0047]Inject the sodium alginate-chitosan polyion complex solution into a cylindrical mold, soak in 500 mL of hydrochloric acid solution with a molar concentration of 1mol / L for 20 hours, until sodium alginate reacts with chitosan to obtain sodium alginate- Chitosan polyion complex hydrogel, sodium alginate-chitosan polyion is prepared by ionic c...

Embodiment 2

[0049] Take 3.75g of sodium alginate (Aladdin, S100126) powder and add it to 50mL of deionized water, and use a magnetic stirrer at room temperature to Fully stir for 3 hours to obtain a sodium alginate solution with a mass volume percentage concentration of 7.5% (w / v), then add 3.75g of chitosan (Aladdin, deacetylation degree ≥ 95%) powder, continue to stir for 4 hours to make the chitosan The powder is evenly dispersed in the sodium alginate solution to prepare a sodium alginate-chitosan polyion complex with a mass volume percentage concentration of 15% (w / v) and a mass ratio of sodium alginate to chitosan of 1:1 solution.

[0050] Inject the sodium alginate-chitosan polyion complex solution into a cylindrical mold, soak in 500 mL of hydrochloric acid solution with a molar concentration of 1mol / L for 20 hours, until sodium alginate reacts with chitosan to obtain sodium alginate- Chitosan polyion complex hydrogel, sodium alginate-chitosan polyion is prepared by ionic cross-...

Embodiment 3

[0052] Take 5g of sodium alginate (Aladdin, S100126) powder and add it to 50mL of deionized water, and use a magnetic stirrer at room temperature to Fully stir for 4 hours to obtain a sodium alginate solution with a mass volume percentage concentration of 10% (w / v), then add 5g of chitosan (Aladdin, deacetylation degree ≥ 95%) powder, and continue to fully stir for 4 hours to make the chitosan powder Uniformly dispersed in sodium alginate solution to prepare a sodium alginate-chitosan polyion complex solution with a mass volume percent concentration of 20% (w / v) and a mass ratio of sodium alginate to chitosan of 1:1 .

[0053] Inject the sodium alginate-chitosan polyion complex solution into a cylindrical mold, soak in 500 mL of hydrochloric acid solution with a molar concentration of 1mol / L for 20 hours, until sodium alginate reacts with chitosan to obtain sodium alginate- Chitosan polyion complex hydrogel, sodium alginate-chitosan polyion is prepared by ionic cross-linking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com