Modified aluminum polychlorid for sewage treatment and preparation method thereof

A polyaluminum chloride and sewage treatment technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of poor removal effect of heavy metal ions, polyaluminum chloride Flocculation ability is limited and other problems, to achieve good adsorption, increase flocculation ability, improve the effect of flocculation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

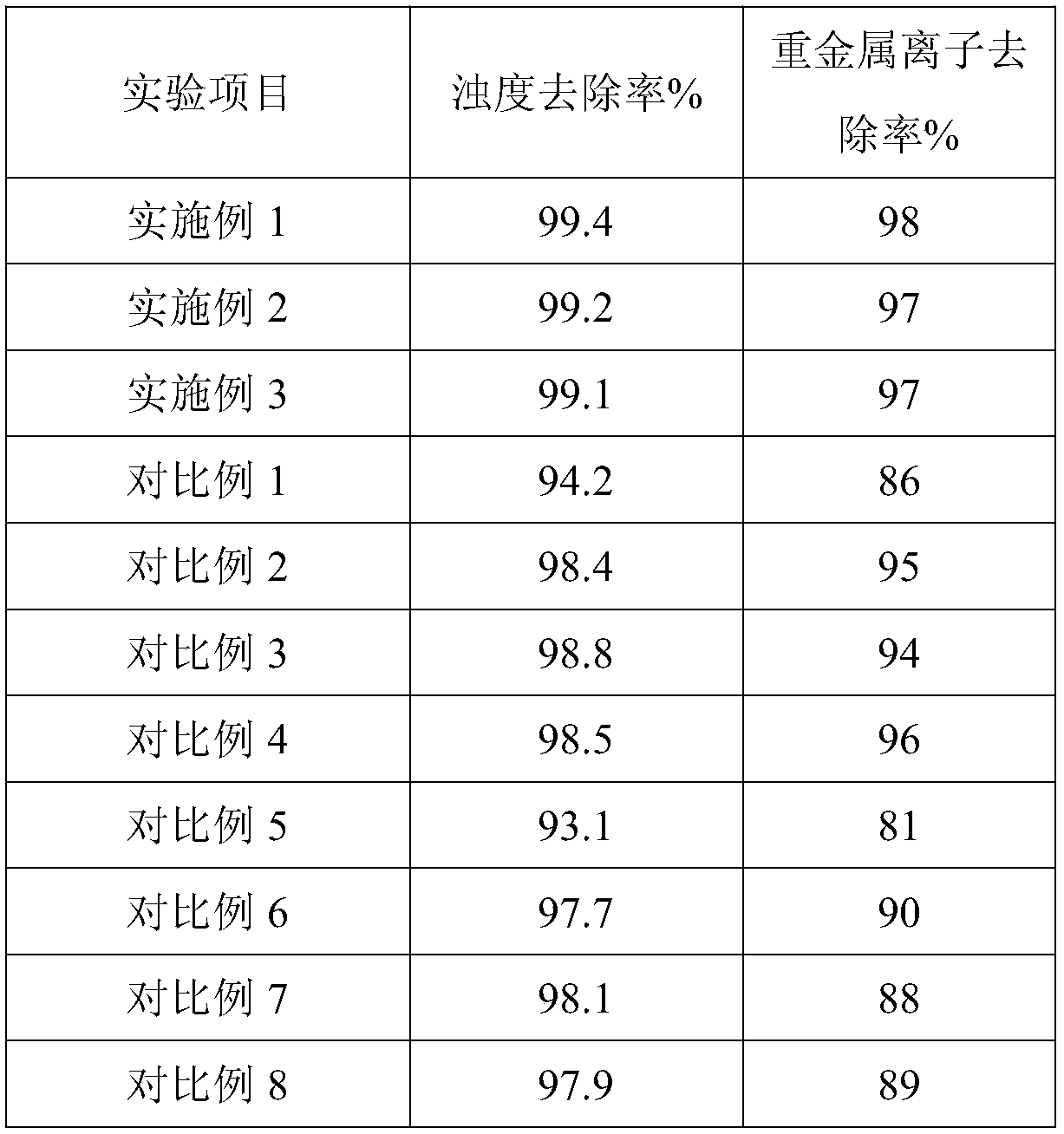

Examples

preparation example Construction

[0023] A method for preparing the above-mentioned improved polyaluminum chloride for sewage treatment, comprising the following steps: (1) putting hydrochloric acid in the reactor, adding bauxite at the same time, reacting for 10-20min, and then supplementally heating the reactor to 95- React at 105°C for 3-5 hours, add sodium chlorate and keep warm for 2-4 hours, collect the polyaluminum chloride body by precipitation or filtration; (2) mix the polyaluminum chloride body, industrial salt, soda powder, and hydroxyethyl cellulose Sufficiently mix the element, corn oligopeptide powder and polyether modified organosiloxane, and grind to 200 mesh or more.

[0024] The consumption of described bauxite is 15-20% of hydrochloric acid. The concentration of the hydrochloric acid is 20-30%.

Embodiment 1

[0027] An improved polyaluminum chloride for sewage treatment, comprising the following raw materials: 49 parts of polyaluminum chloride body, 23 parts of sodium chlorate, 11.5 parts of industrial salt, 16 parts of soda powder, 13 parts of hydroxyethyl cellulose, corn 6 parts of oligopeptide powder and 3 parts of polyether modified organosiloxane.

[0028] A method for preparing the above-mentioned improved polyaluminum chloride for sewage treatment, comprising the following steps: (1) putting hydrochloric acid in the reactor, adding bauxite at the same time, reacting for 15 minutes, and then supplementally heating the reactor to 100°C for reaction 4 hour, add sodium chlorate and continue to insulate for 3 hours, collect the polyaluminum chloride body through precipitation; The modified organosiloxane is fully mixed and ground to more than 200 mesh.

[0029] The consumption of described bauxite is 17.5% of hydrochloric acid. The concentration of the hydrochloric acid is 25%....

Embodiment 2

[0031] An improved polyaluminum chloride for sewage treatment, comprising the following raw materials: 42 parts of polyaluminum chloride body, 26 parts of sodium chlorate, 10 parts of industrial salt, 19 parts of soda powder, 10 parts of hydroxyethyl cellulose, corn 8 parts of oligopeptide powder and 2 parts of polyether modified organosiloxane.

[0032] A method for preparing the above-mentioned improved polyaluminum chloride for sewage treatment, comprising the following steps: (1) putting hydrochloric acid in the reactor, adding bauxite at the same time, reacting for 20 minutes, and then supplementally heating the reactor to 95°C for 5 minutes hour, add sodium chlorate and continue to insulate for 2 hours, collect the polyaluminum chloride body through filtration; The modified organosiloxane is fully mixed and ground to more than 200 mesh.

[0033] The consumption of described bauxite is 15% of hydrochloric acid. The concentration of the hydrochloric acid is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com