Production system for producing bromide by neutralization method

A production system and technology of bromide, applied in the direction of bromide preparation, hydrogen bromide, bromine/hydrogen bromide, etc., can solve the problem that it is difficult to produce high-concentration hydrobromic acid in large quantities, and hydrobromic acid cannot meet the requirements of bromination Response production, low production efficiency and other problems, to achieve the effect of improving acidification oxidation efficiency, prolonging contact time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

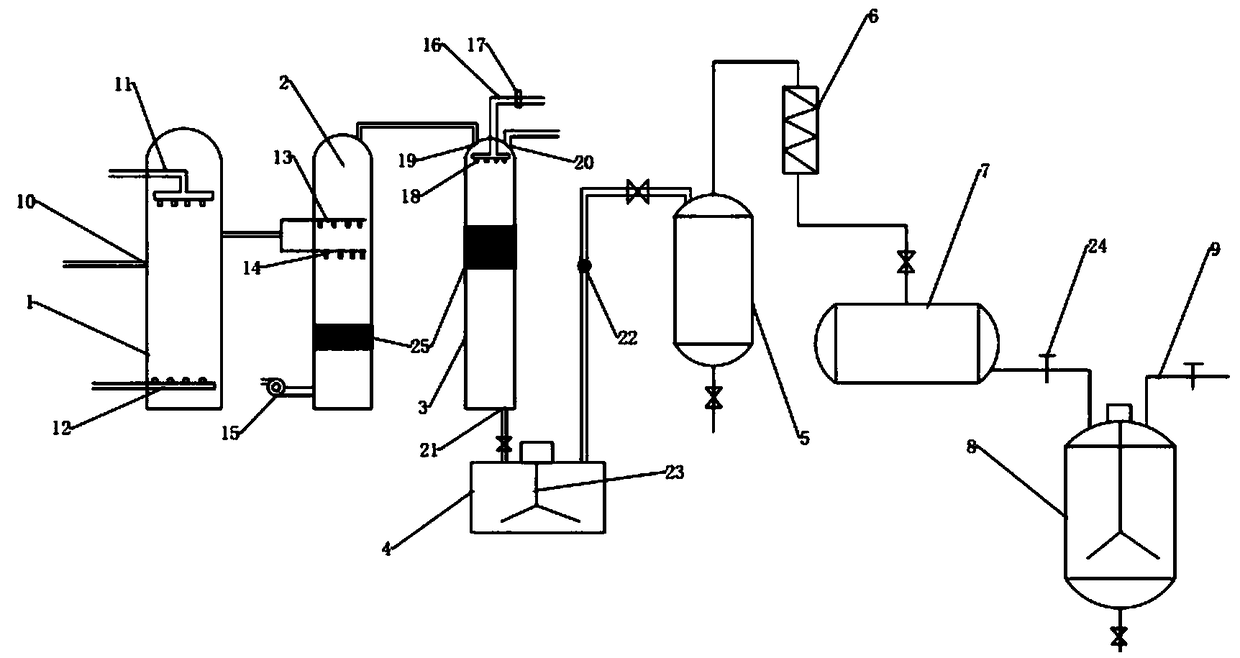

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the accompanying drawings.

[0020] like figure 1 Shown a kind of neutralization method produces the production system of bromide, comprises mixing reactor 1, blowing tower 2, absorption tower 3, dehydration tank 4 and distillation tower 5 that are communicated successively by pipeline, and the top of described distillation tower 5 is connected At one end of the condenser 6, the other end of the condenser 6 is connected with a hydrobromic acid storage tank 7, and the hydrobromic acid storage tank 7 is connected to the bromination reaction still 8 through the hydrobromic acid pipeline, and the bromination reaction The top of the kettle 8 is connected with a lye pipeline 9;

[0021] The mixing reactor 1 is provided with a brine inlet 10, a chlorine gas inlet, an acid inlet and an acidified and oxidized brine outlet, and an acid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com