Modified urea-formaldehyde glue and preparation method thereof

A technology for modifying urea-formaldehyde and formaldehyde, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc. It can solve the problems of low free formaldehyde content, no antibacterial effect of urea-formaldehyde adhesives, and unfavorable promotion. The ability to kill microorganisms, good physical and mechanical properties, and the effect of reducing the amount of formaldehyde released

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

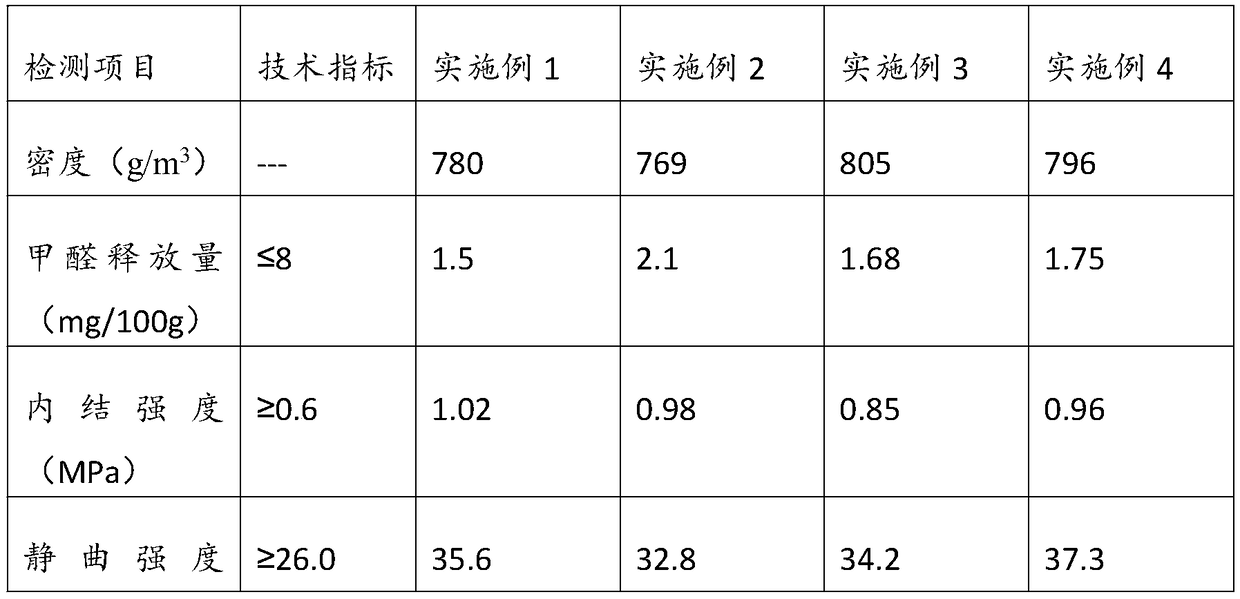

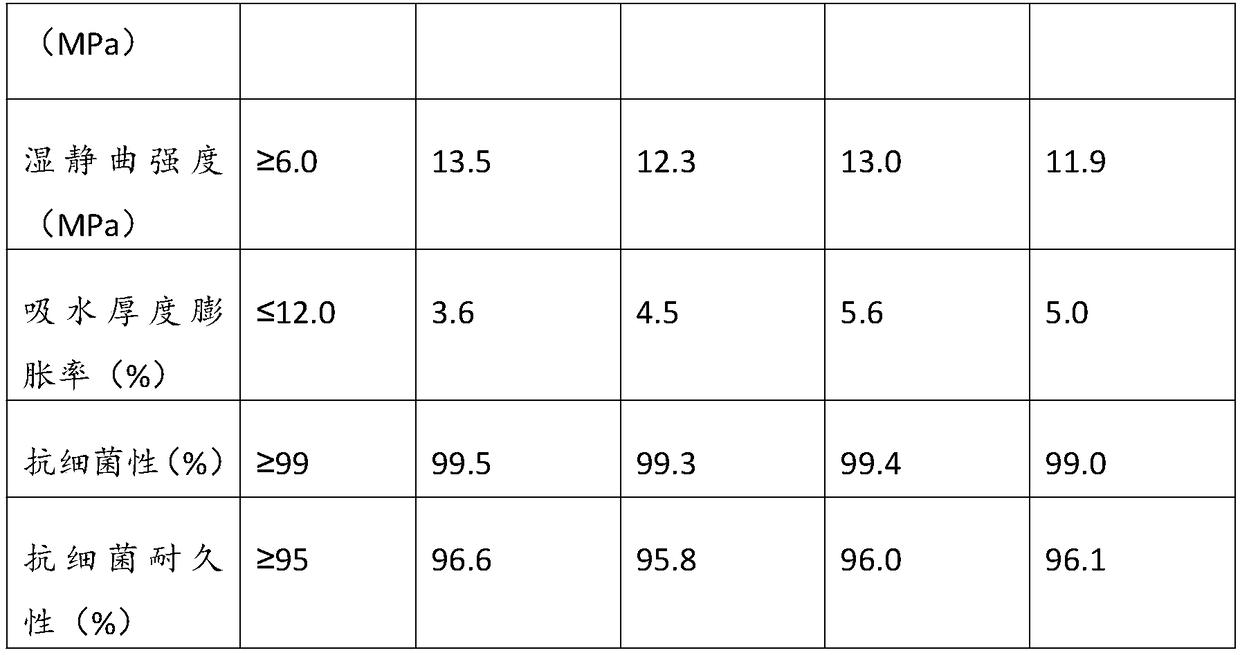

Examples

Embodiment 1

[0028] A modified urea-formaldehyde glue, comprising the following raw materials in parts by weight: 90 parts of formaldehyde solution with a mass concentration of 35%, 40 parts of urea, 1 part of melamine, an appropriate amount of liquid caustic soda with a mass concentration of 30%, an appropriate amount of formic acid, and 0.2 parts of borax 1 part, 0.05 part of antibacterial agent, 3 parts of hollow silica submicron spheres and 2 parts of water-based fluorine-modified phosphorus-containing acrylate emulsion.

[0029] Among them, the antibacterial agent is composed of polyhexamethyleneguanidine phosphate and polyhexamethyleneguanidine hydrochloride with a mass ratio of 1:3; the diameter of the hollow silica submicron sphere is 300nm, and the shell thickness is 40nm. The shell layer has a mesoporous structure, the average pore diameter of the mesopores is 3nm, and the specific surface area of the hollow silica submicron sphere is 100m 2 / g.

[0030] The preparation method...

Embodiment 2

[0037] A modified urea-formaldehyde glue, comprising the following raw materials in parts by weight: 80 parts of formaldehyde solution with a mass concentration of 40%, 30 parts of urea, 0.2 part of melamine, an appropriate amount of liquid caustic soda with a mass concentration of 25%, an appropriate amount of formic acid, and 0.1 parts of borax 1 part, 0.01 part of antibacterial agent, 1 part of hollow silica submicron sphere and 1 part of aqueous fluorine-modified phosphorus-containing acrylate emulsion.

[0038] Among them, the antibacterial agent is composed of polyhexamethyleneguanidine phosphate and polyhexamethyleneguanidine hydrochloride with a mass ratio of 1:2; the diameter of the hollow silica submicron sphere is 100nm, and the shell thickness is 20nm. The shell layer has a mesoporous structure, the average pore diameter of the mesopores is 1nm, and the specific surface area of the hollow silica submicron sphere is 80m 2 / g.

[0039] The preparation method of ab...

Embodiment 3

[0046] A modified urea-formaldehyde glue, comprising the following raw materials in parts by weight: 100 parts of formaldehyde solution with a mass concentration of 35%, 50 parts of urea, 3 parts of melamine, an appropriate amount of liquid caustic soda with a mass concentration of 35%, an appropriate amount of formic acid, and 0.3 parts of borax 1 part, 0.1 part of antibacterial agent, 5 parts of hollow silica submicron spheres and 5 parts of aqueous fluorine-modified phosphorus-containing acrylate emulsion.

[0047] Among them, the antibacterial agent is composed of polyhexamethyleneguanidine phosphate and polyhexamethyleneguanidine hydrochloride with a mass ratio of 1:4; the diameter of the hollow silica submicron sphere is 400nm, and the shell thickness is 50nm. The shell layer has a mesoporous structure, the average pore diameter of the mesopores is 5nm, and the specific surface area of the hollow silica submicron sphere is 150m 2 / g.

[0048] The preparation method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com