Surface modified metal-organic framework compound, and preparation method and application thereof

A metal-organic framework and surface modification technology, which is applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, and separation methods, can solve problems such as poor water stability, and achieve reduced adhesion, good application prospects, and excellent water quality. The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 Based on octadecylamine (OA) surface-modified metal-organic framework composite

[0043] (1) Metal-organic framework composite (ZIF-67-OA composite) based on surface modification of octadecylamine

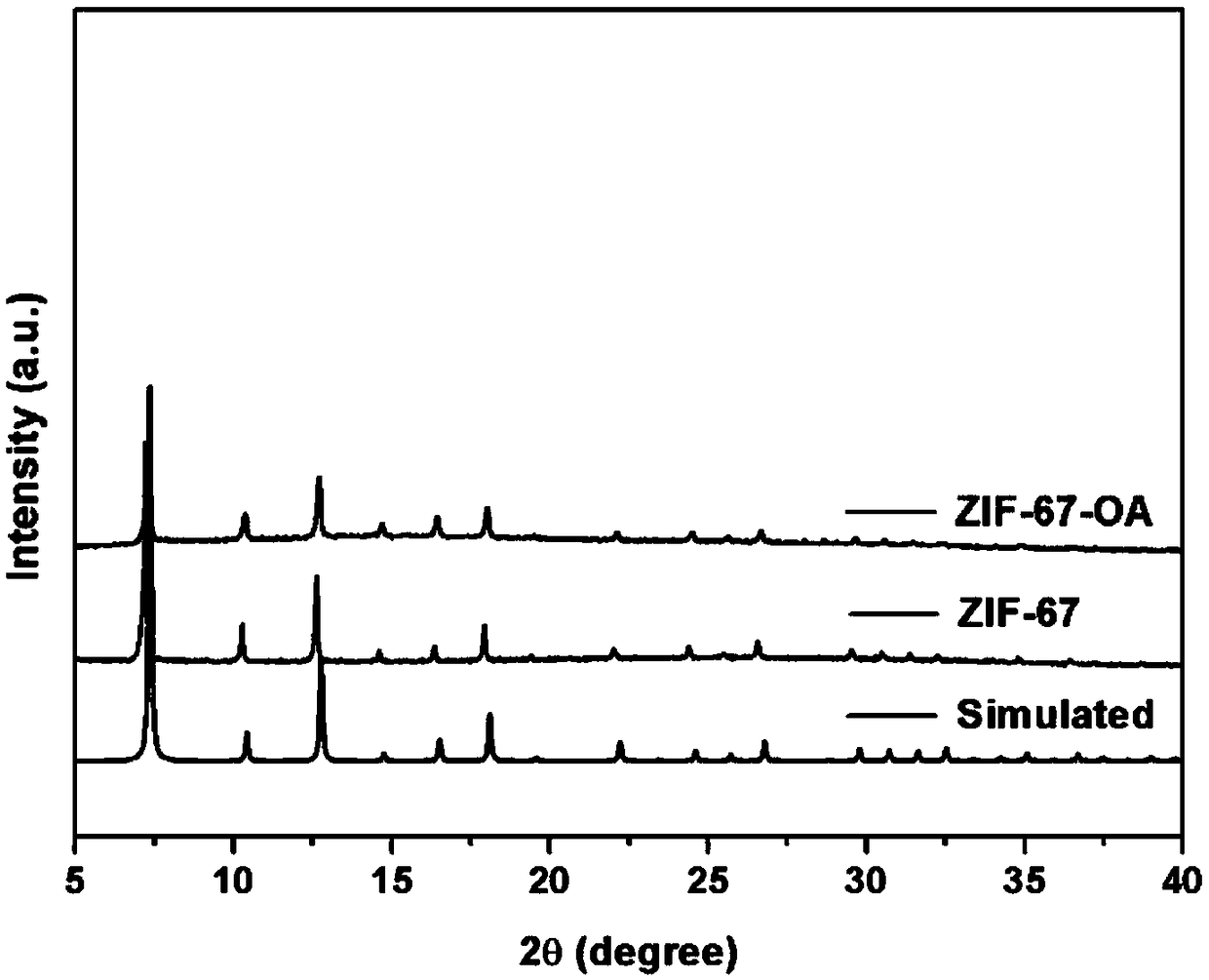

[0044] 1. Preparation of metal organic framework material ZIF-67

[0045] ZIF-67 was prepared by room temperature solvothermal method. First, weigh 0.5g Co(NO 3 )2 ·6H 2 Dissolve O in 3mL ultrapure water to obtain solution A; weigh 5g of dimethylimidazole and dissolve it in 50mL of anhydrous methanol to obtain solution B after dissolving. After the above two reaction precursors were completely dissolved, solution A was quickly poured into solution B under vigorous stirring to obtain a purple mixed solution, and then the mixed solution was magnetically stirred at room temperature for 24 h. After the obtained purple precipitate was separated by centrifugation, it was washed several times with absolute ethanol, and then vacuum-dried at 70°C overnight to obtain ...

Embodiment 2

[0066] The application of the metal-organic framework compound of embodiment 2 surface modification

[0067] (1) Chemical stability test

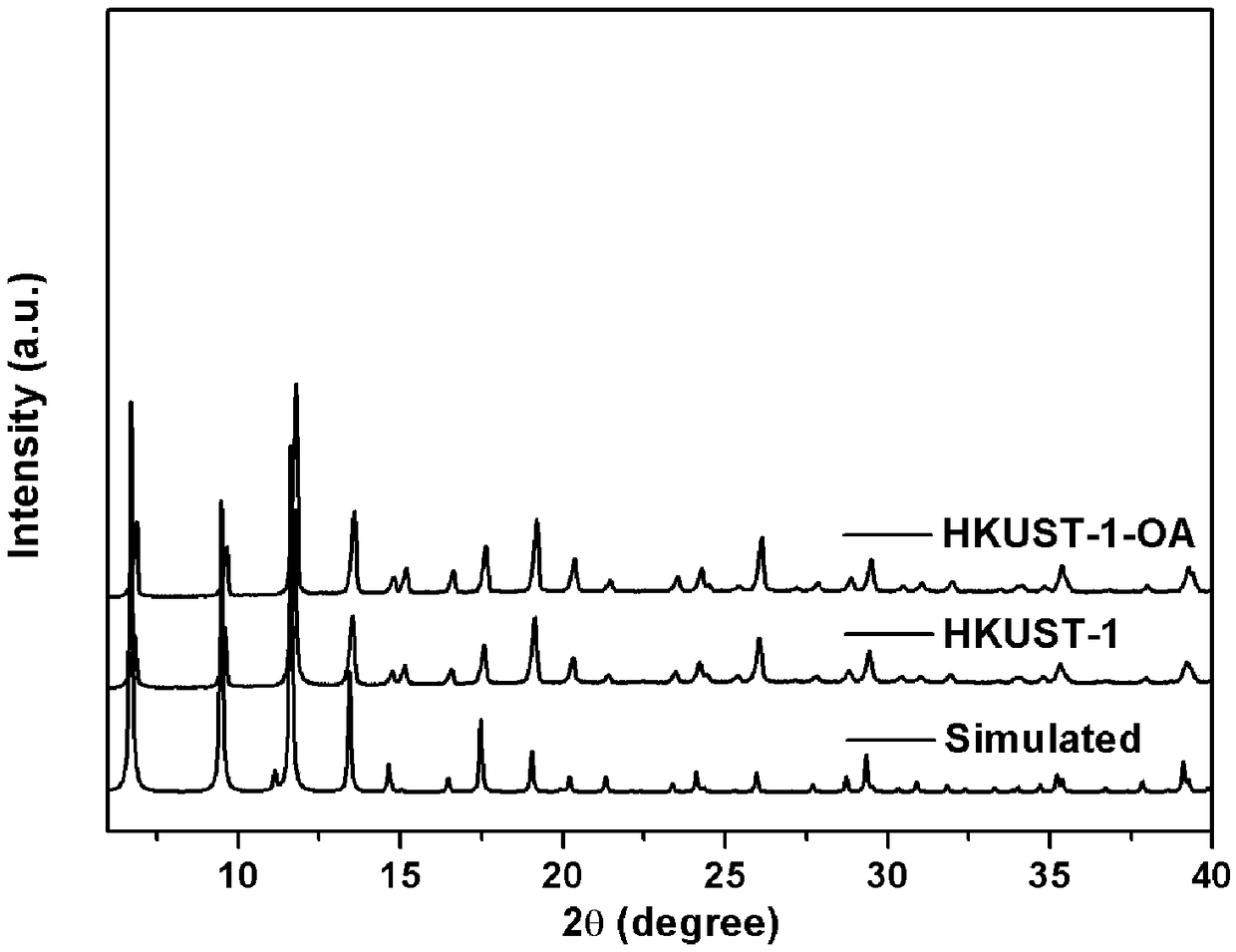

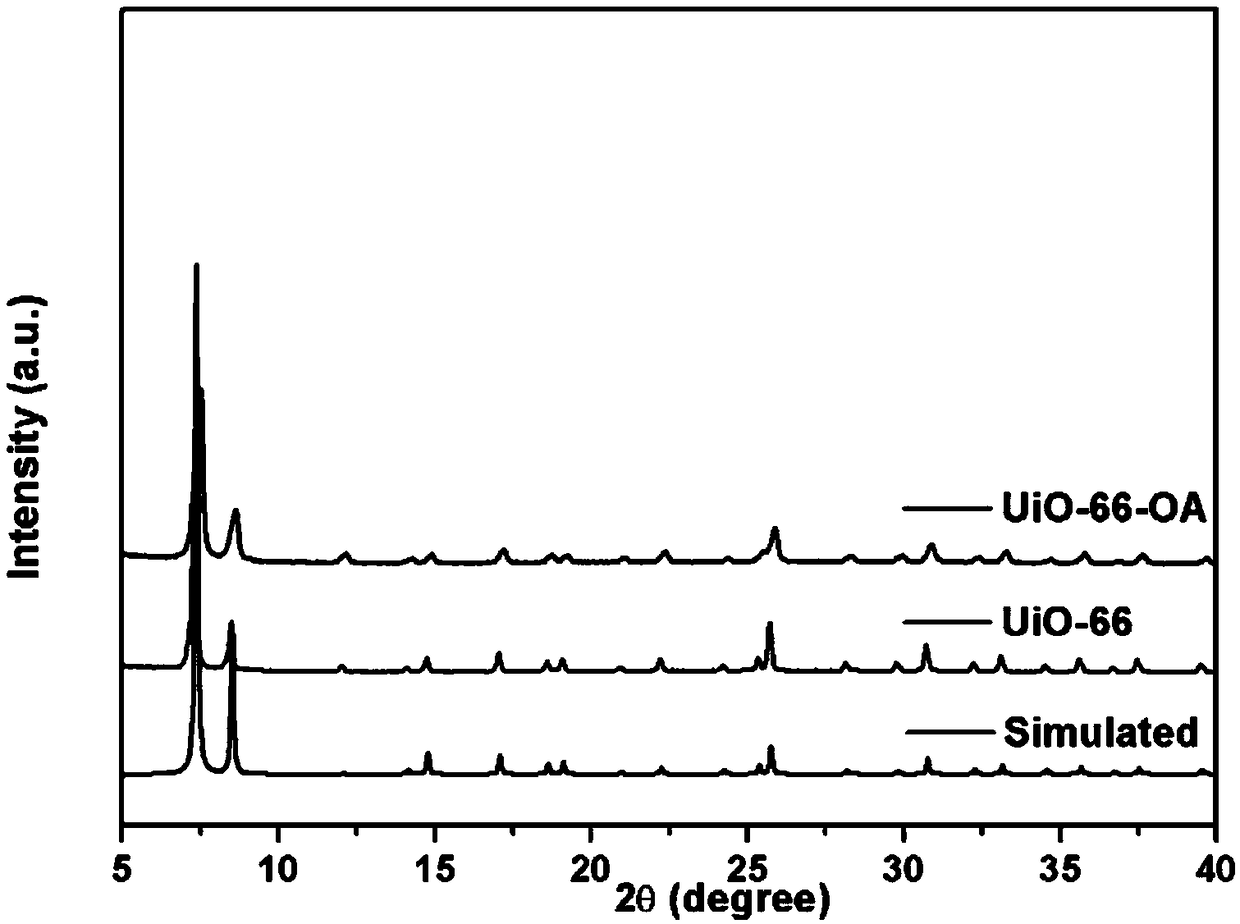

[0068] In order to investigate the chemical stability of the metal-organic framework compound modified based on octadecylamine, the obtained metal-organic framework compound modified based on octadecylamine was treated in different organic solvents. The specific process is: take 20 mg of the ZIF-67-OA complex, HKUST-1-OA complex and UiO-66-OA complex prepared in Example 1 and soak them in 10 mL of water and ethyl acetate; EA), toluene (Toluene), petroleum (Petroleumether; PE), n-hexane (n-hexane; Hex), (TCM chemical name) (TCM), (DCM chemical name) (DCM), ethanol (EtOH) and methanol ( MeOH), soaking at room temperature for 24h, and using infrared spectroscopy and PXRD to monitor the soaked composite.

[0069] 1. The PXRD of the metal-organic framework composite based on the surface modification of octadecylamine after soaking is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com