A functional separator for lithium sulfide battery and a preparation method thereof

A lithium-sulfur battery, functional technology, applied in battery components, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of lithium-sulfur battery volume expansion effect, battery electrochemical performance instability, etc. Achieve the effects of promoting fast migration, good electronic conductivity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

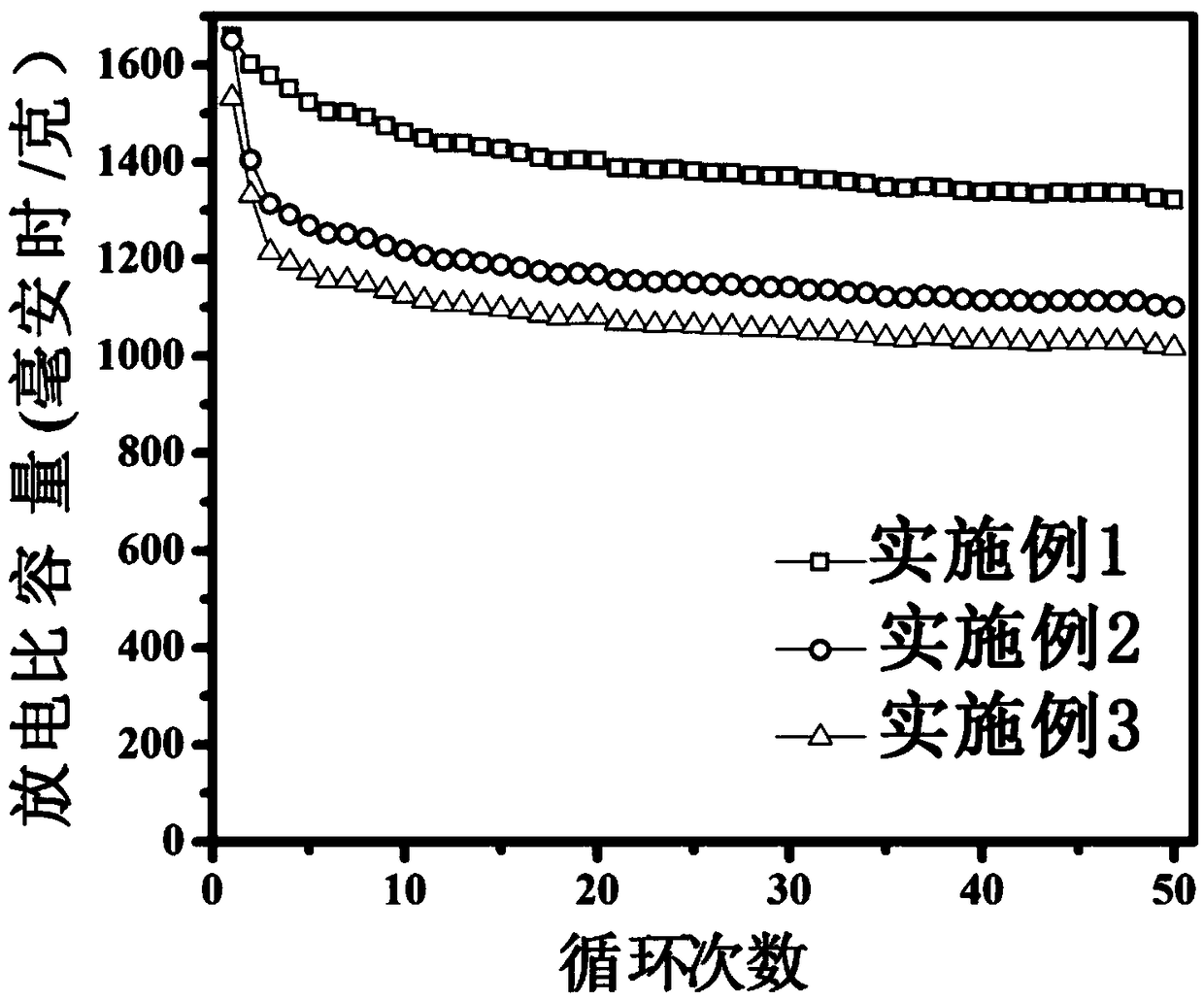

Embodiment 1

[0034] The raw materials of the functional separator for lithium-sulfur batteries include cobalt-molybdenum sulfide solid solution and graphene.

[0035] The mass ratio of the cobalt molybdenum sulfide solid solution to graphene is 2:1.

[0036] The preparation method of the functional separator for lithium-sulfur battery comprises the following steps:

[0037] (1) Preparation of cobalt-molybdenum sulfide solid solution: mix 1.5g sodium molybdate with cobalt nitrate and thioacetamide according to molar

[0038] Dissolve in 200mL deionized water at a ratio of 1:1:4 to obtain a mixed solution, place the mixed solution in a water bath, heat and stir, and keep warm for 15 minutes when the temperature rises to 90°C; add 15mL of absolute ethanol, and then add 15mL Hydrochloric acid with a concentration of 9mol / L, after the solution is naturally cooled to room temperature, the precipitated product is collected, the precipitated product is repeatedly washed three times with deionized...

Embodiment 2

[0045] The raw materials of the functional separator for lithium-sulfur batteries include cobalt-molybdenum sulfide solid solution and graphene.

[0046] The mass ratio of the cobalt molybdenum sulfide solid solution to graphene is 3:1.

[0047] The preparation method of the functional separator for lithium-sulfur battery comprises the following steps:

[0048] (1) Preparation of cobalt-molybdenum sulfide solid solution: mix 1g of sodium molybdate with cobalt nitrate and thioacetamide according to the molar ratio

[0049] Dissolve in 100mL deionized water at a ratio of 1:1:3 to obtain a mixed solution, place the mixed solution in a water bath, heat and stir, and keep warm for 10 minutes when the temperature rises to 80°C; add 10mL of absolute ethanol, and then add 10mL of concentration It is 8mol / L hydrochloric acid. After the solution is naturally cooled to room temperature, the precipitated product is collected. The precipitated product is washed three times repeatedly with...

Embodiment 3

[0054] The raw materials of the functional separator for lithium-sulfur batteries include cobalt-molybdenum sulfide solid solution and graphene.

[0055] The mass ratio of the cobalt molybdenum sulfide solid solution to graphene is 1:1.

[0056] The preparation method of the functional separator for lithium-sulfur battery comprises the following steps:

[0057] (1) Preparation of cobalt-molybdenum sulfide solid solution: mix 2g of sodium molybdate with cobalt nitrate and thioacetamide according to the molar ratio

[0058] Dissolve in 300mL deionized water at a ratio of 1:1:5 to obtain a mixed solution, place the mixed solution in a water bath, heat and stir, and keep warm for 20 minutes when the temperature rises to 100°C; add 20mL of absolute ethanol, and then add 20mL of concentration It is 10mol / L hydrochloric acid. After the solution is naturally cooled to room temperature, the precipitated product is collected. The precipitated product is repeatedly washed three times wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com