Processing method for smelting TC4 alloy ingots by electron beam cold-bed furnace

An electron beam cooling hearth furnace and alloy ingot casting technology, which is applied in the field of titanium alloys, can solve the problems of quality level limitation and application, and achieve the effect of stability and reliability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

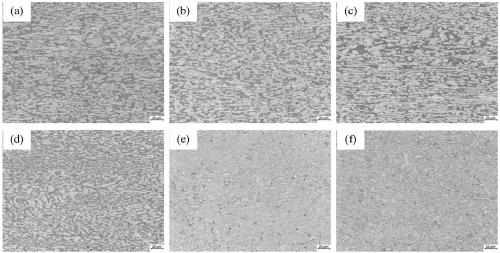

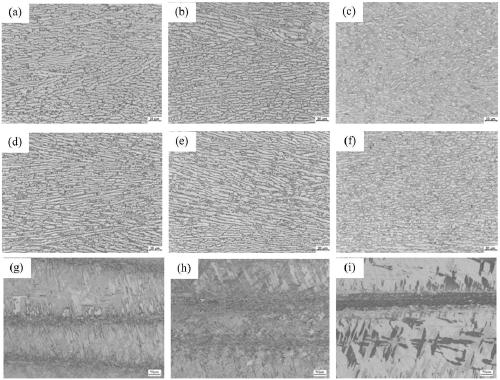

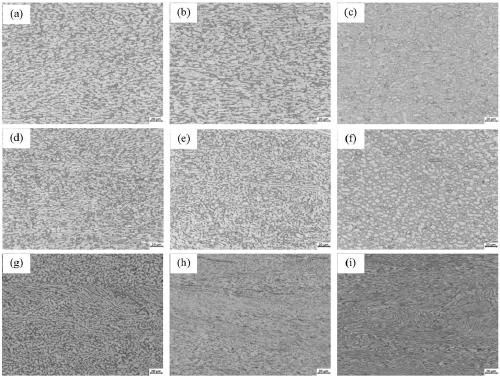

Image

Examples

Embodiment 1

[0033] Embodiment 1, one-time smelting of EB furnace prepares TC4 alloy flat ingot

[0034] The TC4 alloy slabs were produced by smelting TC4 alloy raw materials at one time by using an electron beam cooling hearth furnace, and the numbers were No.1, No.2, and No.3 respectively.

[0035] Table 1. Chemical composition of TC4 alloy slabs

[0036]

[0037] Above-mentioned production obtains the method for TC4 alloy flat ingot as follows:

[0038] Use the 3150KWB BMO-01 electron beam cooling hearth furnace imported from Ukraine, with sponge titanium (grade 1), aluminum vanadium master alloy (58V), aluminum beans, TiO 2 Powder and iron nails are TC4 alloy raw materials, and a single smelting is carried out according to the following steps to obtain TC4 alloy flat ingots:

[0039] 1) The stage of starting the electron gun: the liquid formed from starting the electron gun to the melting of raw materials flows into the crystallizer for the first time; wherein, the average vacuum ...

Embodiment 2

[0048] The processing method of embodiment 2, TC4 alloy flat ingot

[0049] 1. Direct rolling forming process

[0050] No.1 and No.2 ingots shown in Table 1 in Example 1 are directly rolled and heat treated to obtain TC4 alloy plates, as follows:

[0051] After the ingots were skinned and risers cut, the plate direct rolling test was carried out respectively. Among them, the No.1 and No.2 ingots were subjected to horizontal-longitudinal cross rolling and longitudinal rolling respectively, and the longitudinal rolling direction was the ingot solidification direction (Note: the ingot solidification method is continuous solidification, and the ingot specification H (thickness) × B (width) × L (length) as an example, then the L (length) direction is the continuous solidification and forming direction of the ingot, that is, the longitudinal direction; the B (width) direction is the transverse direction). After 2 / 4 heat rolling, a plate with thickness δ=25 / 8mm is obtained.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com