A lens and lens antenna based on 3D printing

A 3D printing and lens technology, used in antennas, electrical components, etc., can solve the problems of high processing cost of Lunberg lenses, difficult to achieve industrialization, and difficult to achieve miniaturization, and achieve high practicability, high design complexity, and high processing. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

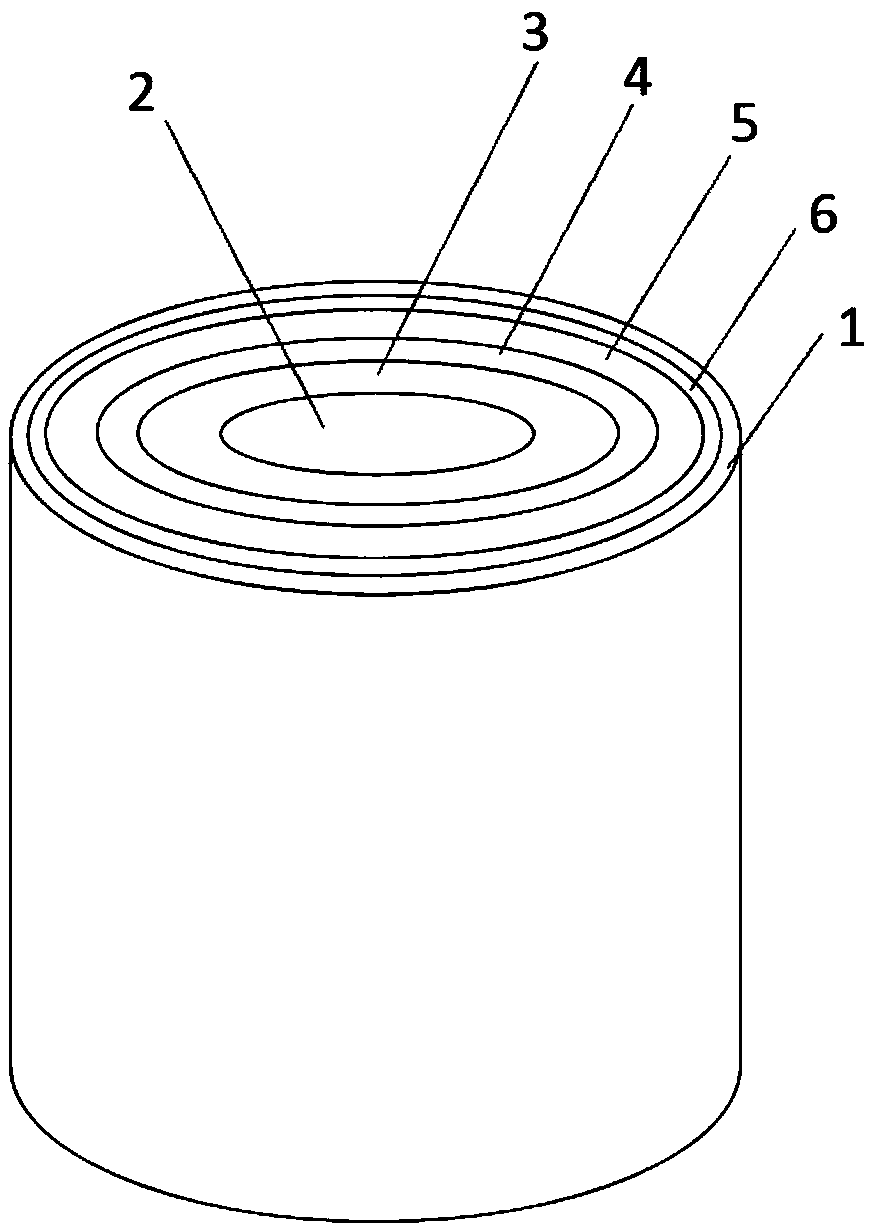

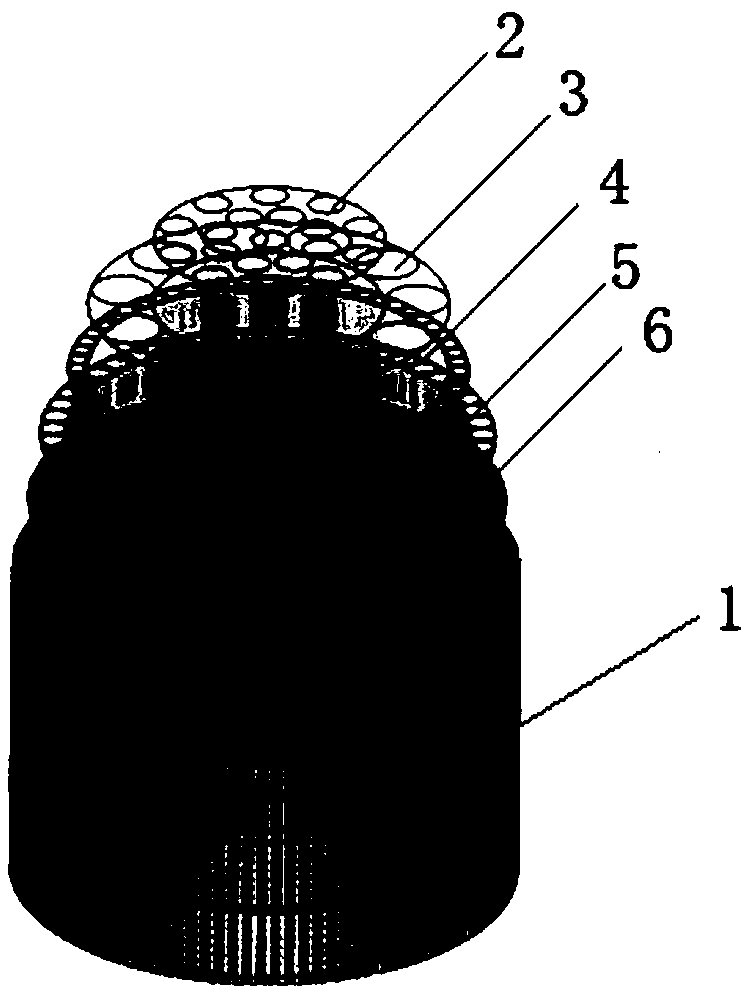

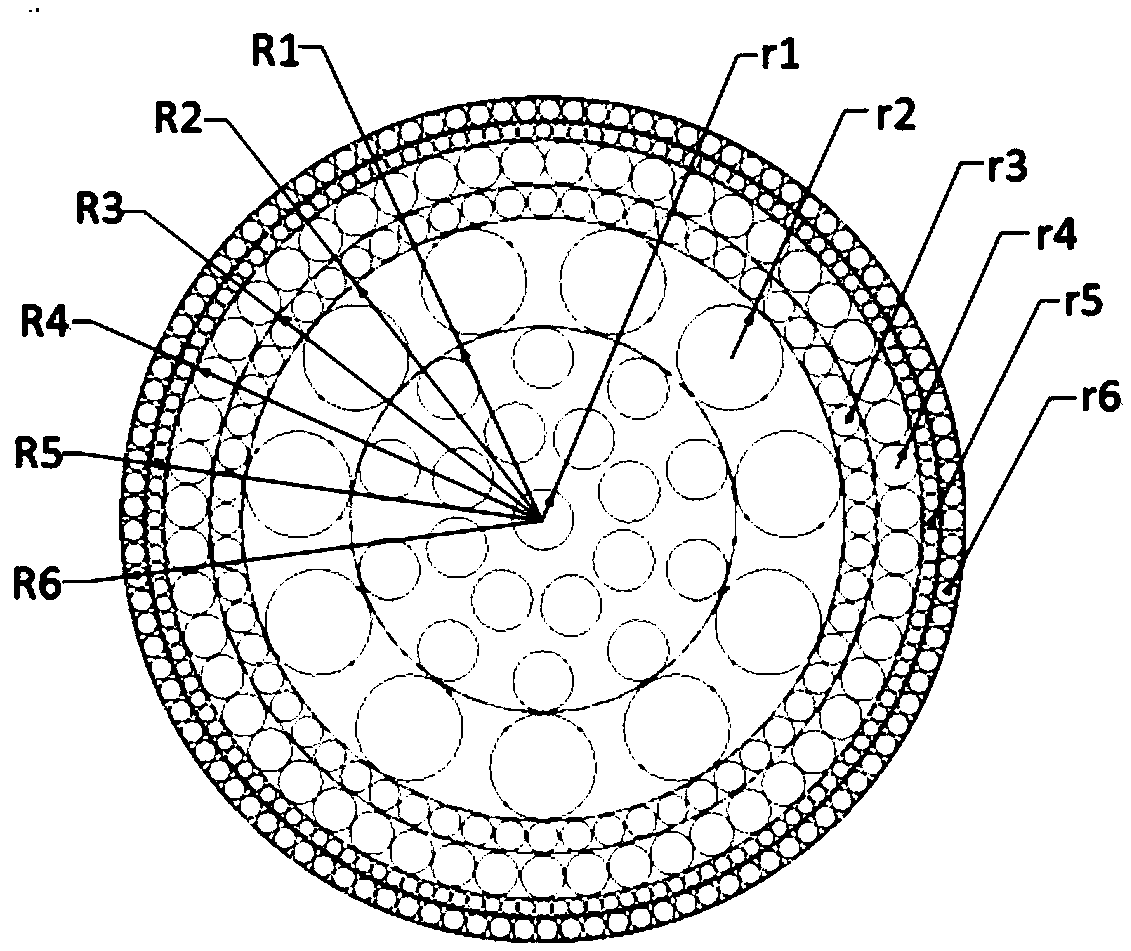

[0031] figure 1 It is a schematic structural diagram of a lens based on 3D printing in an embodiment of the present invention. like figure 1 As shown, the lens includes:

[0032]The cylindrical body 2 has a first radius and a first equivalent dielectric constant, wherein the cylindrical body 2 has a plurality of first through holes uniformly distributed through the upper and lower surfaces.

[0033] Further, the range of the first radius is 15-17mm; the first equivalent dielectric constant is 1.95; the radius of the first through hole is 2.5mm.

[0034] Specifically, the shape of the central cylindrical area 2 is a cylindrical structure, located at the center of the lens, and the central cylindrical area 2 and the lens have the same midline axis, and the central cylindrical area 2 The range of the first radius is 15-17mm. In this embodiment, the first radius R1=16mm is preferred, and the equivalent dielectric constant is 1.95. Wherein, the material of the central cylindrica...

Embodiment 2

[0051] An embodiment of the present invention also provides a lens antenna, including a feed antenna and the aforementioned lens, wherein the feed antenna is arranged parallel to the axis of the lens.

[0052] Specifically, place the feed antenna parallel to the axis of the lens antenna, take the antenna radiation surface at a distance of 44mm from the center of the lens, and use CST simulation software to perform simulation as an example. The simulation results show that the lens antenna has a greater impact on the feed antenna The effect of beam convergence is very obvious, and the maximum gain is increased by 10 dB. like Figure 5 As shown, it can be seen that its 3dB lobe width is 7.4°, such as Image 6 As shown, it can be seen that its 3dB lobe width is 10.6°, and the above results further show that the loaded lens antenna has a strong converging effect on the pattern of the feed antenna. Since the present invention has no special requirements for the feed antenna, as l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com