Polycarbonyl compound modified graphene oxide for lithium battery electrode material and preparation method thereof

A compound and polycarbonyl technology, applied in the field of polycarbonyl compound-modified graphene oxide and its preparation, can solve the problems of cumbersome synthesis methods and general performance of lithium-ion battery cathode materials, and achieve high specific capacity, excellent cycle stability, The effect of the simple process of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

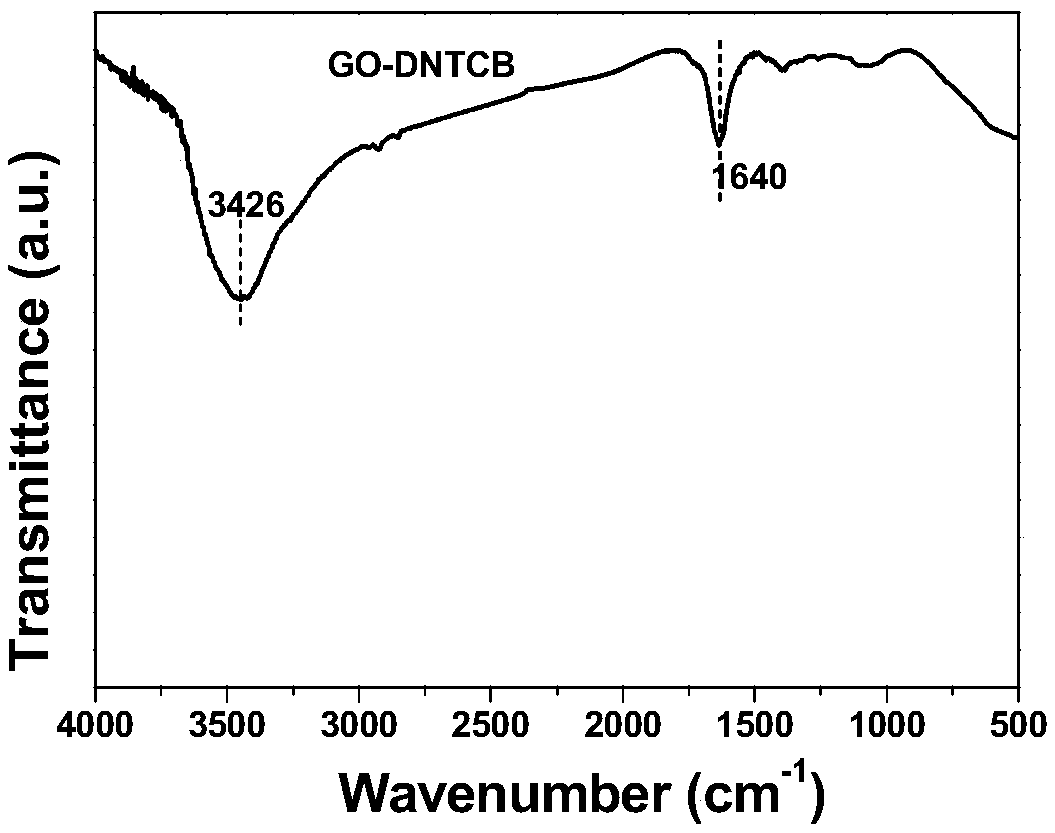

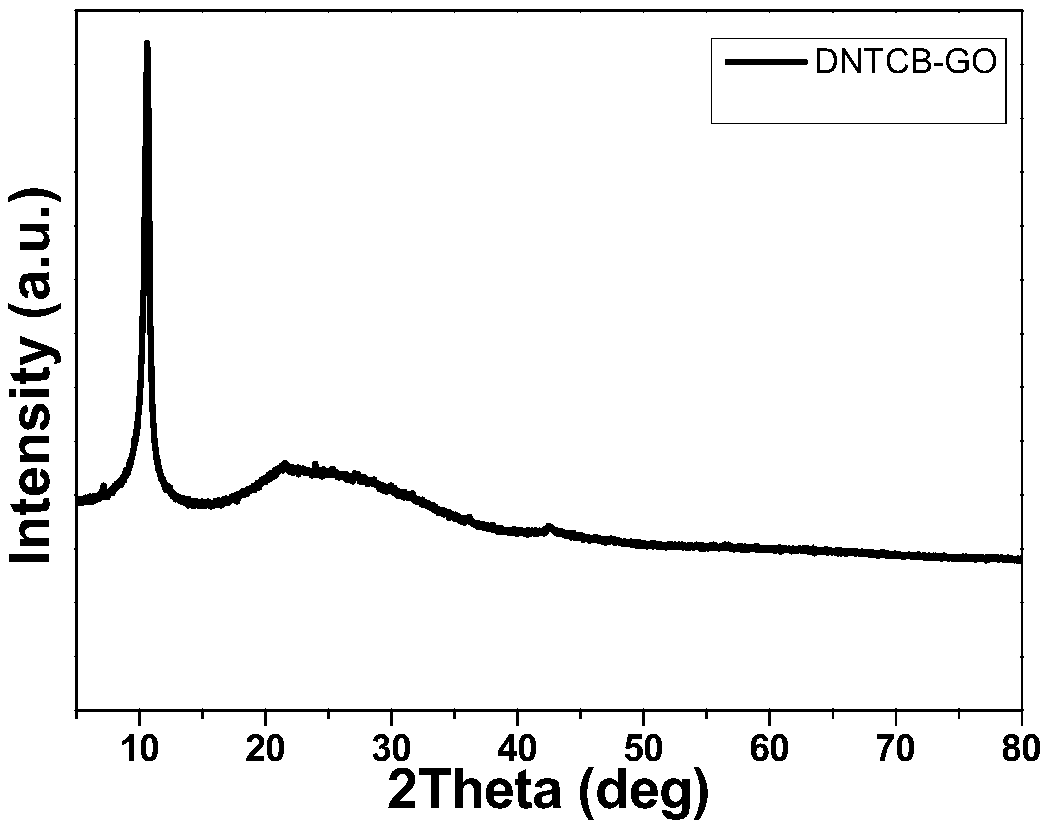

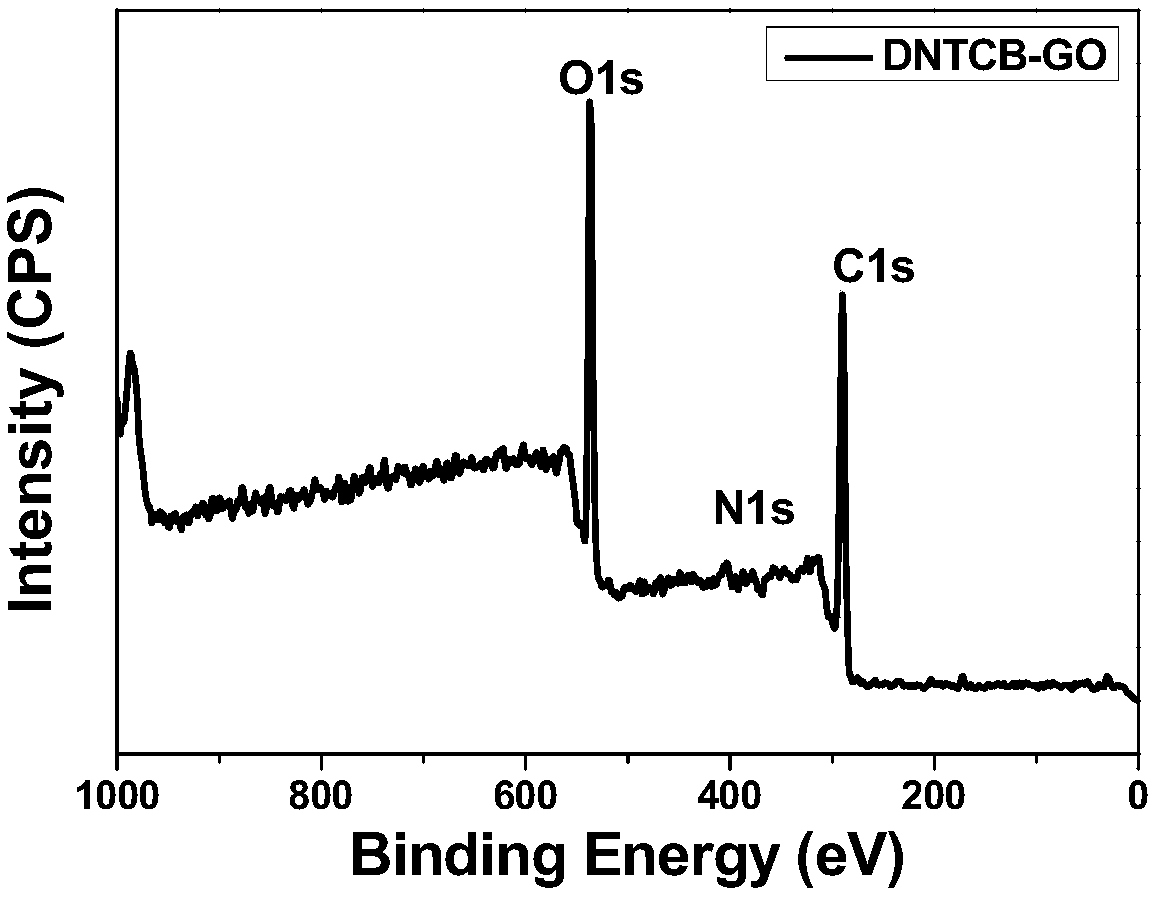

[0039] Weigh 24mg of N,N'-diamino-1,4,5,8-naphthalimide (DNTCB) and 60mg of graphene oxide (GO) into a 25mL small beaker, add 20mL of anhydrous N,N' - Dimethylformamide (DMF), sonication for 20 minutes. Then add the suspension into a 250mL three-necked flask, add 40mL of anhydrous DMF, then add 24mg of dicyclohexylcarbodiimide (DCC), then turn on the magnetic stirring, stir until uniformly dispersed, and heat the reaction to 60°C, React for 24 hours. After the reaction was over, the heating was stopped and the oil bath was removed to obtain a dark brown suspension. After the suspension was cooled to room temperature, it was filtered with suction and washed several times with absolute ethanol to obtain a dark brown powder. The powder was placed in a petri dish and dried under vacuum at 50°C to obtain material A / DNTCB-GO. Infrared spectra( figure 1 ), powder X-ray diffraction pattern ( figure 2 ), photoelectron spectrum ( image 3 ), Raman spectrum ( Figure 4 ) indicate...

Embodiment 2

[0041] The experimental method is the same as that in Example 1, except that 24mg N,N'-diamino-1,4,5,8-naphthalimide (DNTCB) is changed to 9.5mg 2,6-diaminoanthraquinone, 24mg bicyclic Hexylcarbodiimide (DCC) was changed to 19.5 mg of dicyclohexylcarbodiimide (DCC), and material B / DAAQ-GO was obtained. Infrared spectra( Figure 12 ), powder X-ray diffraction pattern ( Figure 13 ), photoelectron spectrum ( Figure 14 ) shows that the synthesized product is compound A / DNTCB-GO. thermogravimetric map ( Figure 15 ) shows the thermal stability of the material; SEM image ( Figure 16 ) and TEM image ( Figure 17 ) shows that material B / DAAQ-GO is composed of layered nanosheets. from Figure 18 In the cyclic voltammogram, it can be seen that the shape of the spectrum after the third cycle is similar, indicating that the electrode material has good reversibility. from Figure 19 It can be seen from the charge-discharge diagram of the electrode material that the specific cap...

Embodiment 3

[0043] The experimental method is the same as that in Example 1, except that 60 mL of N,N'-dimethylformamide is changed to 60 mL of dimethyl sulfoxide (DMSO) to obtain material A / DNTCB-GO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com