Plasticizer composition comprising cyclohexane 1,4-diester-based compound, and resin composition comprising same

A technology of resin composition and cyclohexane, which is applied in the field of plasticizer composition and resin composition containing the plasticizer composition, can solve the problems of harmfulness to human body, destruction of endocrine system environmental hormones, volatilization loss rate of processing performance, Migration loss rate thermal stability limitations and other issues, to achieve excellent stress resistance, excellent volatility resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Method for preparing plasticizer composition

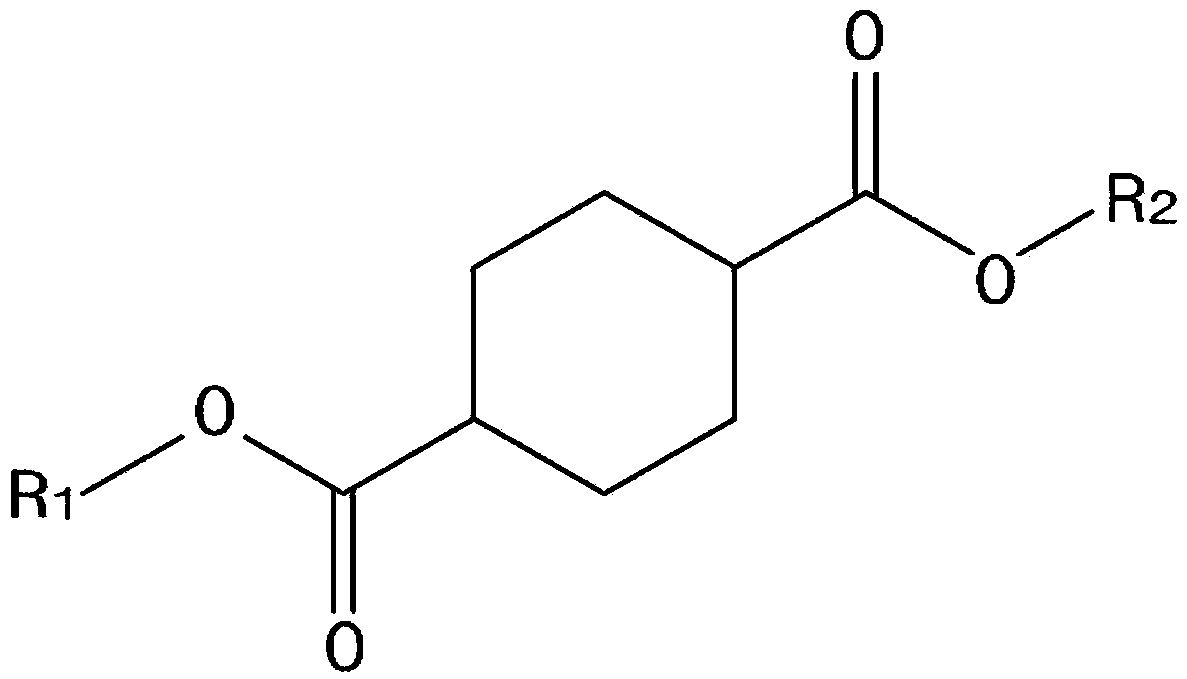

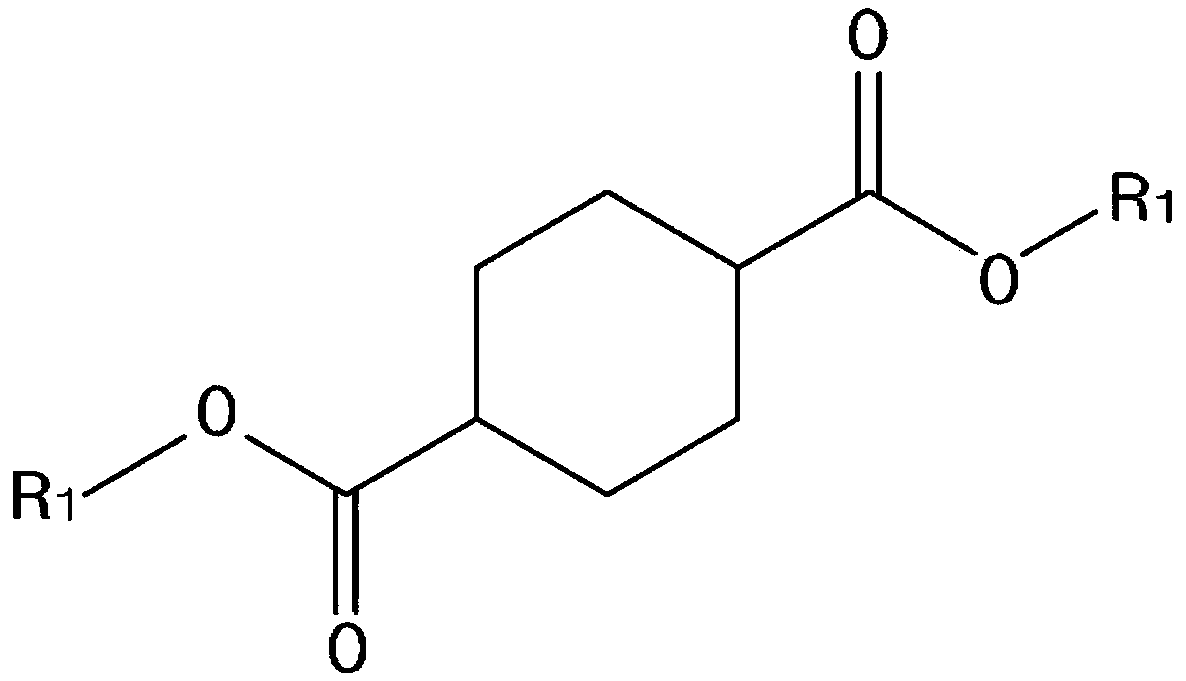

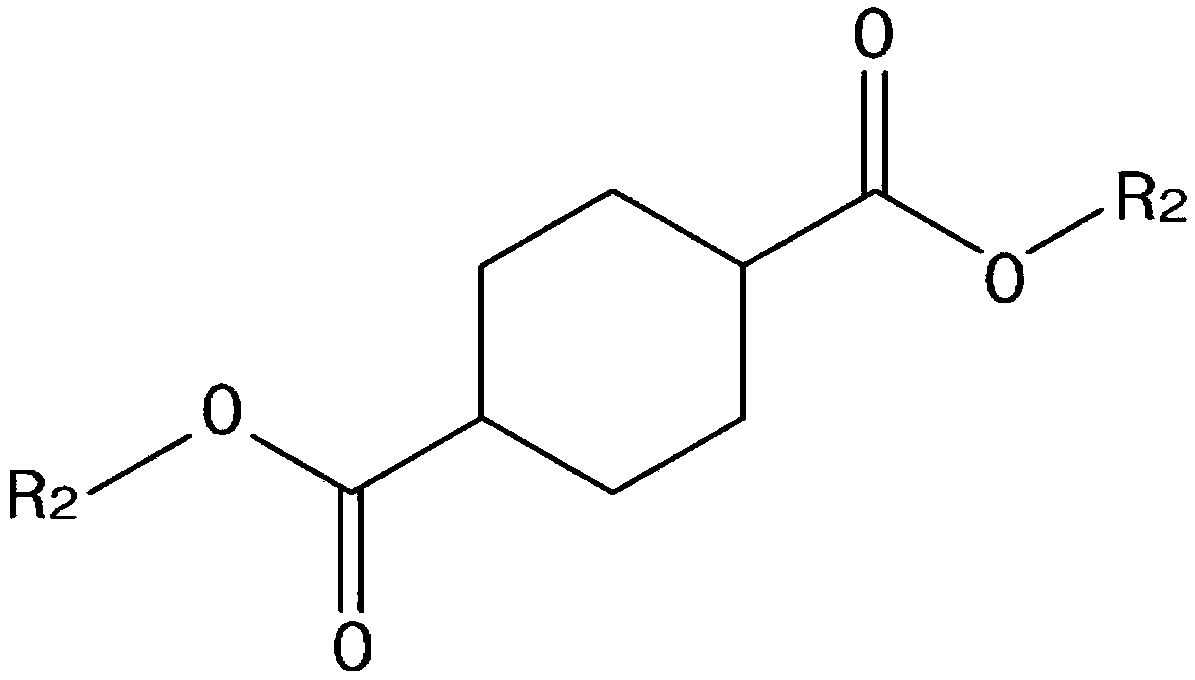

[0059] According to one embodiment of the present invention, there is provided a method for preparing a plasticizer composition, the preparation method comprising: preparing an ester composition by performing transesterification of a diester compound and an alcohol; The hydrogenation of the ester composition is carried out to prepare the cyclohexane 1,4-diester compound composition, wherein the diester compound includes bis(2-ethylhexyl) terephthalate (DEHTP ).

[0060] The preparation method of the plasticizer composition may include: preparing an ester composition in which three types of ester compounds are mixed by performing transesterification of the diester compound and alcohol.

[0061] The diester compound used as the reactant in the transesterification reaction can be bis(2-ethylhexyl) terephthalate, wherein, 2-ethylhexyl is ethyl and hexyl having 6 carbon atoms. - a carbon-bonded substituent at a position whic...

Embodiment 1

[0108] 1) Esterification

[0109] 2,000 g of bis(2-ethylhexyl) terephthalate (DEHTP) and 340 g (17 parts by weight relative to 100 parts by weight of DEHTP) were added to a reactor equipped with a stirrer, condenser and decanter ) of n-butanol, and then under a nitrogen atmosphere at a reaction temperature of 160 ° C for 2 hours of transesterification reaction to obtain dibutyl terephthalate (DBTP) containing 4% by weight, 35% by weight and 61% by weight ), butyl (2-ethylhexyl) terephthalate (BEHTP) and bis (2-ethylhexyl) terephthalate (DEHTP) ester plasticizer composition.

[0110] The ester plasticizer composition was subjected to mixed distillation to remove butanol and 2-ethylhexanol, thereby finally preparing a mixed composition.

[0111] 2) Hydrogenation

[0112] 1,000 g of the composition prepared by the above-mentioned esterification and 20 g of ruthenium catalyst (N.E CHEMCAT) were added to a 1.5 L high-pressure reactor as raw materials, and hydrogen gas was add...

Embodiment 2

[0114] 1) Esterification

[0115] Into a 3 L four-neck reactor equipped with a cooler, condenser, decanter, reflux pump, temperature controller, stirrer, etc., were added 498.0 g of purified terephthalic acid (PTA), 585 g of 2-ethyl Hexanol (2-EH) (molar ratio PTA:2-EH=1.0:1.5) and 333 g of butanol (BA) (molar ratio PTA:BA=1.0:1.5). 10 g (2.0 parts by weight relative to 100 parts by weight of PTA) of a sulfonic acid-based catalyst (methanesulfonic acid (MSA)) was added thereto, and then the temperature of the reactor was slowly raised to about 150°C. Water generation started at about 130°C, and the esterification reaction was carried out under atmospheric pressure at a final reaction temperature of about 220°C for about 4.5 hours while continuously introducing nitrogen, and was terminated when the acid value reached 6.0.

[0116] After the reaction is over, distillation extraction is carried out under reduced pressure for 0.5 hours to 4 hours to remove unreacted raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com