Method used for separation and enrichment of thorium at high acidity with phosphonic acid group-containing chelated resin

A chelating resin and phosphonic acid-based technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems affecting the adsorption capacity of thorium and the limited number of functional groups, and achieve fast adsorption speed , The preparation method is simple and the effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Chelating resin containing phosphonic acid group can be prepared by solvothermal method, as a typical synthetic example: 0.5g hydrogen phosphate di(methacryloyloxyethyl) ester and 0.05g azobisisobutyronitrile are added in 5ml tetrahydrofuran , stirred at 25°C for 1h, added the above solution into a hydrothermal reaction kettle, reacted at 100°C for 24h, took it out, opened the kettle, removed ethyl acetate by rotary evaporation, and dried in vacuum at 45°C for 12h to obtain the phosphine-containing Acid-based chelating resin1.

Embodiment 2

[0034] Chelating resin containing phosphonic acid group can be prepared by solvothermal method, as a typical synthetic example: 0.5g hydrogen phosphate bis(methacryloyloxyethyl) ester and 0.05g azobisisobutyronitrile are added in 5ml acetone , stirred at 25°C for 1h, added the above solution into a hydrothermal reaction kettle, reacted at 100°C for 24h, took it out, opened the kettle, removed ethyl acetate by rotary evaporation, and dried in vacuum at 45°C for 12h to obtain the phosphine-containing Acid-based chelating resin2.

Embodiment 3

[0036] Accurately pipette 25mL, 100mg / L thorium standard solution into a 150mL Erlenmeyer flask, use 12mol / L nitric acid, 1mol / L NaOH solution and 5mol / L NaOH solution to adjust the uranium solution H + concentration, so that the solution H + The concentration is 4mol / L. Add 0.010 g of adsorbent 1, and adsorb for 3 hours at 25 ° C, 135 r / min constant temperature oscillator. Separation by filtration, spectral analysis by ICP-OES, measurement of the concentration of thorium ions in the filtrate, and calculation of the adsorption capacity at this time by formula (1) is 59.5 mg / g.

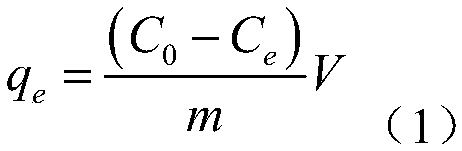

[0037] The adsorption amount of thorium ions is calculated according to the following formula:

[0038]

[0039] In the formula: q e - adsorption capacity, mg / g; V - volume of solution, L; C e - Equilibrium concentration of thorium ion solution, mg / L; C 0 - initial concentration of thorium ion solution, mg / L; m - mass of adsorbent, g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com