A light emit diode having a uniform electrode electric field distribution and a method for manufacture that same

A technology of light-emitting diodes and electric field distribution, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems that the improvement of the electric field at the edge of the electrode has no obvious effect, the improvement of the electric field at the edge of the electrode has no effect, and the distribution of the electric field of the electrode has not been mentioned, etc., to achieve relief Current crowding effect, improvement of light extraction efficiency, effect of weakening current crowding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

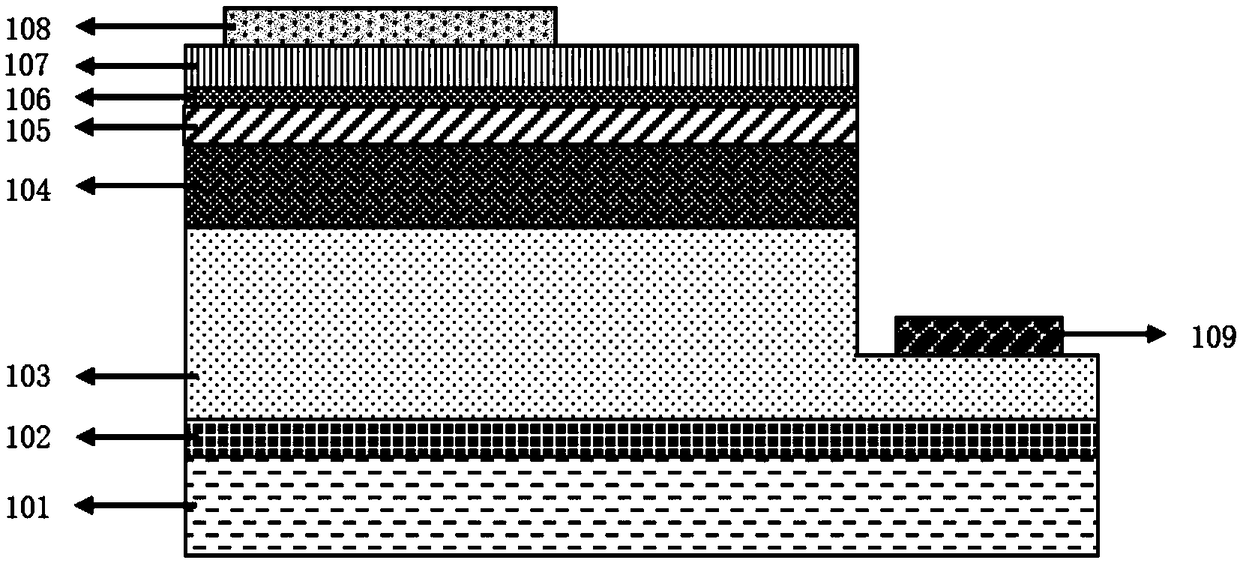

Embodiment 1

[0060] The light-emitting diode device with uniform electrode electric field distribution of this embodiment is such as Figure 7 As shown, along the epitaxial growth direction, it includes: epitaxial layer (substrate 101, buffer layer 102, N-type semiconductor transport layer 103, multiple quantum well layer 104, P-type semiconductor transport layer 105, P-type heavily doped semiconductor transport layer 106, current spreading layer 107), the N-type semiconductor transport layer 103 is partially exposed, and N-type ohmic electrodes 109 are distributed on the exposed N-type semiconductor transport layer 103; the current spreading layer 107 is distributed with The insulator layer 110 is covered with a P-type ohmic electrode 108; the insulating layer 110 is patterned with holes of the same size, and the thickness is 5nm; the P-type ohmic electrode 108 is divided into two parts , the lower part is distributed with columnar patterned electrodes matching the holes on the insulating...

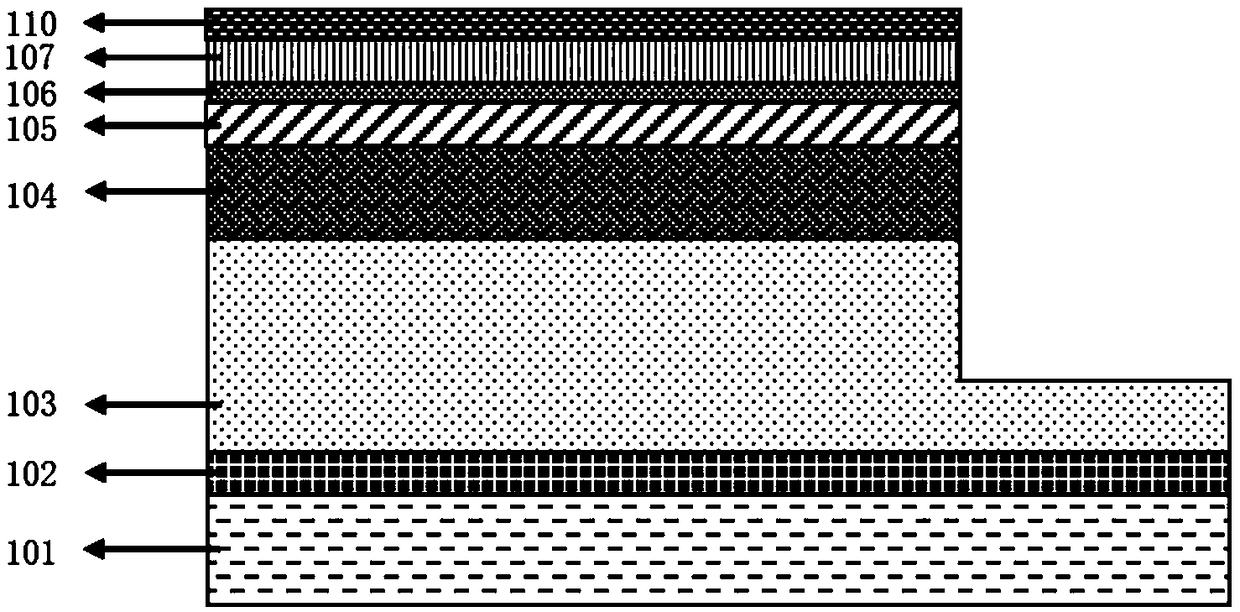

Embodiment 2

[0073] The light-emitting diode device with uniform electrode electric field distribution of this embodiment is such as Figure 7 As shown, along the epitaxial growth direction, it includes: epitaxial layers (substrate 101, buffer layer 102, N-type semiconductor transport layer 103, multiple quantum well layer 104, P-type semiconductor transport layer 105, P-type heavily doped semiconductor transport layer 106, current spreading layer 107), the N-type semiconductor transport layer 103 is partially exposed, and N-type ohmic electrodes 109 are distributed on the exposed N-type semiconductor transport layer 103; the current spreading layer 107 is distributed with The insulator layer 110 is covered with a P-type ohmic electrode 108; the insulating layer 110 is patterned with holes of the same size, and the thickness is 5nm; the P-type ohmic electrode 108 is divided into two parts , the lower part is distributed with columnar patterned electrodes matching the holes on the insulatin...

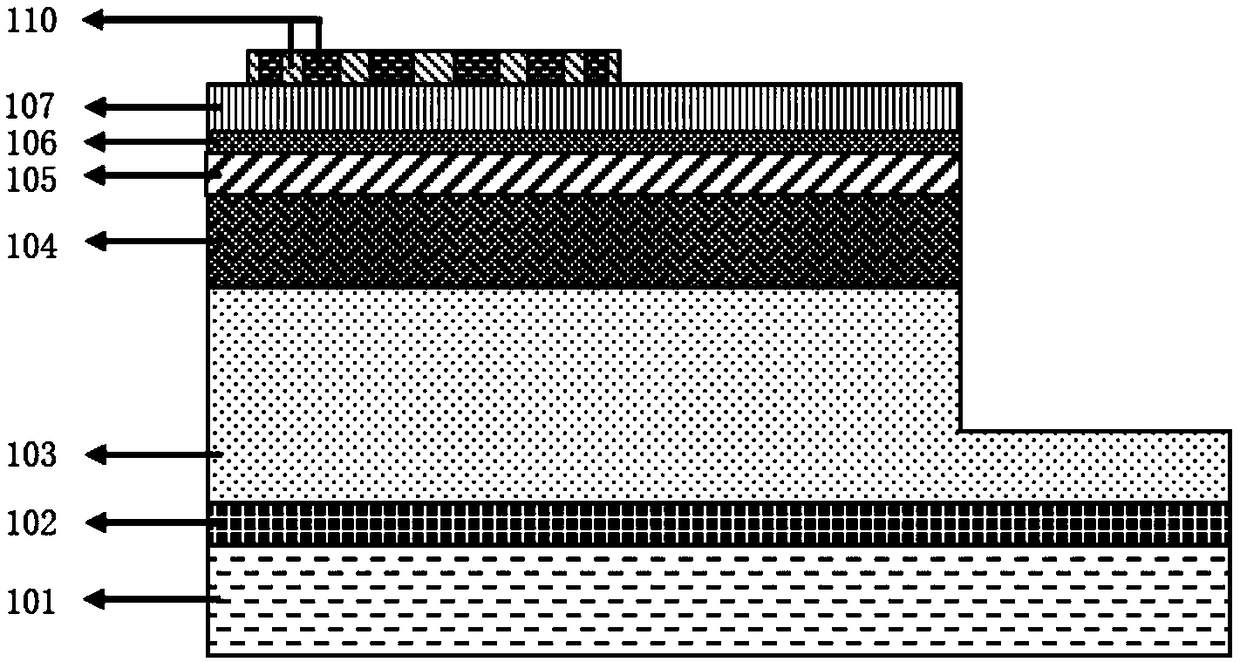

Embodiment 3

[0086] The material used in addition to the current spreading layer 107 is graphene; the insulator layer 110 first photoetches a cylindrical hole with a radius of 40 μm in the middle, and then photoetches a circle of cylindrical holes on the edge of the insulator layer 110, and every two cylindrical holes on the edge The distance between them is 200nm, the radius is 9.9μm, and the distance from the central cylindrical hole is 200nm (top view as Figure 9 ), other with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com