Ion strain sensor and preparation method and application thereof

A strain sensor, ion technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, microstructure devices composed of deformable elements, etc., can solve conformal integration Difficulty, low sensitivity and other issues, to achieve the effect of low power consumption, high resolution, high spatial responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

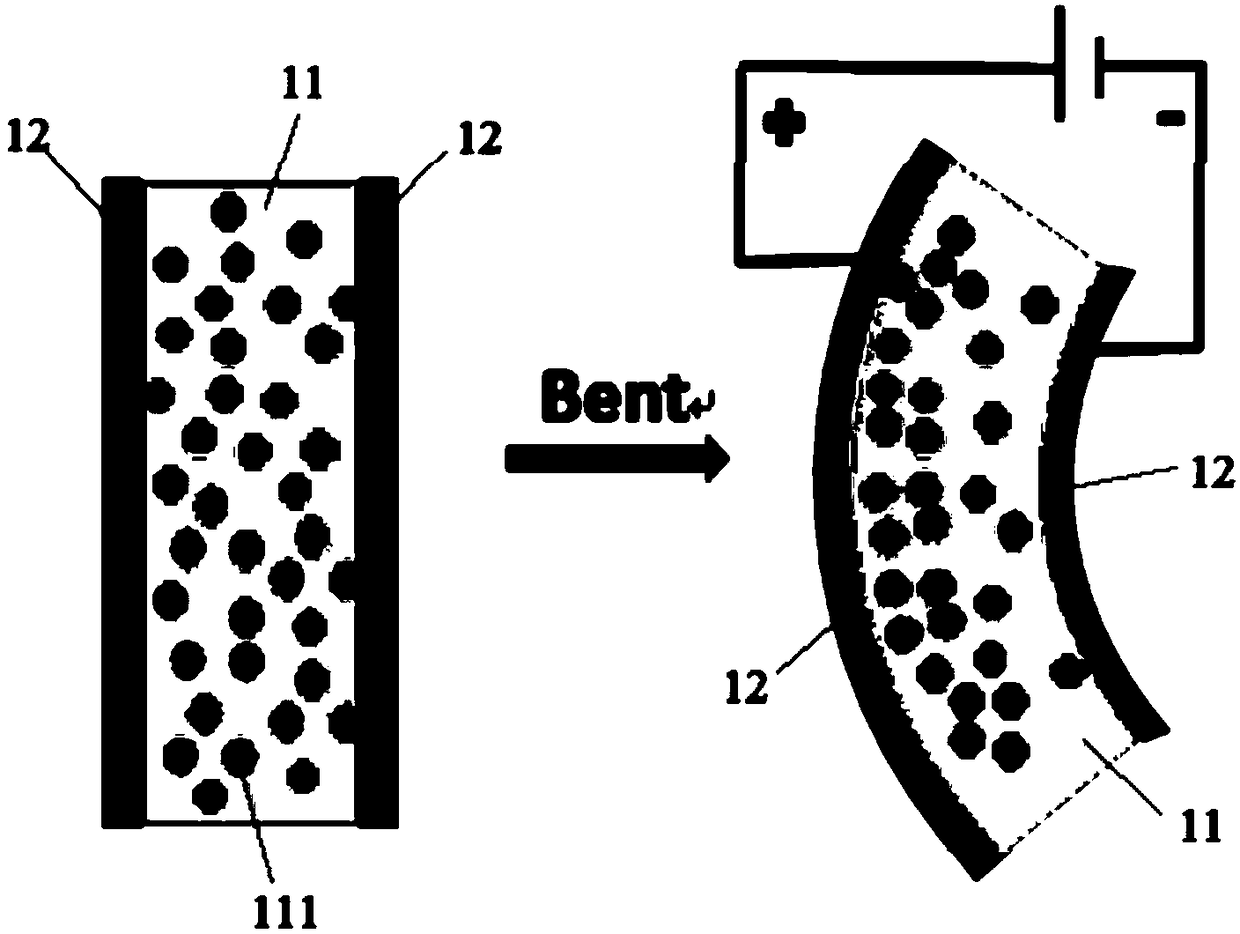

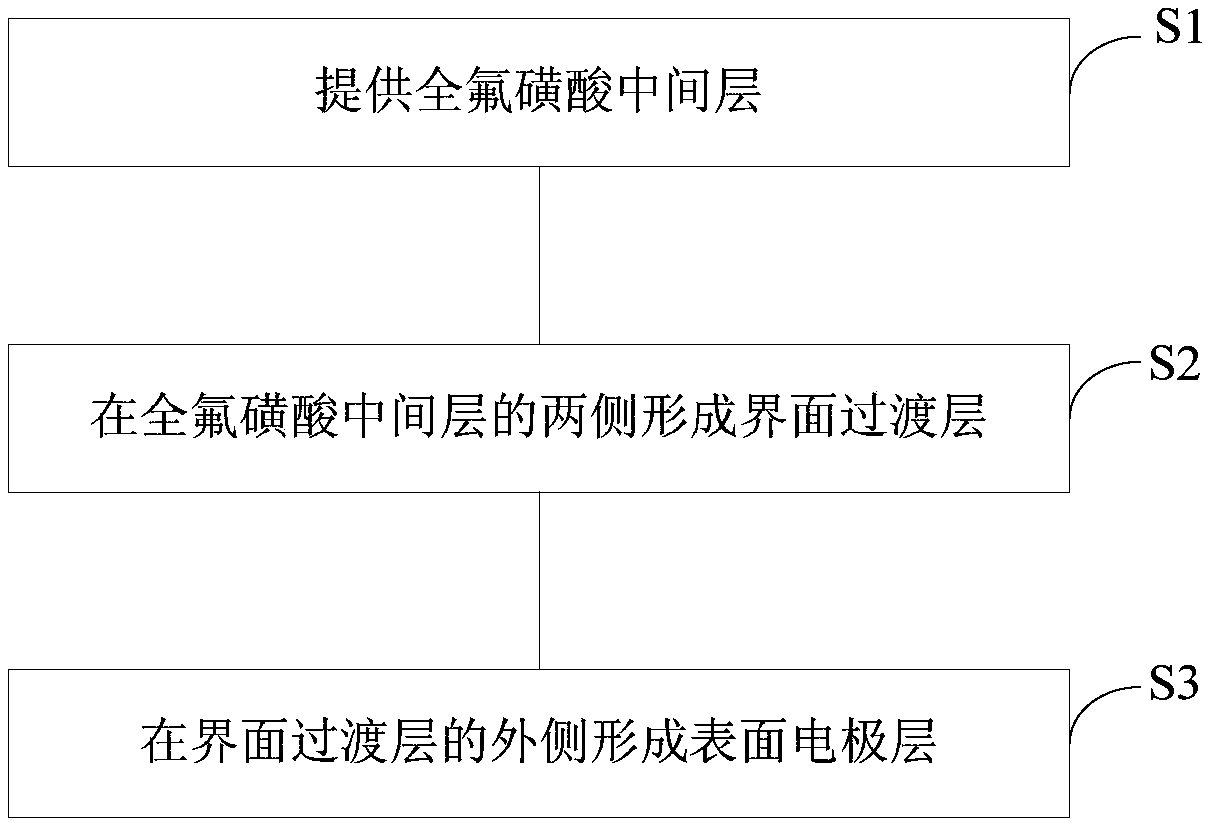

[0056] ginseng figure 2 As shown, the present invention also discloses a preparation method of an ion strain sensor, comprising:

[0057] S1. Provide a perfluorosulfonic acid intermediate layer;

[0058] S2, forming an interfacial transition layer on both sides of the perfluorosulfonic acid intermediate layer;

[0059] S3, forming a surface electrode layer outside the interface transition layer.

[0060] Preferably, step S1 is specifically:

[0061] Provide Nafion-117 membrane; or,

[0062] Through the liquid-phase film casting method, the polymer and the ionic liquid are dissolved in an organic solvent to form a uniform solution, which is poured into a glass slide and dried to obtain a perfluorosulfonic acid intermediate layer.

[0063] Preferably, step S2 is specifically:

[0064] Roughening the perfluorosulfonic acid interlayer by plasma etching or grinding;

[0065] The interfacial transition layer is formed on both sides of the perfluorosulfonic acid intermediate lay...

Embodiment 1

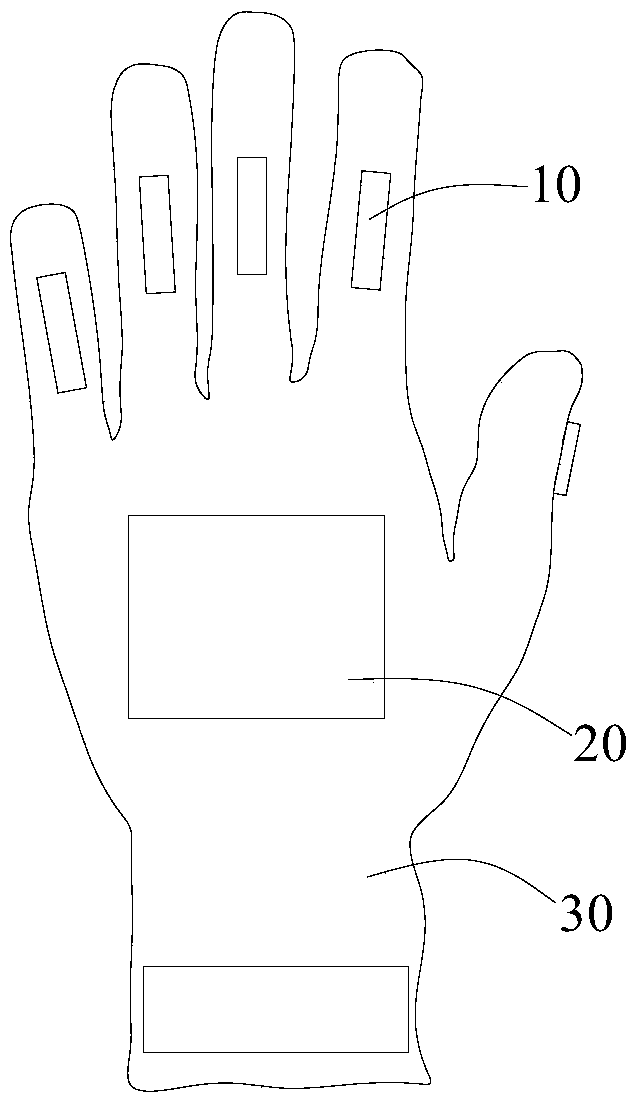

[0094] In this embodiment, an ion strain sensor and an intelligent Braille recognition glove using it are taken as an example for illustration.

[0095] The ionic strain sensor uses 1200-grit sandpaper to roughen the polyelectrolyte film and then pre-treat it. The electrodes were then prepared by a cyclic impregnation reduction method.

[0096] The specific preparation method is:

[0097] Immerse it in [Au(Phen)Cl 2 ]Cl solution, take it out after soaking for 24h, and rinse with deionized water;

[0098] Then put it into a beaker filled with deionized water and put it in a water bath at 60°C, and then drop 5% Na by mass fraction into the beaker 2 SO 3 The solution completes the reduction process;

[0099] Dilute H with 0.5mol / L at 75°C 2 SO 4 Washing with solution and deionized water to remove Na+ ions that may be introduced during impregnation / reduction;

[0100] The prepared sensor film was clamped flat and fixed between two glass slides, and heated at 140°C for 2 ho...

Embodiment 2

[0111] In this embodiment, the ion strain sensor and the smart sign language recognition glove using it are taken as an example for illustration.

[0112] In the ion strain sensor, the surface electrode layer is prepared by vacuum filtration.

[0113] The specific preparation method is:

[0114] Weigh 4.5g TPU, 0.9g EMITFSI dissolved in 30mL DMAC, stir magnetically for 24 hours to obtain a uniform dispersion, take 3ml of the uniform dispersion and inject it on a glass slide, and dry it on a heating platform at 60°C to obtain a perfluorosulfonic acid interlayer;

[0115]Weigh 3 mg of silver nanowires and disperse them in water, then weigh porous graphene and carbon tubes with a molar ratio of 1:0 to prepare an NMP dispersion, the concentration of porous graphene is 1.3 mg / mL, and ultrasonicate for 30 minutes in an ice bath;

[0116] Deposit silver nanowires and porous graphene / carbon tube layers on PVDF filter paper layer by layer, and then dry on a heating platform at 40°C to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com