Paper coating material having environment-friendly, water-proof and oil-proof properties, and method of manufacturing the same

A technology of coating material and aqueous solution, which is applied in the field of paper coating materials and its preparation, can solve the problems of undeveloped environmental protection paper coating materials, achieve the effects of eliminating chemical odor, low preparation cost, and excellent copolymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Example 1. Preparation of a paper coating material comprising polyvinyl alcohol and copolymerized therein to obtain a copolymer emulsion of a silicon-based polymer and an acrylic polymer

[0103] While maintaining the temperature of the reactor containing 120 g of deionized water at 60° C., 40 g of methyl methacrylate, 44 g of butyl acrylate, 1.0 g of methacrylic acid and 1.0 g of hydroxyethyl methacrylate were added to the reactor. Blended acrylic monomer mixture. To this was added 0.2 g ammonium persulfate, 0.4 g dibutyltin dilaurate (DBTDL), 1.0 g octylphenol ethoxylate (OP), 0.8 g sodium dodecyl sulfate (SDS) and 0.2 g Na 2 CO 3 .

[0104] When the temperature of the reactor reached 80°C, ammonium persulfate was added. After 10 minutes, the silicon-based monomer was introduced into the reactor at a uniform rate over 2 hours. The amount of the silicon-based monomer is controlled so that the weight ratio of the acrylic polymer to the silicon-based polymer in the c...

Embodiment 2

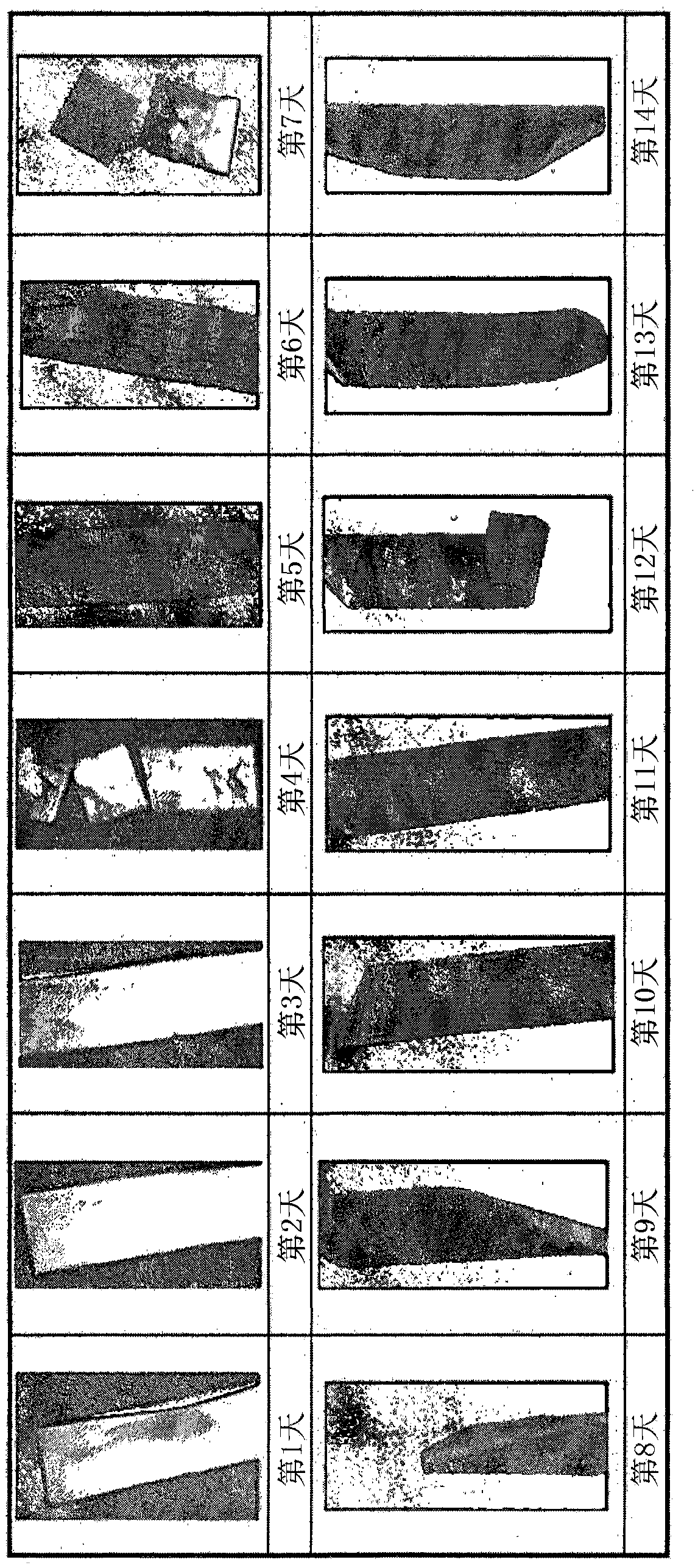

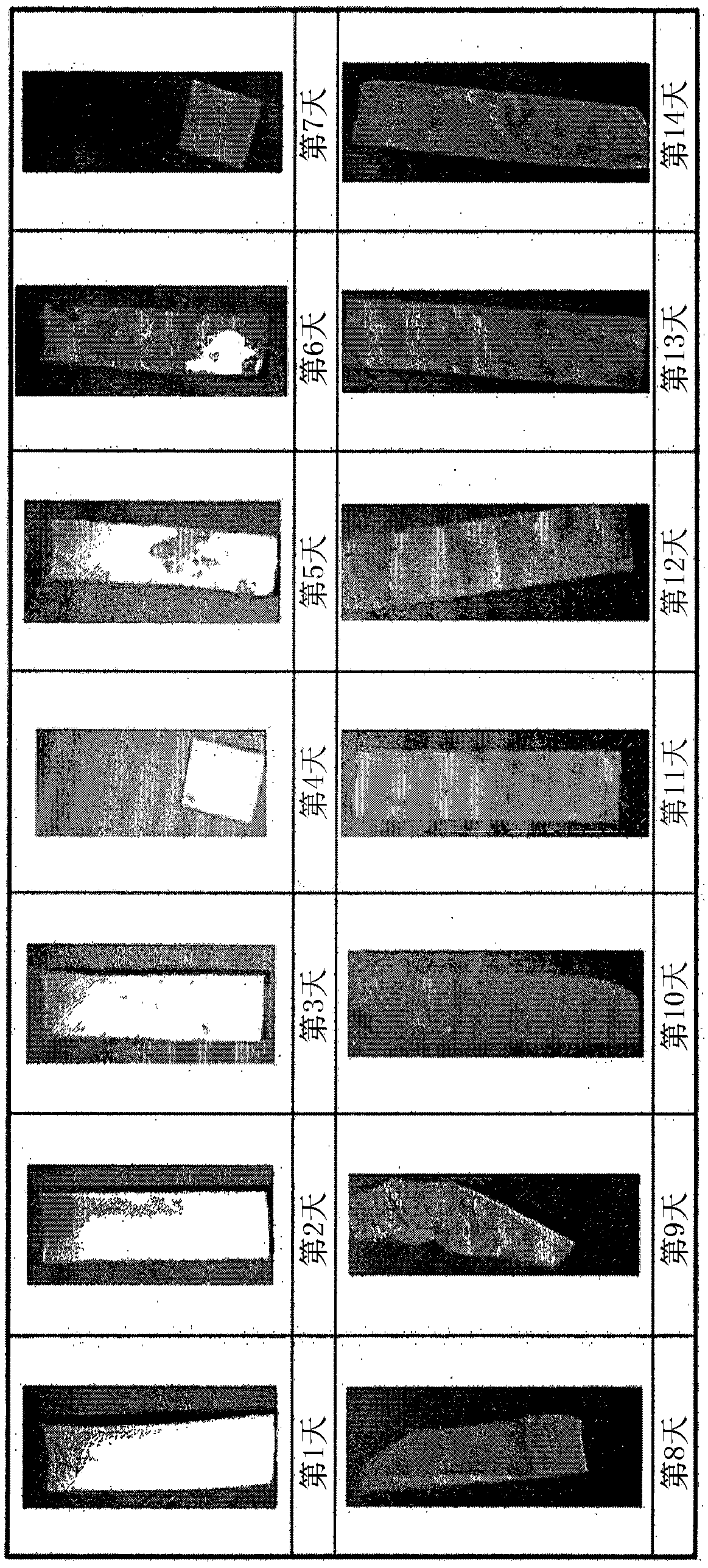

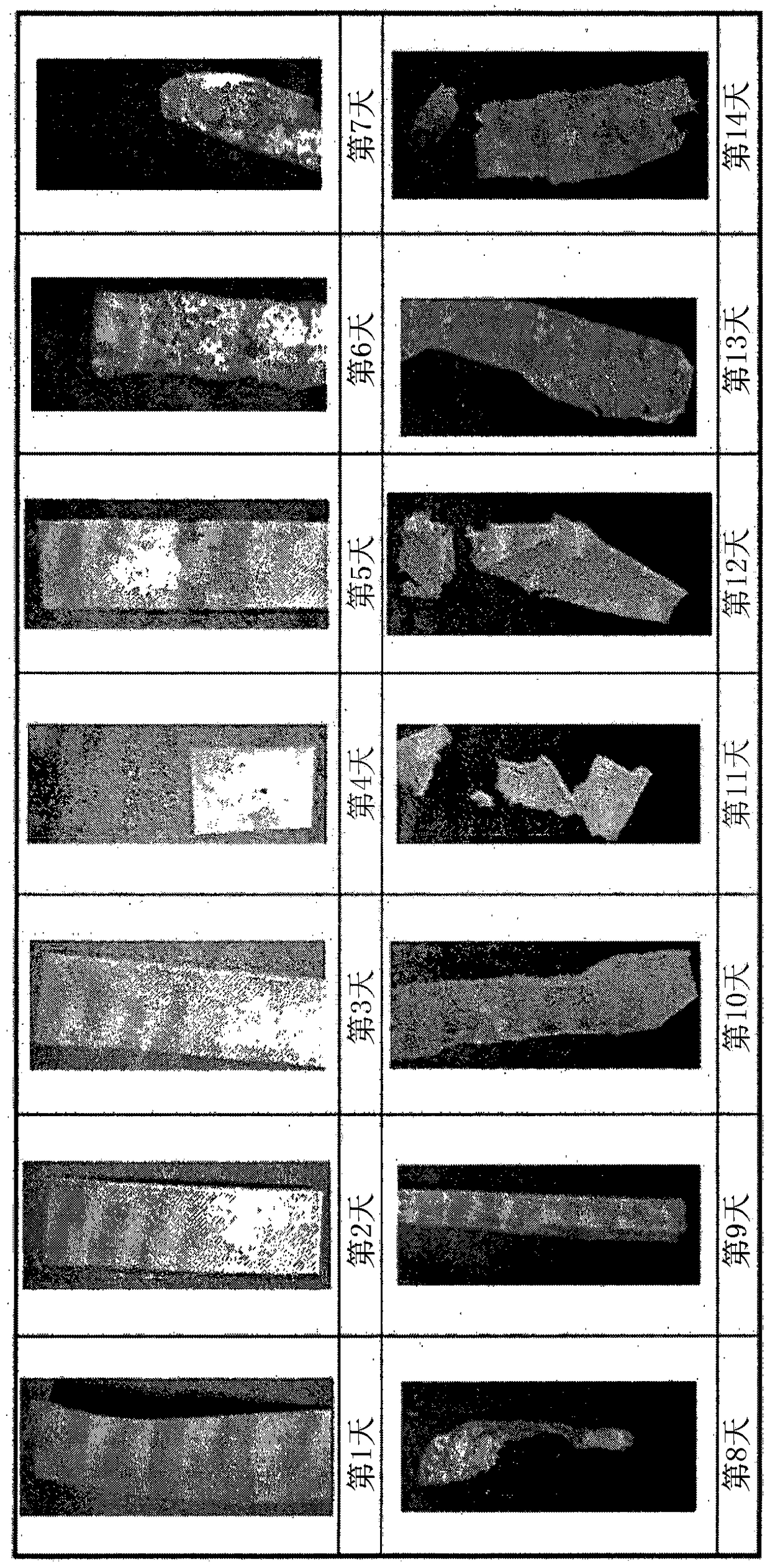

[0107] Embodiment 2. The preparation of coating material and the coating of base paper for cups

[0108] Packaging paper was coated with the paper coating material prepared according to the preparation method of Example 1. Base paper for cups manufactured by Hansol Paper Co., Ltd. (trade name: FAB350, basis weight: 350g / m 2 ). Using a water-soluble coating solution in which 35.0% by weight of the paper coating material of the present invention, 0.2% by weight of silicon dioxide, and 64.8% by weight of water were mixed, the coating was carried out at 9.5 g / m using an air knife coating device. 2 One side coating is performed.

Embodiment 3

[0109] Example 3. Coating of Base Paper for Cups

[0110] Using the same cup base paper and coating solution as in Example 2, using a rod coating device at 8.5g / m 2 One side coating is performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com